A kind of stepped support method for foundation pit in soft soil

A stepped and soft soil technology, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of difficult formation of support sections, less excavation, and unusability, so as to improve shear strength, save construction costs, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

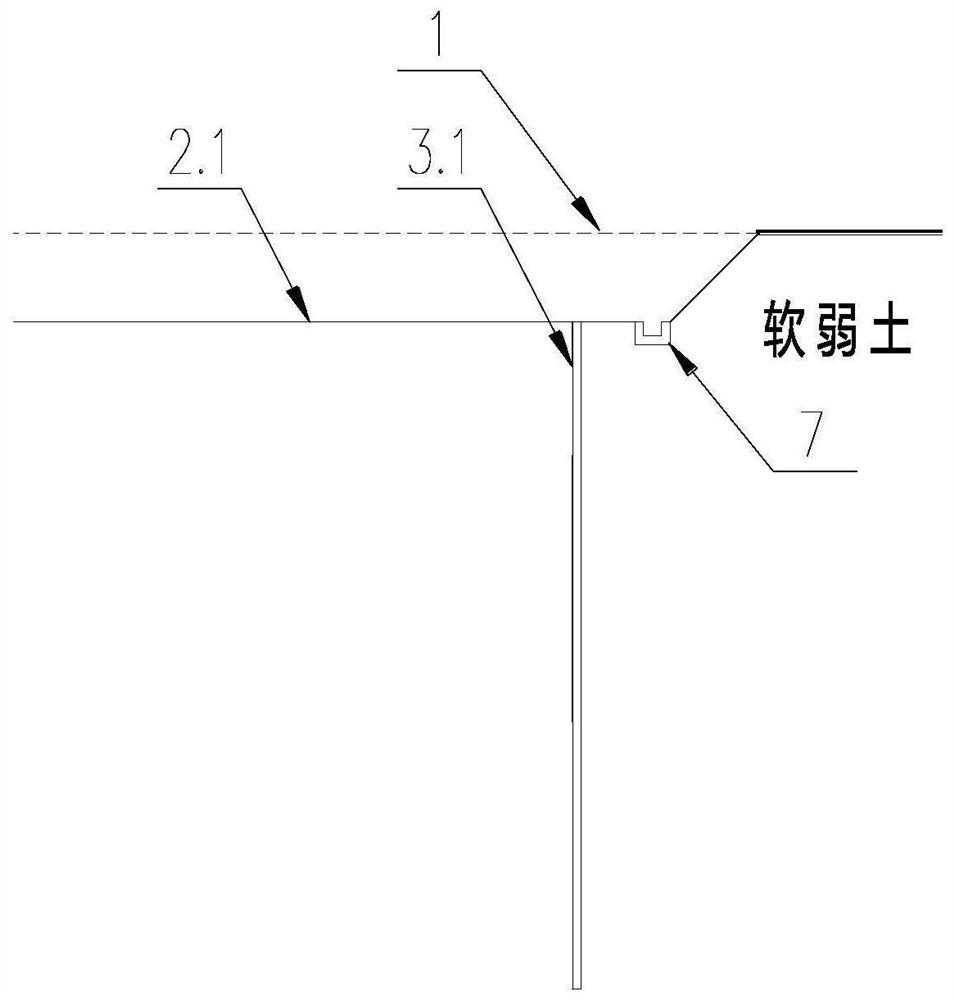

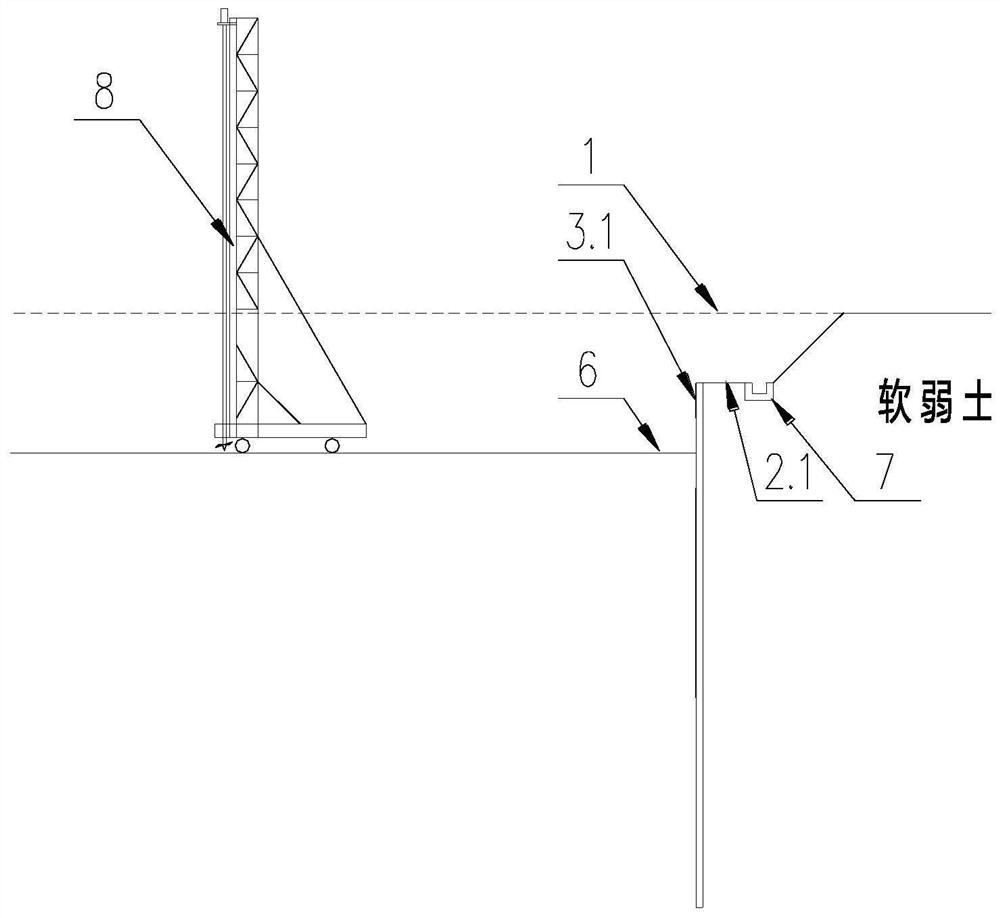

[0046] The following specific examples illustrate the present invention in further detail. figure 1 It is a construction diagram of the existing technology for the foundation pit of the Dayuanzi Pumping Station, which has been described in detail in the background technology, and will not be repeated here.

[0047] The present invention provides a kind of soft soil foundation pit step support method, the bottom elevation of the foundation pit 5 is 10m away from the depth of the original ground 1, and the steps are:

[0048] a. If figure 2 As shown, the original ground 1 is naturally sloped and excavated at a depth of 2m to form a first-level platform 2.1, and an intercepting ditch 7 is set at the bottom of the slope. The first-level steel sheet pile 3.1 is vertically driven on the first-level platform 2.1, and the first The steel sheet pile 3.1 forms a closed area along the circumference of the foundation pit 5, and the top of the first-level steel sheet pile 3.1 is flush wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com