Systems and methods of preventing run-away state in industrial machine

A technology of industrial machinery and computer, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as machine out of control, industrial machinery or other equipment damage, loss of motion control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

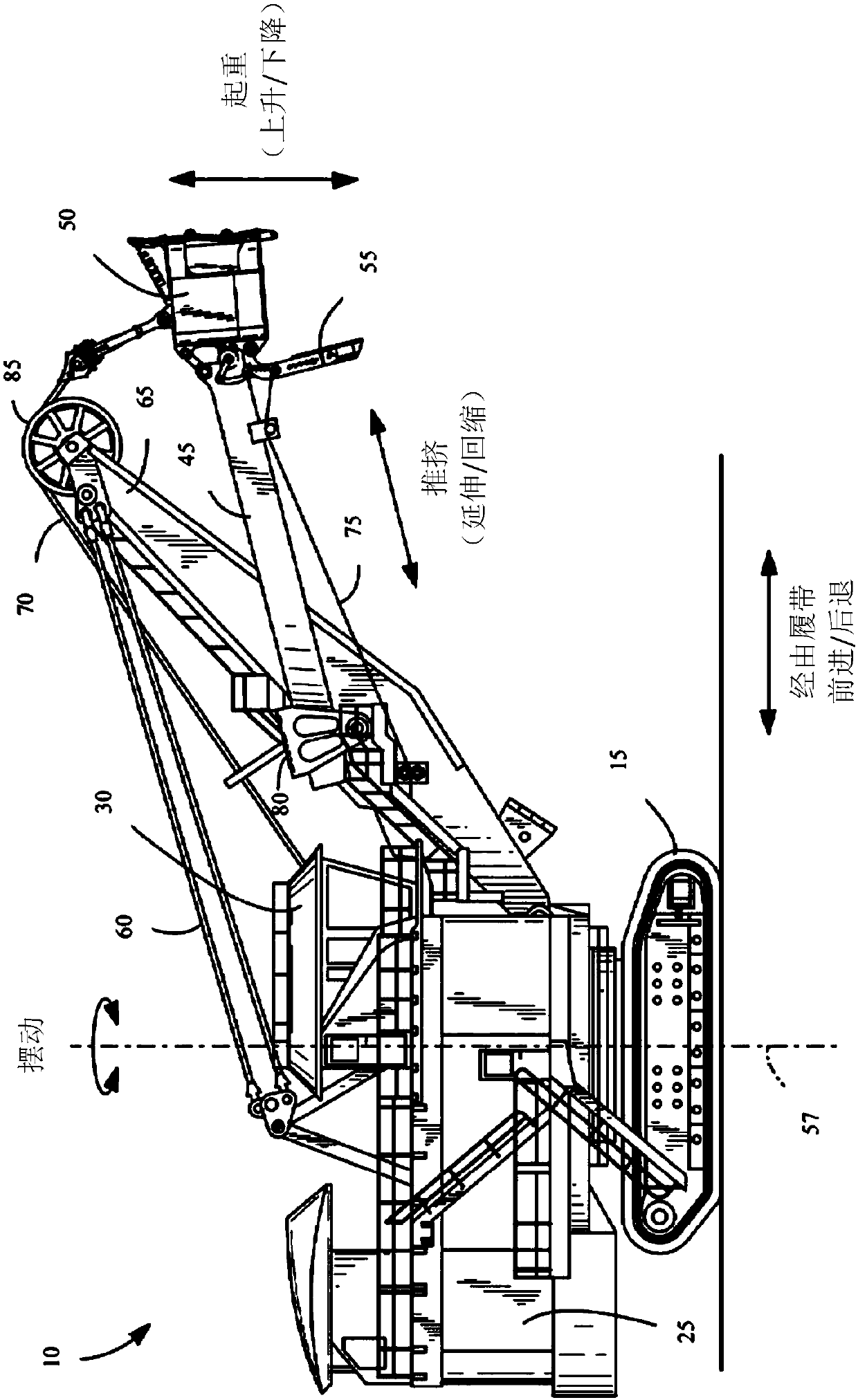

[0020] Although the invention described herein can be applied to, performed by, or used in conjunction with various industrial machines (e.g., rope shovels, draglines, AC machines, DC machines, etc.), Embodiments of the invention are described herein with respect to electric rope or power shovels, such as figure 1 The power shovel 10 is shown. The power shovel 10 includes tracks 15 for propelling the shovel 10 forward and rearward and turning the rope shovel 10 (ie, by changing the speed and / or direction of the left and right tracks relative to each other). Tracks 15 support a base 25 containing a cab 30 . The rope shovel 10 also includes a pivotable dipper handle 45 and an attachment 50 . In this embodiment, the attachment 50 is shown as a bucket. The attachment 50 includes a door 55 for pouring the contents of the attachment 50 . Movement of the crawler belt 15 is not necessary for the pivoting movement. The base 25 is able to swing or swivel relative to the track 15 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com