Tower screw shell tail removing device

A technology of conical snails and cutting devices, which is applied in the fields of crustacean processing, slaughtering, food science, etc., and can solve problems such as heavy workload, increased labor, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

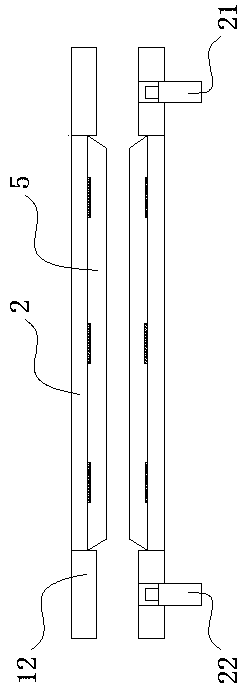

[0025] In this embodiment, in order to detect whether the screw body fills the chute, the upper end of the chute is provided with a photoelectric sensor that senses the screw body. When the photoelectric sensor senses that the screw body is located at this end, the photoelectric sensor is connected to the controller and Control the closing of the upper electromagnetic telescopic device so that the rear screw body does not move, and the opening of the upper lock pin is opened after the lock pin is closed under the control of the controller. This embodiment can realize automatic locking and work, reducing labor Intervention is easier to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com