A Self-installation Datum Equal Normal Gear Involute Model

An involute and common normal technology, applied in the field of common normal gear involute template, can solve the problem of not mastering the first-grade precision gear involute template, and achieve the effect of ensuring the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

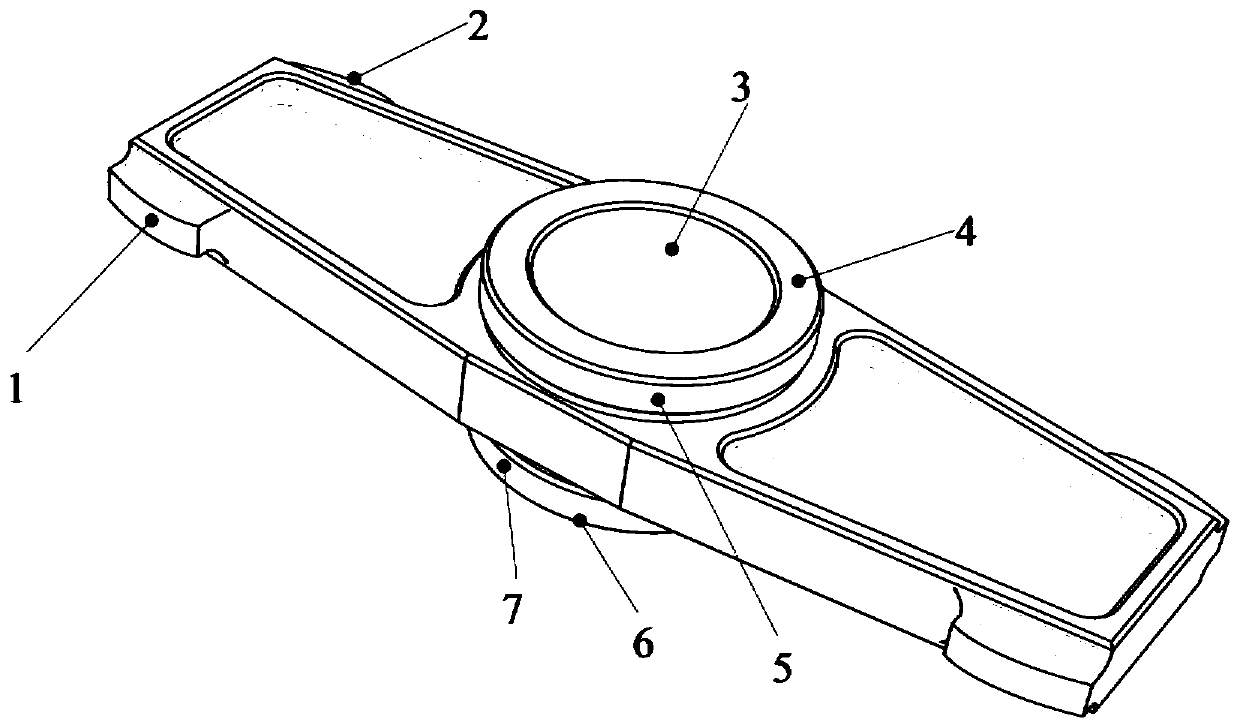

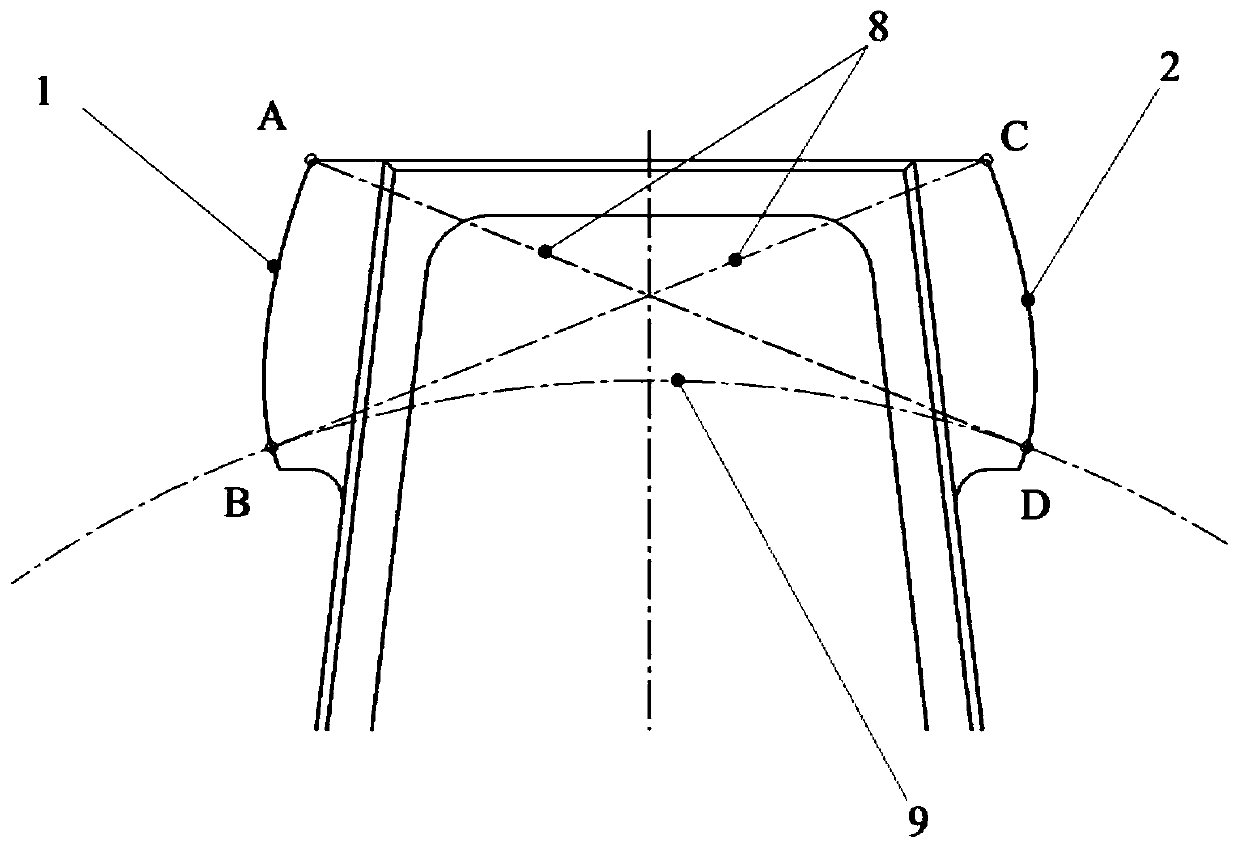

[0013] The self-installation datum equinormal gear involute model provided by the present invention has a structure including: left tooth surface 1, right tooth surface 2, datum hole 3, upper end face 4, lower end face 5, upper datum cylindrical face 6, lower datum cylinder Surface 8.

[0014] The involutes of the left and right tooth surfaces 1 and 2 have the same public normal 8 and a uniform base circle arc Any arc with the base circle The tangent normals are the common normals of the left and right tooth surfaces 1 and 2.

[0015] The design expansion angle of the gear involute template, that is, the arc of the base circle The central angle of the center angle should be greater than the expansion angle recommended in the national standard GB / T 6467-2010 for gear involute templates; and the measured tooth profile of the gear involute template should be given from the base circle. Since the involute close to the base circle is very sensitive to its expansion length, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com