Side-hanging type air rail train bogie

A bogie and side-mounted technology, which is applied to bogies, elevated railway systems with suspended vehicles, devices for lateral relative movement between the underframe and bogies, etc., can solve problems such as small loads and poor vibration damping , achieve the effect of small turning radius, increase transportation capacity and save running space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

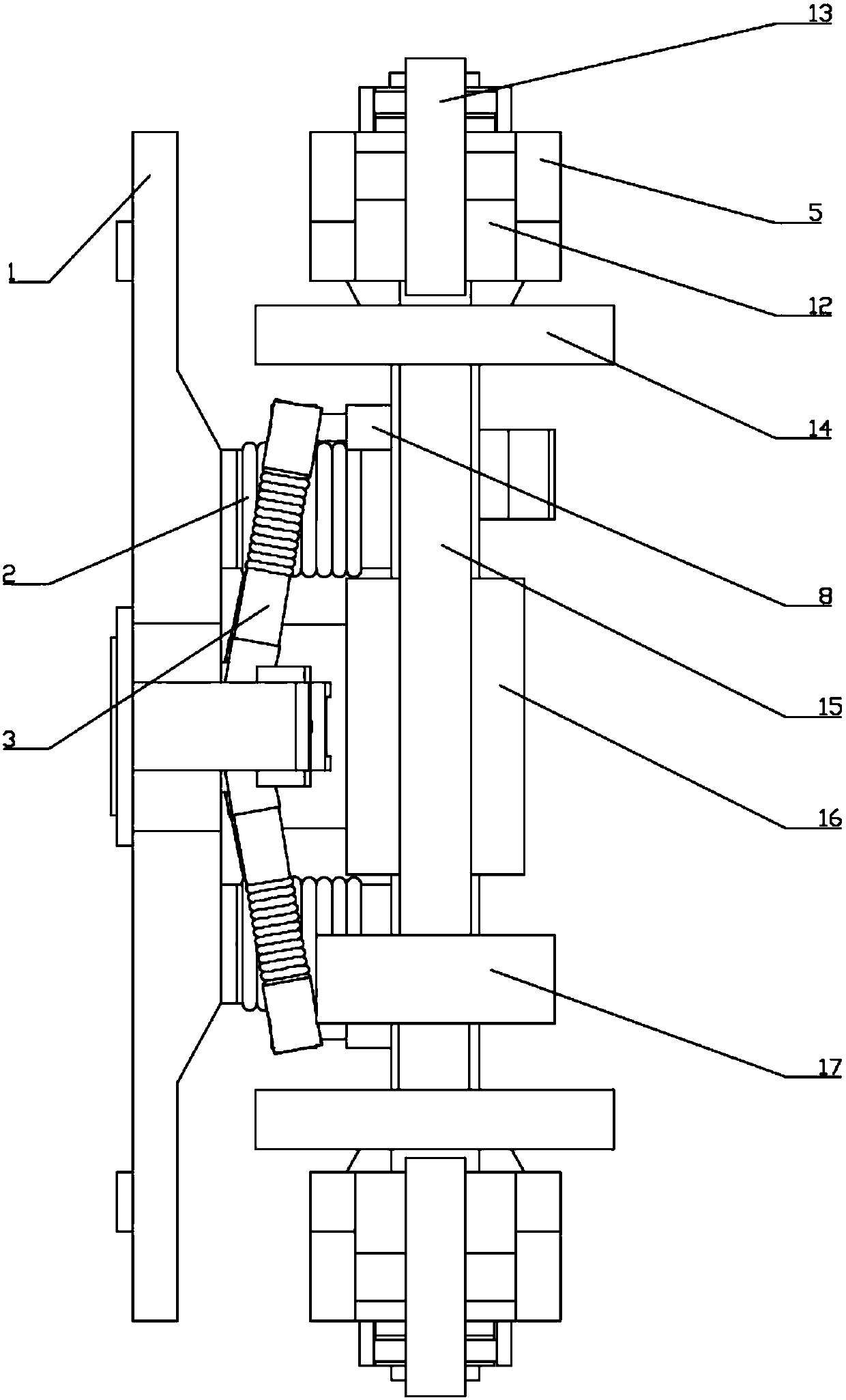

[0019] Such as figure 1 As shown, the side-mounted empty rail bogie of the present invention is mainly composed of bolsters 1 and the like. The bolster 1 is connected to the bogie frame 9 through a transverse spring 2, a vertical spring rod 3 and a traction rod 4, and each joint is hinged. The car body of the side-mounted empty rail vehicle is connected with the bolster 1, and the bogie is connected with the track through the transverse wheel 14 and the vertical wheel 13. Thus, the bogie system is the core of the entire side-mounted empty rail vehicle. The bogie in this example is mainly of welded construction. The frame 5 of the bogie is the basic structure of the bogie. Its structure is "I" shaped, mainly composed of two beams 5 arranged up and down and a longitudinal beam 10 in the center. Both ends of the beam 5 are equipped with vertical forks....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com