Dry and wet forage separation and recovery vehicle for farm and its use method

A technology of separation and recovery, farms, applied in the direction of solid separation, chemical instruments and methods, classification, etc., can solve the problems of dry and wet separation and screening of abnormal forage, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

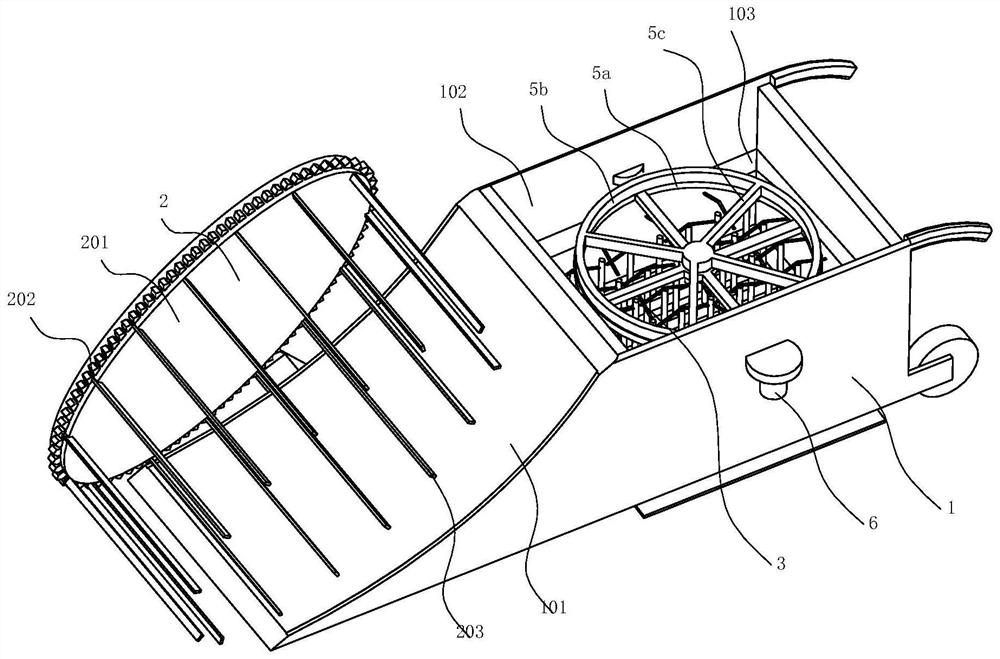

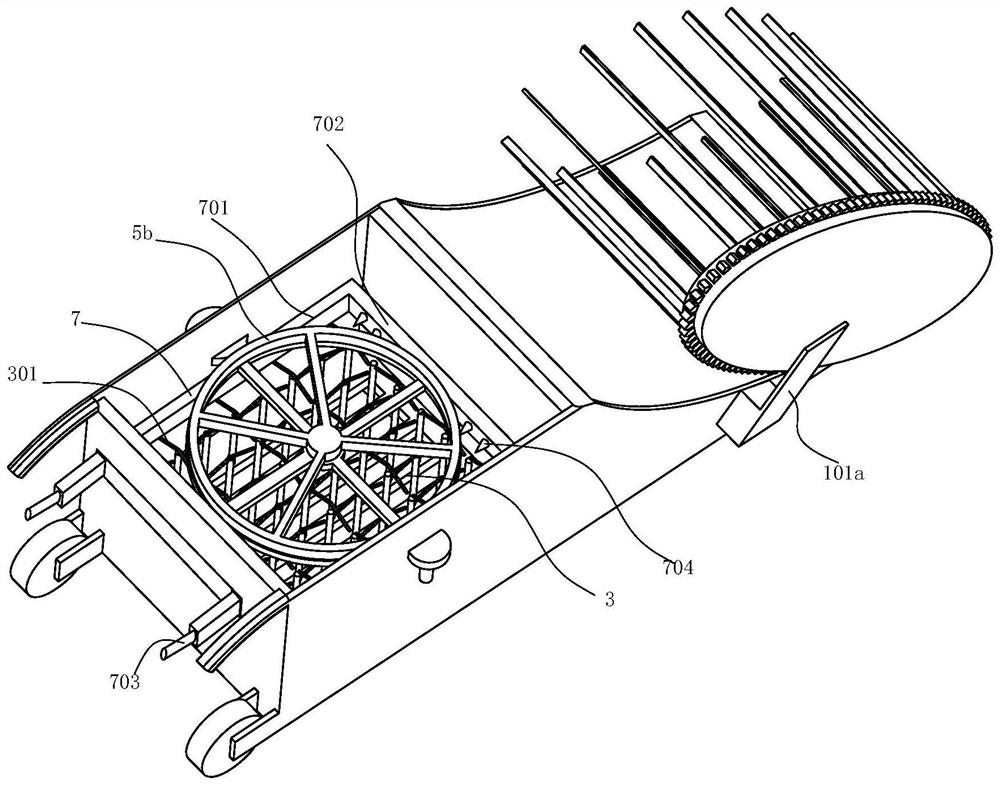

[0044] Such as Figure 1 to Figure 6 As shown, the dry and wet forage separation and recovery vehicle of the breeding farm includes a car body 1, and a shovel 101 is installed at the front end of the car body 1. Since the forage is usually placed on the ground of the warehouse, or on the ground of the cowshed, the setting of the shovel 101 The burden of manually carrying the forage is reduced. The upper side of the shovel plate 101 is a concave curved surface to better shovel and store the forage; Forage in the rear.

[0045]In order to further dial the forage to the top of the car body 1, the present embodiment installs a feed rack 2 for dialing the grass into the car body 1 on the shovel plate 101. The feed rack 2 includes a frame body 201 and is wound around the frame body 201 A rotary sleeve 202 that is mounted on and rotates around it and a paddle 203 installed on the rotary sleeve 202; one side of the shovel plate 101 is provided with a side vertical plate 101a of a fix...

Embodiment 2

[0060] On the basis that the scheme of Embodiment 1 remains basically unchanged, further, this embodiment fixes the column 401 on the support rod 4, and fixes the elastic needle 301 on the column 401, and the column 401 is in front of the support rod 4 and the elastic needle 301 A certain distance is formed, on the one hand, more fodder can be accumulated in the space below the elastic needles 301, avoiding frequent opening of the material box 102; A certain distance is staggered between the array faces, so that the overlapping degree of the two in the same horizontal plane is reduced, avoiding the formation of a large area of blocking, and affecting the smooth falling of the deteriorated forage.

[0061] For the effect of the column 401 in specific use, the inventor has obtained the following data through a large number of experiments: compared with the structure without the column 401, after the column 401 with a height of 7cm is used, the difference between the higher dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com