A Bogie with Simple Structure

A bogie technology with a simple structure, applied in the direction of bogie, climate sustainability, railway transportation, etc., can solve the complex structure of the bogie, unfavorable bogie integration, lightweight reliability improvement, bogie manufacturing, assembly and other problems. Maintenance difficulties and other problems, to achieve the effect of improving reliability and high-speed running performance, lightweight structure, easy assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

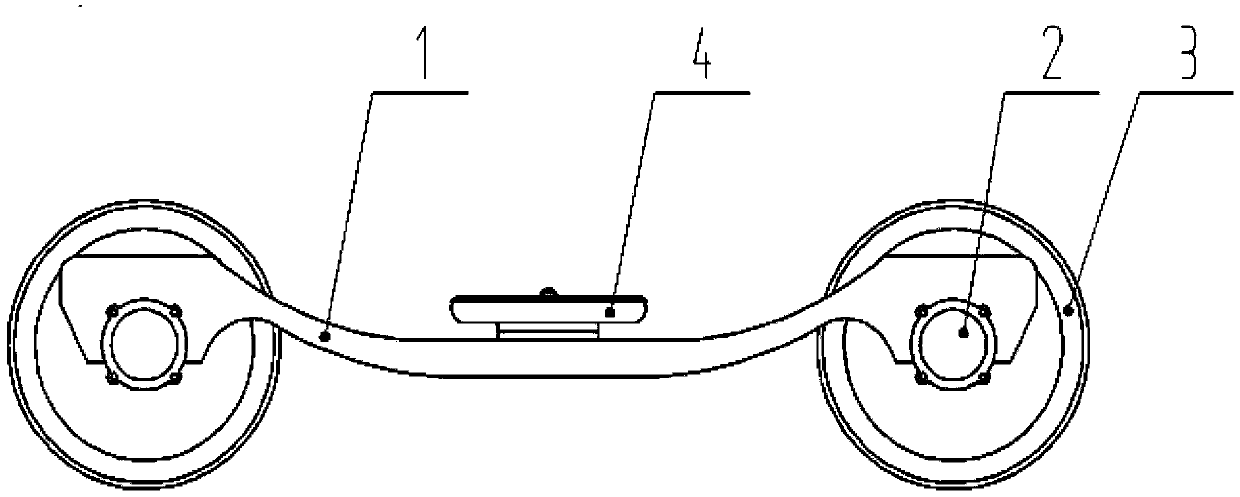

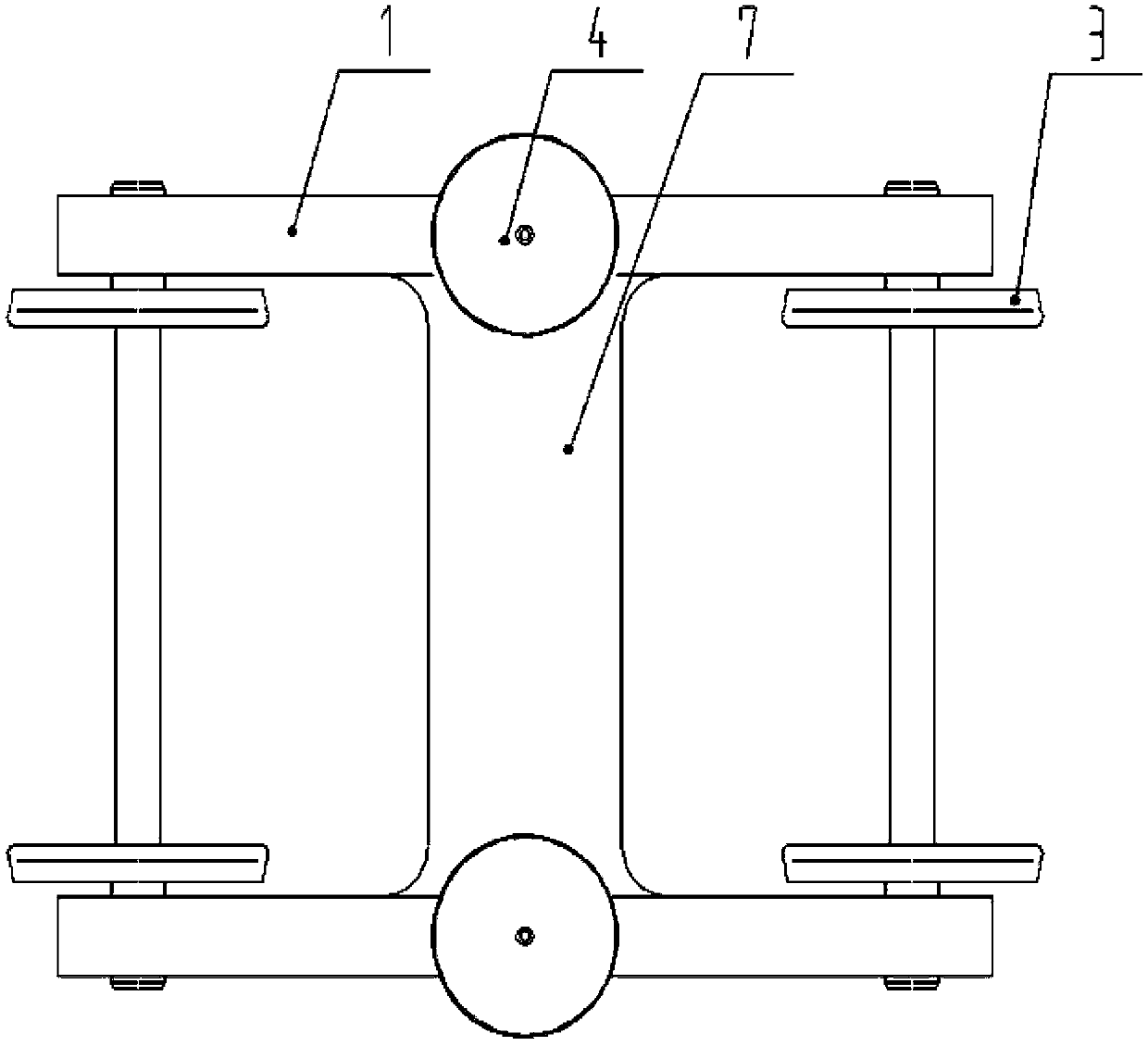

[0020] Such as figure 1 and image 3 As shown, the present embodiment is an integrated simplified structure, including two pairs of wheelsets 3, a framework including side beams 1 and cross beams 7, axle boxes 2 and secondary suspensions.

[0021] The bogie frame is an H-shaped frame, a side beam 1 is respectively arranged on both sides of the beam 7, and axle boxes 2 are installed at both ends of the axles of the wheel set 3. The two ends of the side beam 1 match the shape of the installation surface of the axle box 2, and are directly suspended on the axle box 2. There is no traditional primary suspension including a spring unit between the two, and a traditional axle box guide frame is used between the two The positioning method of the target.

