Method for analyzing load characteristics of induction motor under constant mechanical power

A technology of induction motors and mechanical power, applied to load forecasting, electrical components, circuit devices, etc. in AC networks, can solve problems such as inconsistency of calculation results, influence of simulation results, lack of accurate data on load composition, etc., to save calculation time and The workload, the calculation process is simple, and the effect of good application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

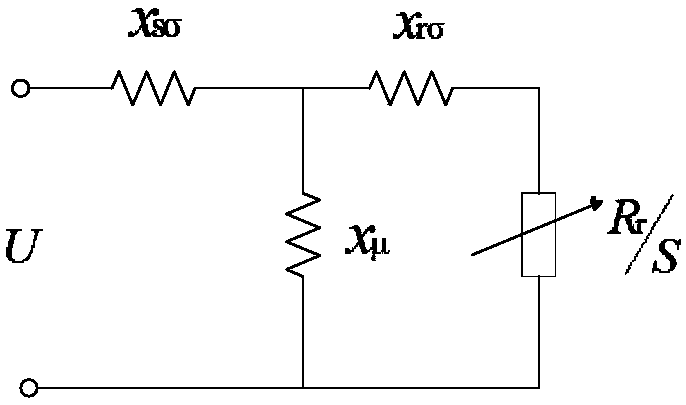

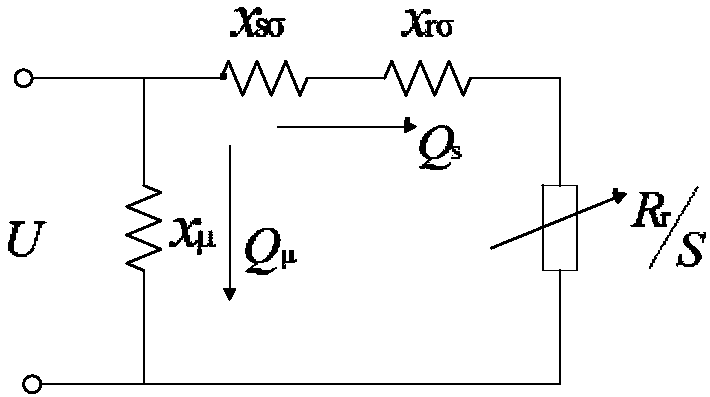

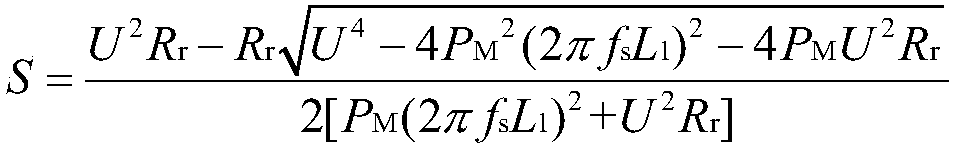

[0042] Embodiment 1: as Figure 1-2 As shown, a load characteristic analysis method of an induction motor with constant mechanical power calculates the slip rate of the induction motor under the condition of constant mechanical power; according to the relationship between the slip rate and frequency and voltage, the active power absorbed by the induction motor and The relational expression of reactive power; according to the obtained active power and reactive power, the partial derivative of the stator side frequency is calculated respectively, and multiplied by the ratio of the initial frequency to the initial power to obtain the expression of the frequency characteristic coefficient; according to the calculated The obtained active power and reactive power are respectively calculated for the partial derivative of the power supply voltage, and multiplied by the ratio of the initial voltage to the initial power to obtain the expression of the voltage characteristic coefficient; ...

Embodiment 2

[0046] Embodiment 2: as Figure 1-2 As shown, a load characteristic analysis method of an induction motor with constant mechanical power calculates the slip rate of the induction motor under the condition of constant mechanical power; according to the relationship between the slip rate and frequency and voltage, the active power absorbed by the induction motor and The relational expression of reactive power; according to the obtained active power and reactive power, the partial derivative of the stator side frequency is calculated respectively, and multiplied by the ratio of the initial frequency to the initial power to obtain the expression of the frequency characteristic coefficient; according to the calculated The obtained active power and reactive power are respectively calculated for the partial derivative of the power supply voltage, and multiplied by the ratio of the initial voltage to the initial power to obtain the expression of the voltage characteristic coefficient; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com