A method and system for setting up blind ditches for leachate stratification and drainage in landfills

A landfill and landfill leachate technology, which is applied in the field of waste landfill seepage, can solve the problems of height impact, bending or breaking, and easy blockage of blind ditch pipes, so as to achieve simple excavation and avoid pipe blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

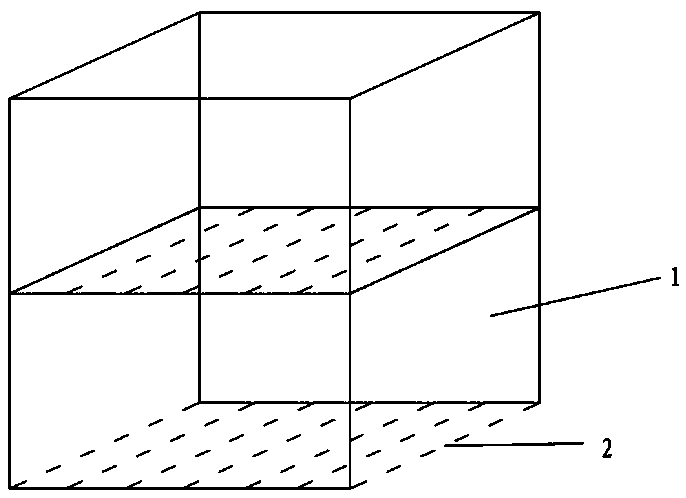

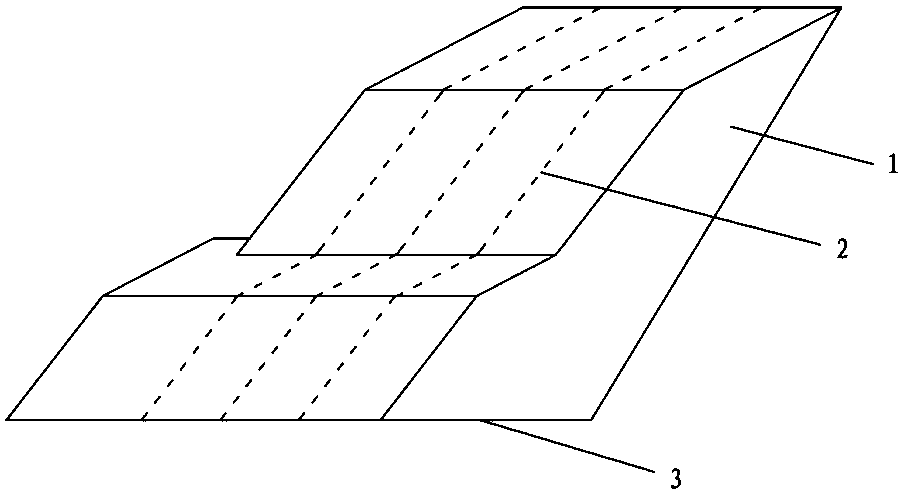

[0053] Taking a case of setting layered blind ditches in the middle landfill operation area of a valley-type landfill, the specific construction area is a garbage dump with 4 or more layers of garbage, such as figure 2 , image 3 As shown in the figure, the garbage on the 4th floor and above is not drawn, figure 1 as a landfill unit, Figure 2-3 The figure shows the three layers of different garbage operation surfaces and the blind ditch at the bottom of the first layer of garbage respectively arranged in the garbage landfill area, the details are as follows:

[0054] (1) When filling the first layer of garbage, dig a blind ditch at the bottom of the first layer of garbage to guide the leachate of the first layer of garbage; when filling the second layer of garbage, excavate on the surface of the first layer of garbage The blind ditch is used as the leachate of the second layer of garbage to guide and drain the blind ditch, and so on. When filling the third layer of garba...

specific Embodiment 2

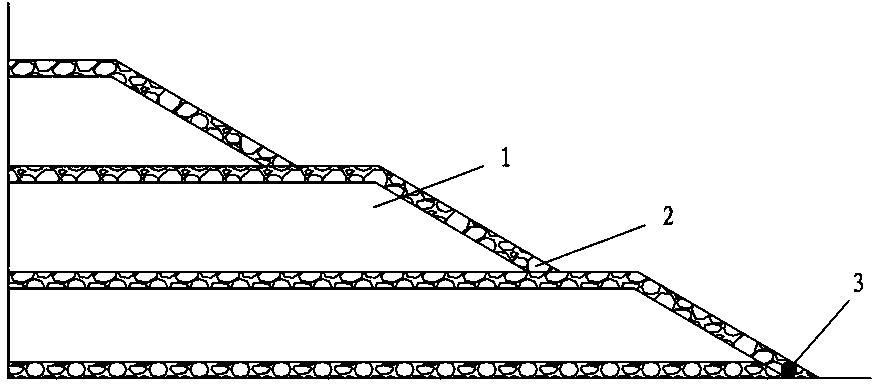

[0066] Taking a case of setting layered blind ditches in the middle landfill operation area of a valley-type landfill, the specific construction area is a garbage dump with 4 or more layers of garbage, such as figure 2 , image 3 As shown, the garbage on the 4th layer and above is not drawn in the figure. The figure shows the three layers of different garbage operation surfaces and the blind ditch at the bottom of the first layer of garbage respectively arranged in the garbage landfill area. The blind ditch is as follows: Figure 4 As shown, the details are as follows:

[0067] A leachate layered guiding and draining blind ditch system, comprising a layered landfill (1) and a corresponding layered guiding and draining blind ditch (2), characterized in that it is opened in the first layer of garbage The ditch at the bottom is used for guiding the blind ditch (2) of the first layer of garbage, and several ditches set on the surface of the Nth layer of garbage are used for gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com