[0022] The frame side beam 1 of the bogie is composed of a high damping material. Specifically, in this embodiment, it is composed of a Fe-Mn based composite damping alloy. This material has high strength, a tensile strength highe...

Embodiment 2

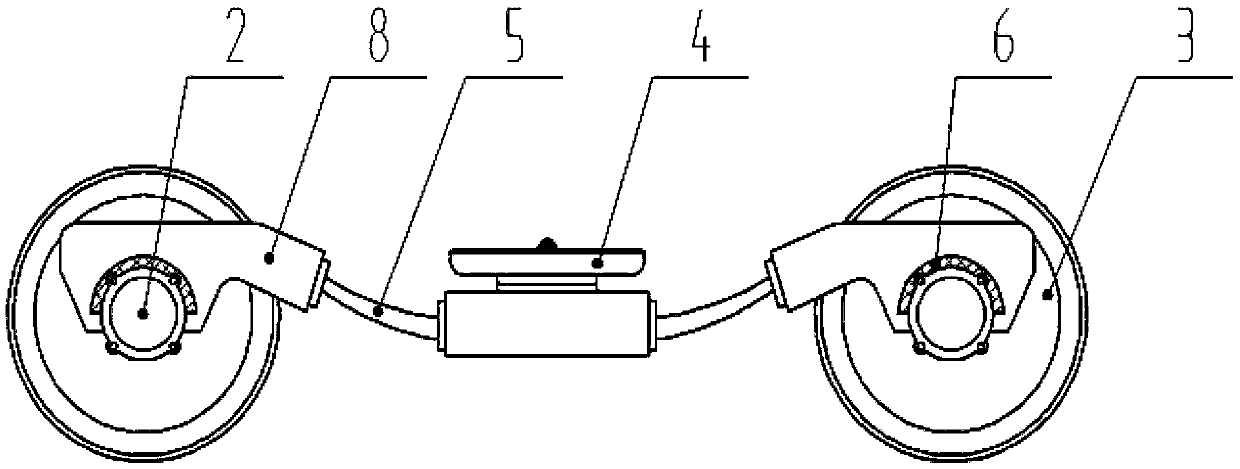

[0025] as attached figure 2 and Figure 4 As shown, the present embodiment is a combined simplified structure. The main difference is that the frame side beam 1 of embodiment 1 is an elastic beam as a whole, while the side beam 1 of this embodiment consists of two sections of flexible beam sections 5 and The three rigid beam sections 8 are fixedly connected, and carbon fiber material is used. This material itself has the characteristics of high flexural and shear strength, light weight, strong elastic deformation and recovery ability. Both ends of the flexible beam section 5 are connecting seats, and the middle is also a sheet structure. The connecting seats at both ends of the flexible beam section 5 are respectively connected with different rigid beam sections 8 to form the entire side beam 1 . The elasticity of the side beam 1 mainly comes from the elastic deformation of the flexible beam section 5 itself. An elastic damping layer 6 is installed at both ends of the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com