Angle bracket drilling jig

A drilling jig and foot code technology, which is applied in the direction of manufacturing tools, clamping, and supports, can solve the problems of misoperation, low yield, low production efficiency, etc., and achieves improved product yield, low manufacturing cost, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

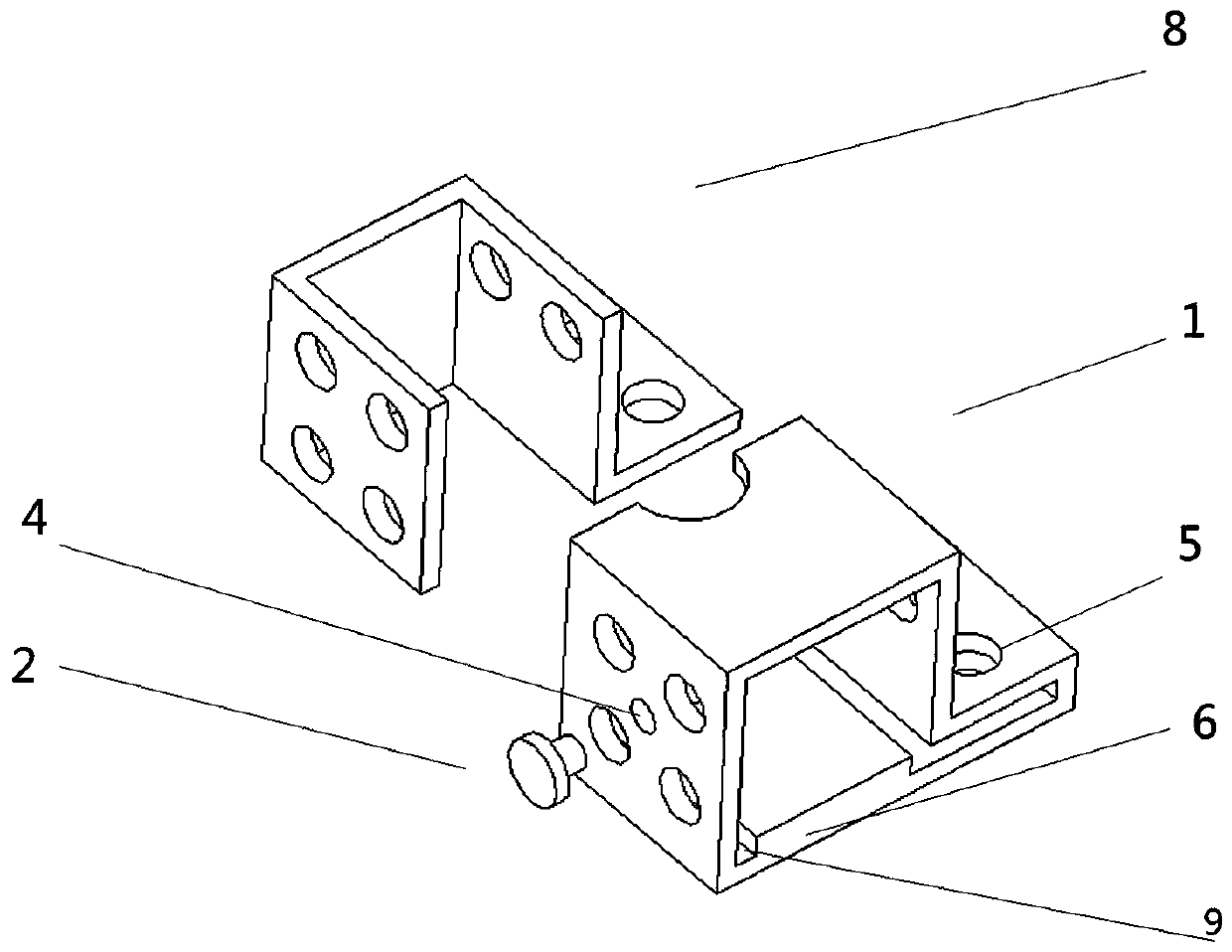

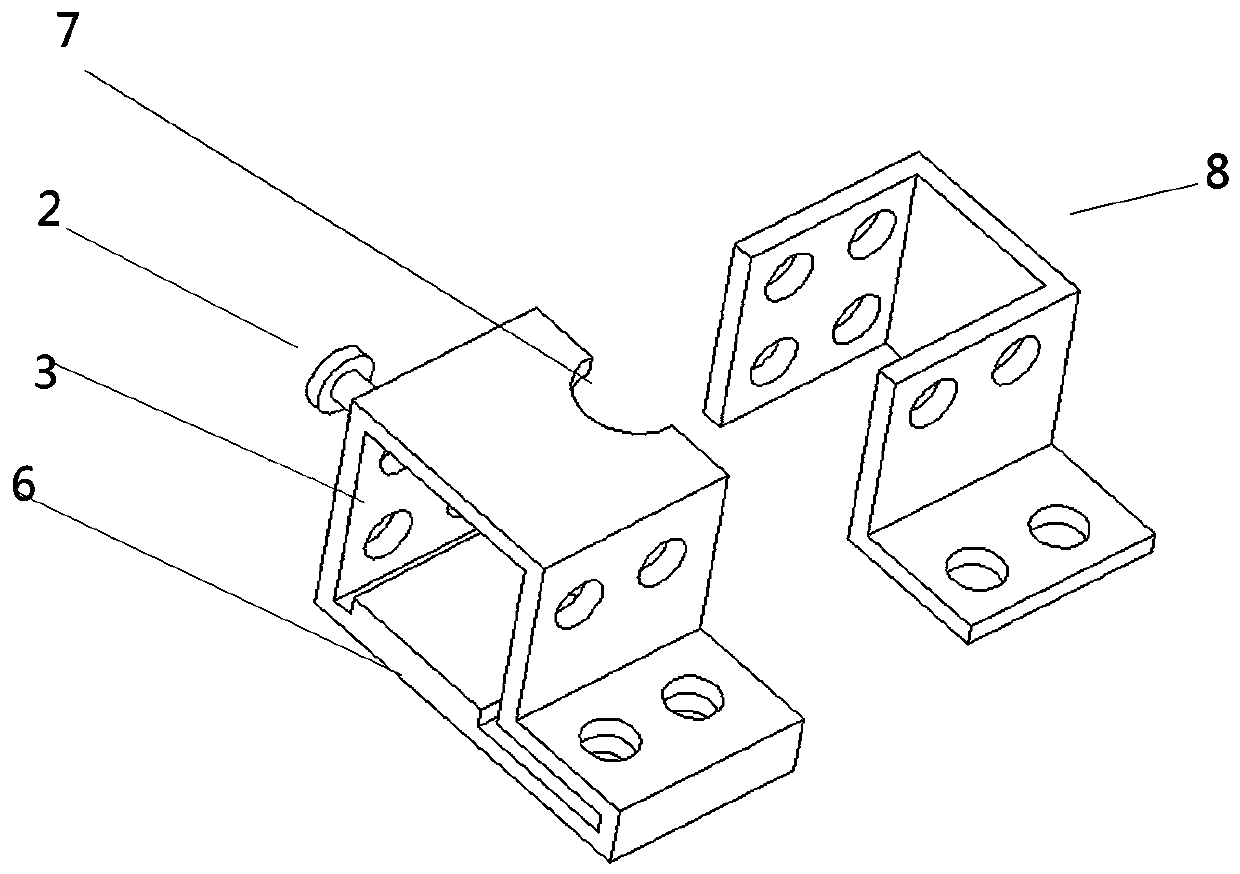

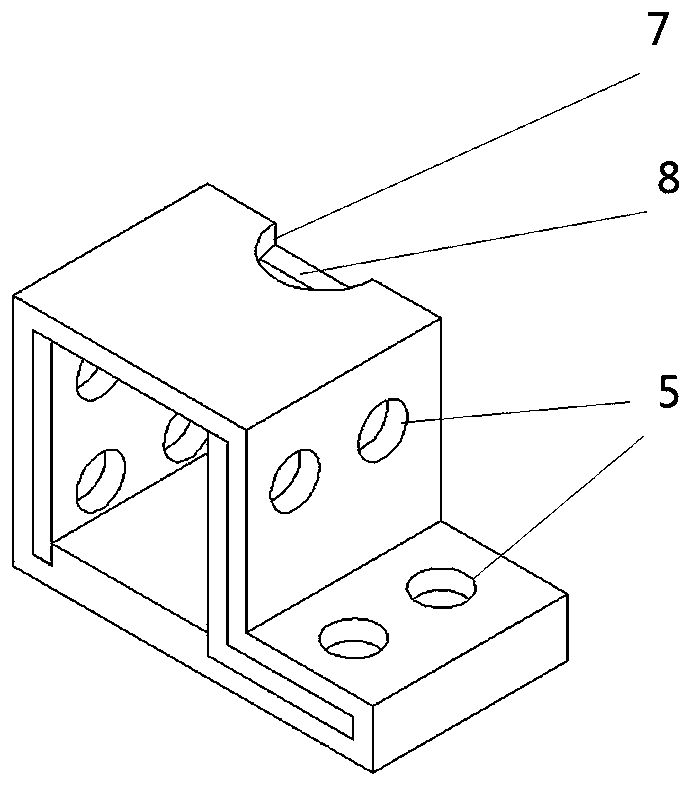

[0017] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0018] like Figure 1 to Figure 4 As shown, the foot code drilling jig of the present invention has an integral structure, and is formed with a bottom surface, a side surface, a top surface, a bottom surface, a side surface, and the top surface to encircle a cavity 3 for accommodating the foot code. There are guide holes on the wall to determine the drilling position of the feet, and there are fixing holes on the side walls. The bottom surface is provided with a support platform to prevent the deformation of the feet and a guide groove to save time and effort when pushing the parts into the jig. , the top surface, the bottom surface or both o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com