CNC machine tool control method and system

A technology of numerical control machine tools and control systems, applied in the field of numerical control, can solve problems such as the inability of effective data interaction between numerical control machine tools and computers, and achieve the effect of reducing the waste of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0025] The CNC machine tool control method provided by the embodiment of the present invention is applied to a CNC machine tool control system, and the CNC machine tool control system includes a terminal device communicatively connected to a host computer and a CNC machine tool communicatively connected to the terminal device. Among them, the upper computer is generally a remote device away from the part processing site, and the upper computer can be a mobile device such as a computer or a mobile phone. The terminal equipment is generally located at the part processing site, and the terminal equipment can also be a mobile device such as a computer or a mobile phone. CNC machine tools generally include multiple stations for processing parts. Different stations perform different processing procedures and can process different parts. Multiple stations can process at the same time, that is, multiple different parts can be processed at one time. Components.

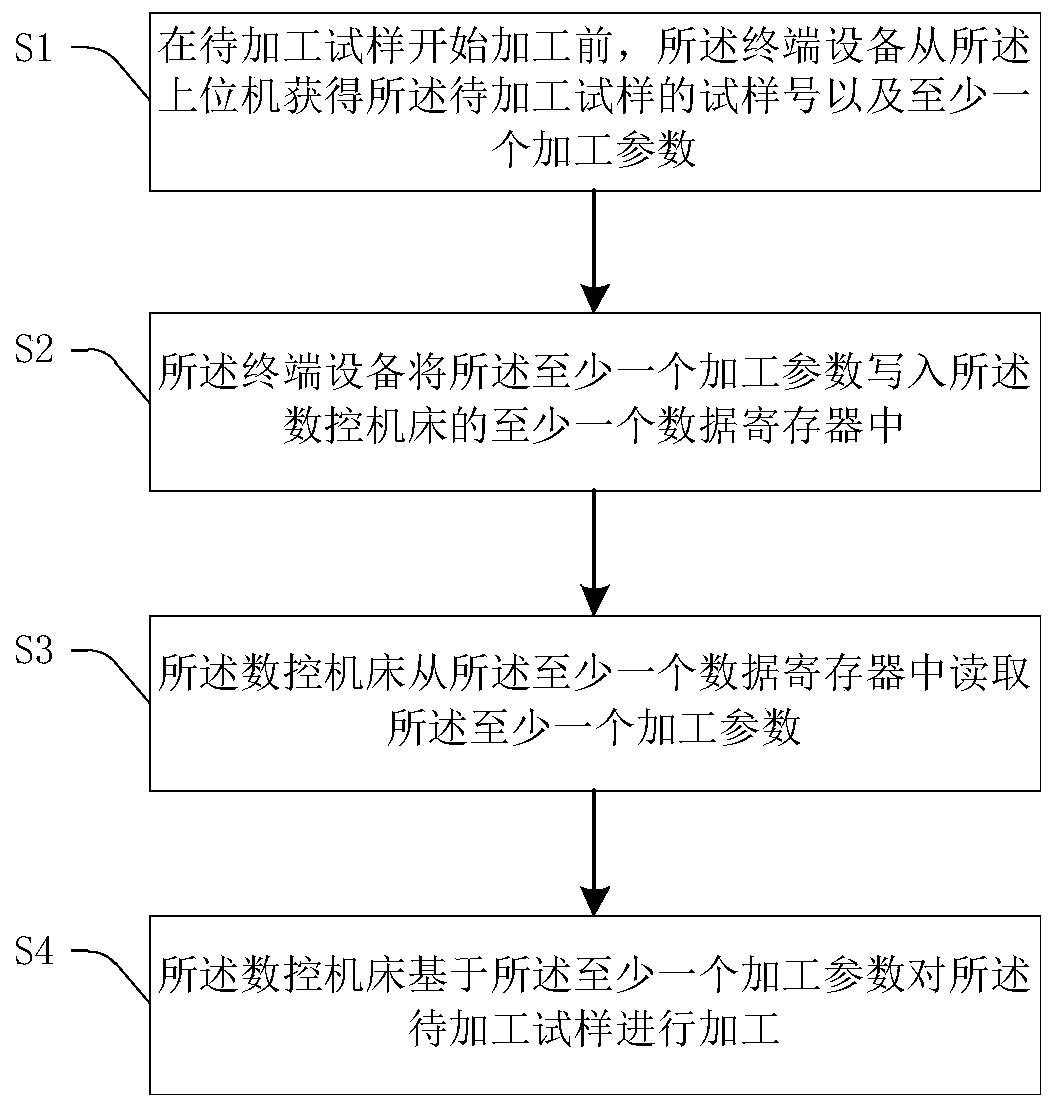

[0026] figure 1 A fl...

