Dry lotus root digging structure

A technology of digging claws and digging blades, which is applied in the agricultural field, can solve problems such as low labor productivity, large amount of ground breaking, and large traction resistance, and achieve the effects of saving manpower and material resources, small amount of ground breaking, and small traction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

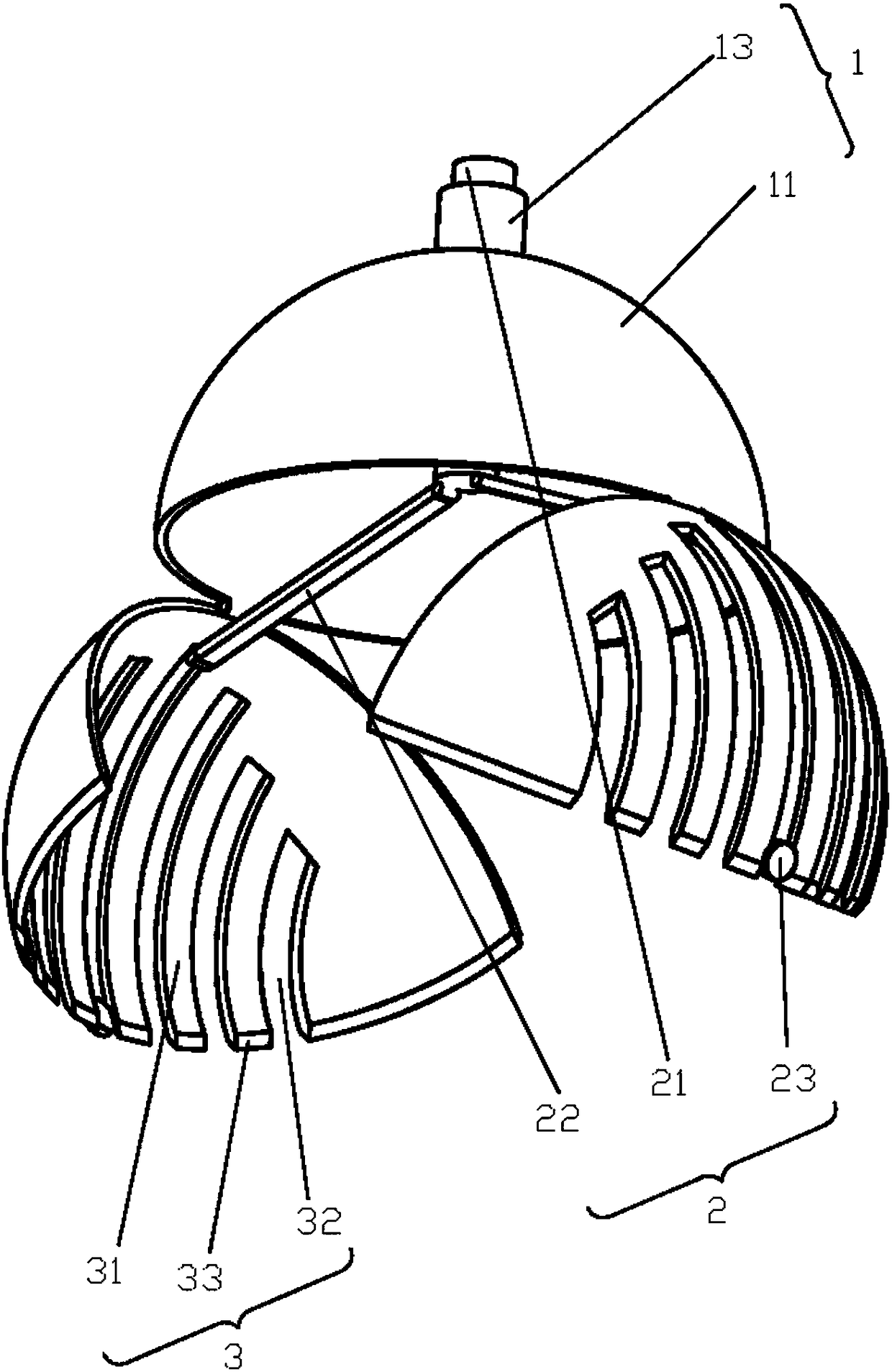

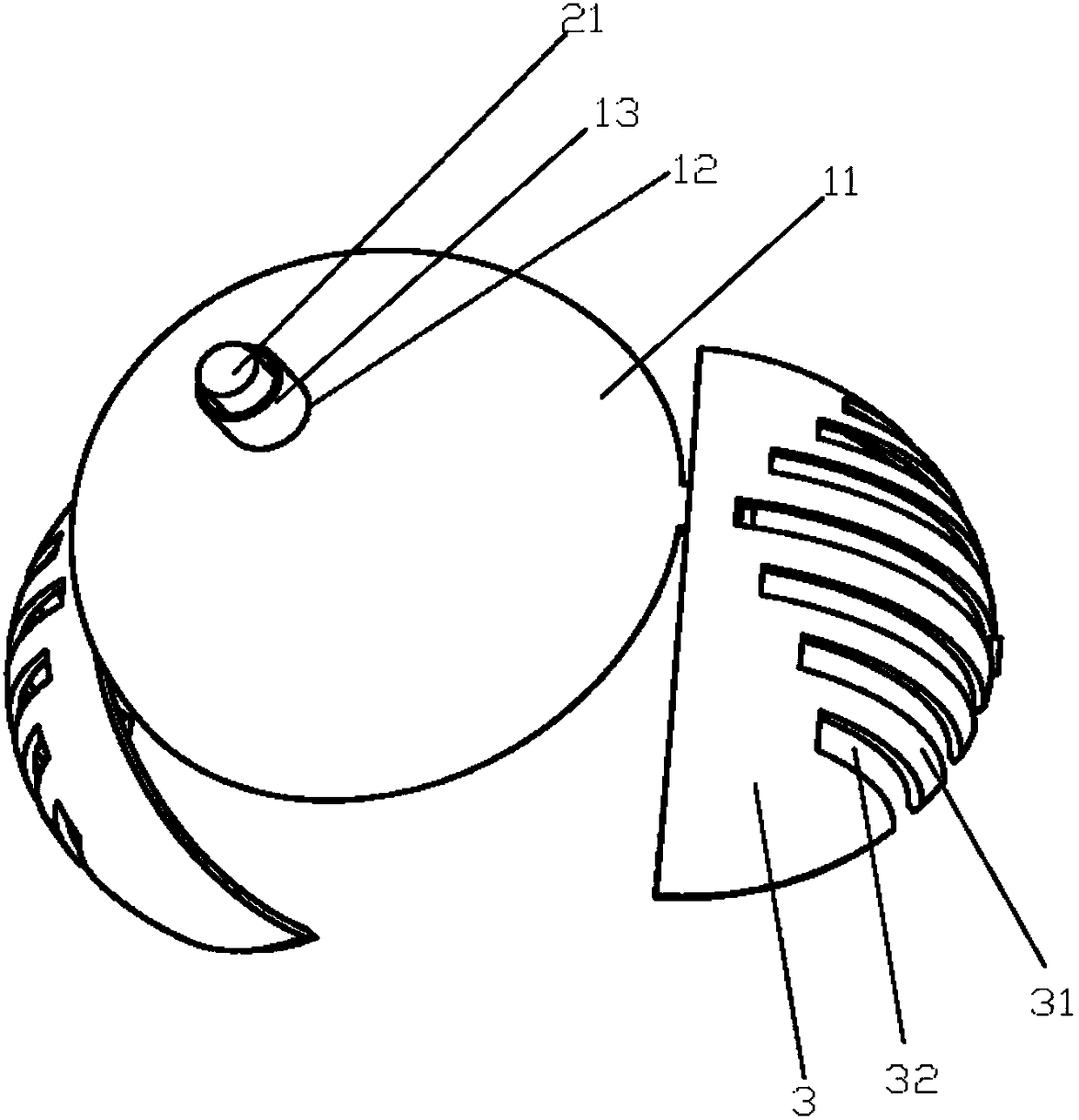

[0020] Combination hint Figure 1-2 , a structure for digging dry lotus root, comprising a fixed cover mechanism 1, a movable frame 2 and two movable skip pans 3, the fixed cover mechanism 1 includes a fixed cover 11, a telescopic groove 12, a fixed cover sleeve 13, the fixed cover mechanism 1 The cover 11 is hollow hemispherical, and the top is provided with the telescopic slot 12, the fixed cover sleeve 13 is a hollow cylinder and fixedly installed in the telescopic slot 12 on the top of the fixed cover 11, the movable skip The disc 3 is a quarter hollow sphere, and the movable skip disc 3 is provided with a plurality of digging claws 31, and the adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com