Pipe Bending Tooling

A bending and tooling technology, which is applied in the field of pipe fittings processing, can solve problems such as safety accidents, closed pipe bends, and equipment failure to operate normally, and achieve the effect of preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

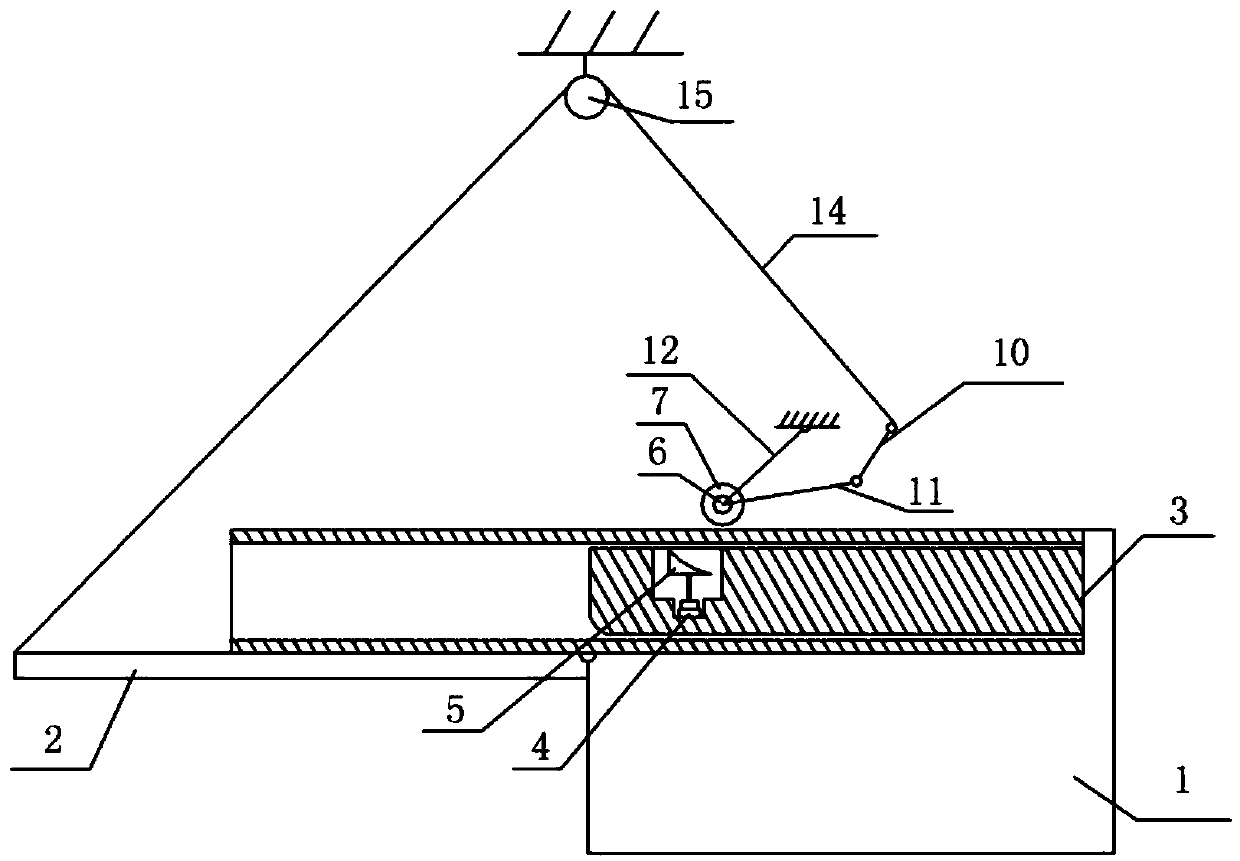

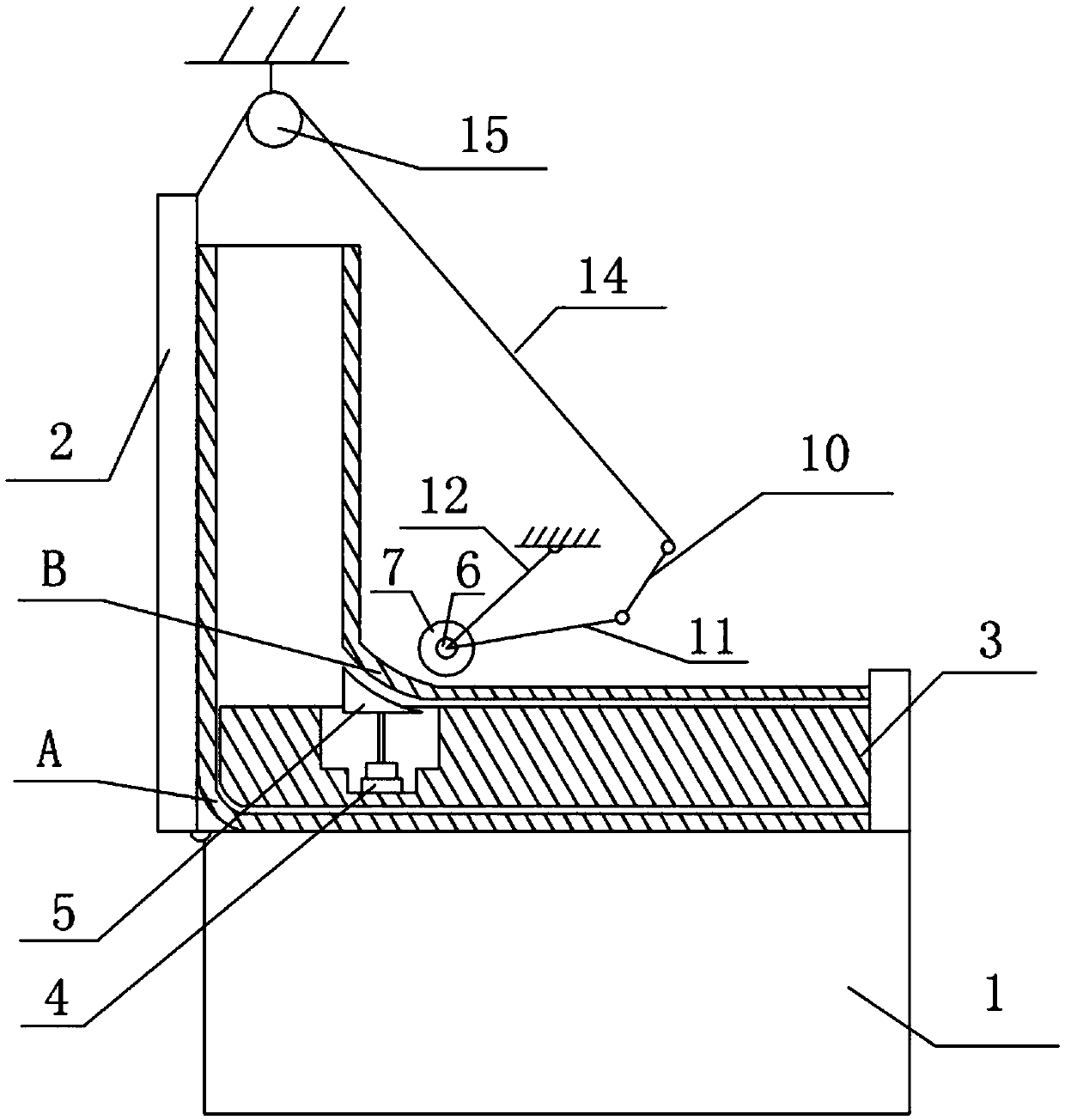

[0017] The reference signs in the accompanying drawings of the specification include: support table 1, bending plate 2, repair rod 3, cylinder 4, expansion block 5, rotating rod 6, round roller 7, servo motor 8, support rod 9, No. 1 connecting rod 10, No. 2 connecting rod 11, No. 3 connecting rod 12, pay-off stand 13, stay rope 14, pulley 15.

[0018] like figure 1 , 2 The pipe fitting bending tool shown includes a support platform 1, a bending plate 2, a cylindrical repair rod 3, an expansion mechanism, a transfer mechanism and a smooth transition mechanism. The right end of the bent plate 2 is hinged with the left end of the support platform 1 through a hinge, and the bent plate 2 is provided with a through groove. Repair rod 3 right ends are threadedly connected with support platform 1, repair rod 3 left corners are arc-shaped, the peripheral wall of repair rod 3 le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com