no. 2 example

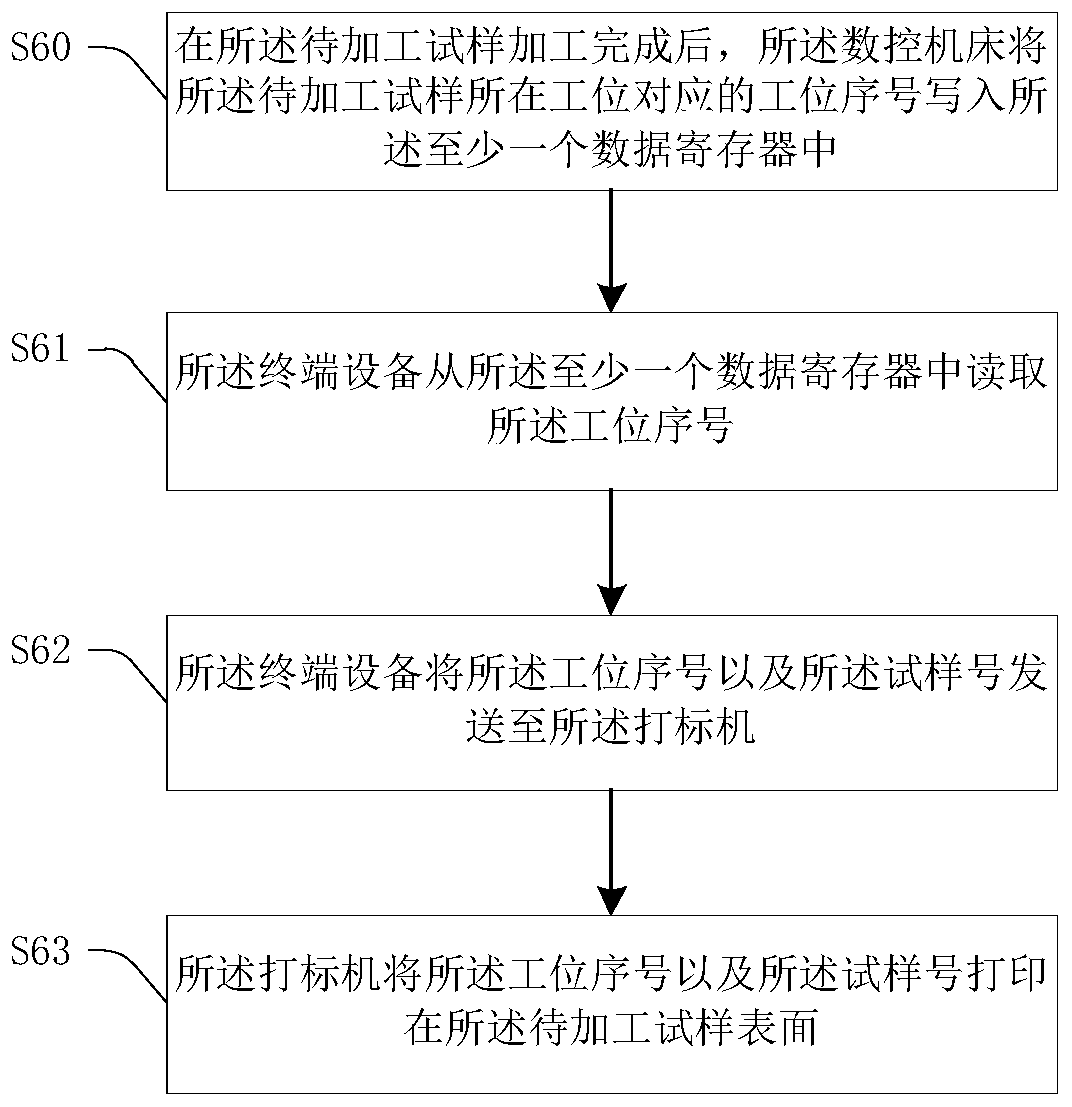

[0054] Figure 4 A structural block diagram of the CNC machine tool control system 100 provided by the embodiment of the present invention is shown. refer to Figure 4 , the CNC machine tool control system 100 provided by the embodiment of the present invention includes: a terminal device 110 connected in communication with the upper computer 200, a CNC machine tool 120 connected in communication with the terminal device 110, and a marking machine connected in communication with the terminal device 110 130. Wherein, the terminal device 110 is used to obtain the sample number and at least one processing parameter of the sample to be processed from the host computer after the sample to be processed is placed on the station of the numerical control machine tool 120, and , write the at least one processing parameter into at least one data register of the numerical control machine tool 120; the numerical control machine tool 120 is used to read the at least one processing paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com