Environment-friendly dust removal device capable of automatically shaking off dust

A dust removal device and dust technology, applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of unfavorable surrounding environmental protection, reduced dust removal effect, limited filter area, etc., and achieve enhanced filtering and dust removal effects of equipment , Improve the effect of dust removal, improve the effect of dust removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

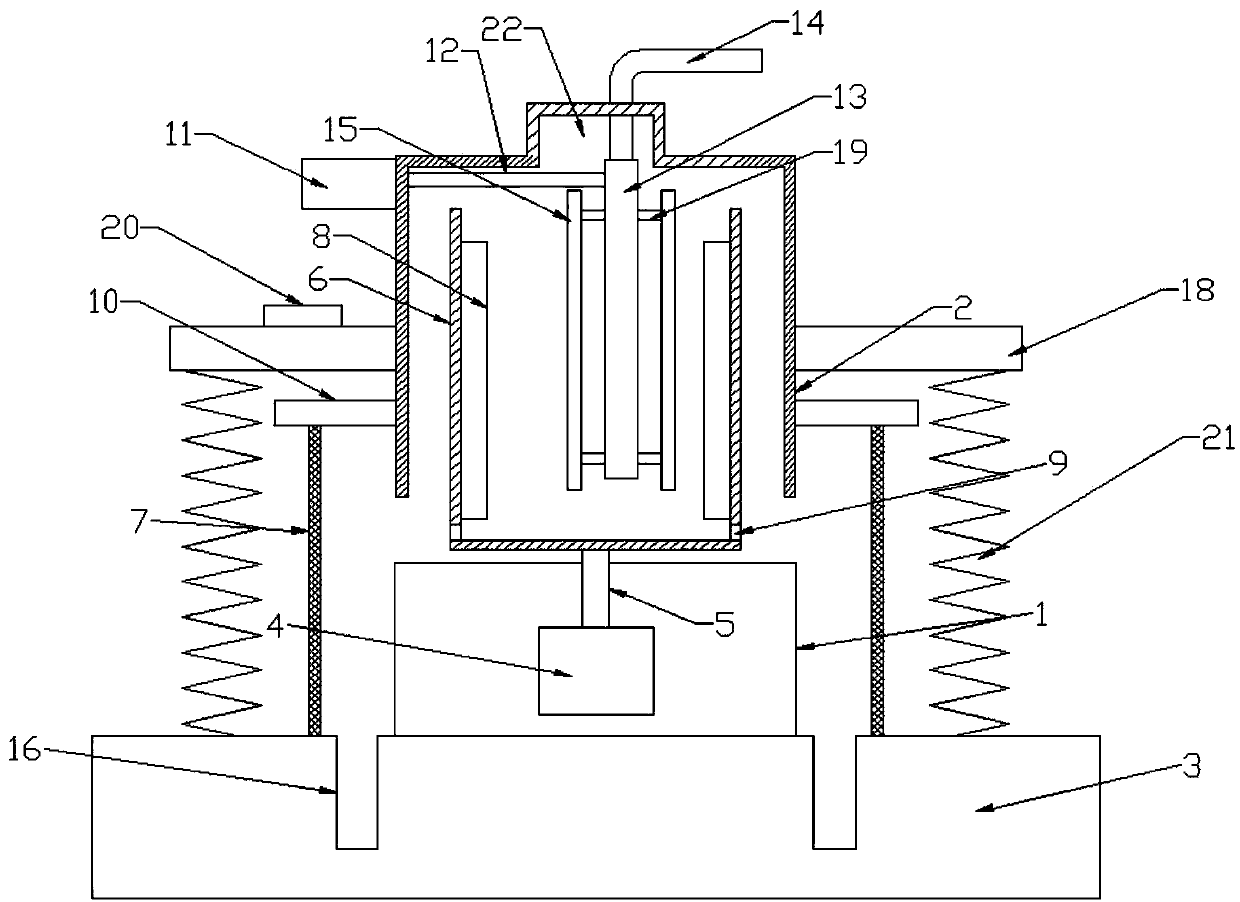

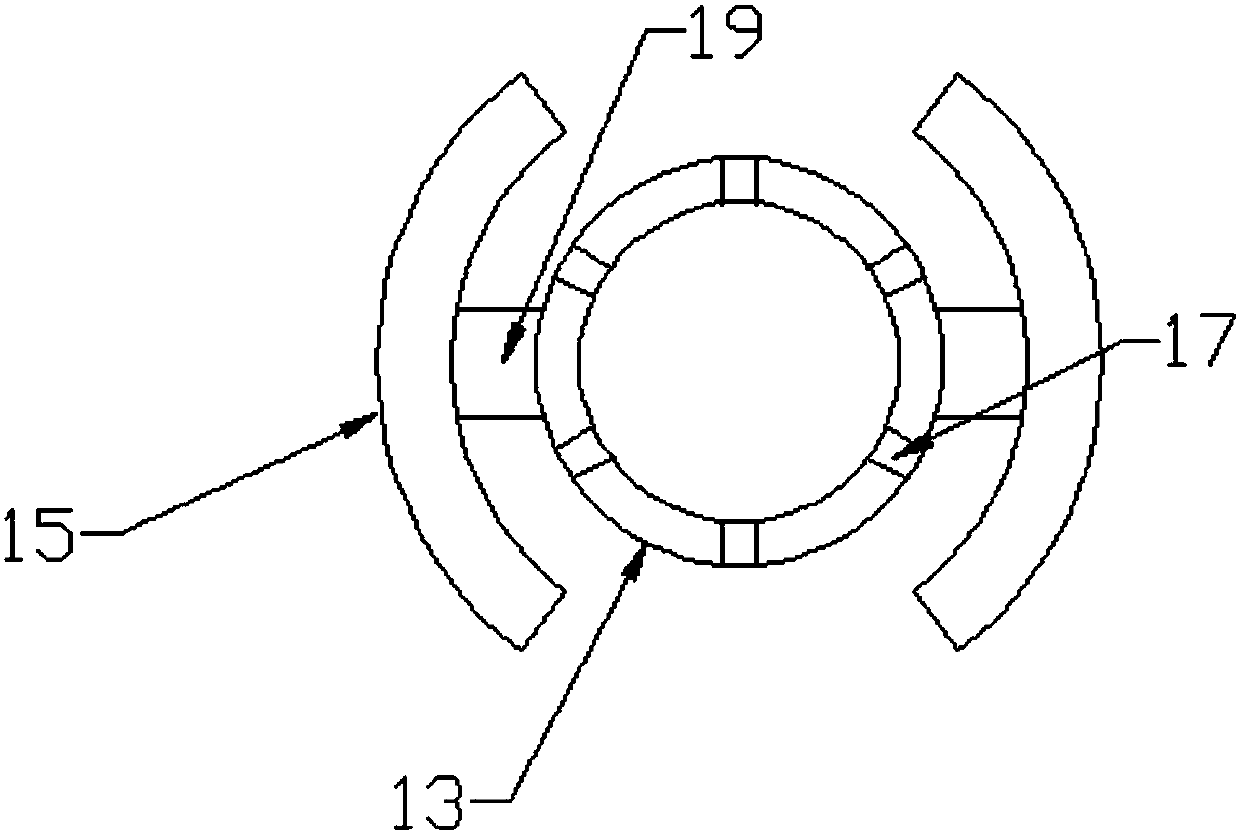

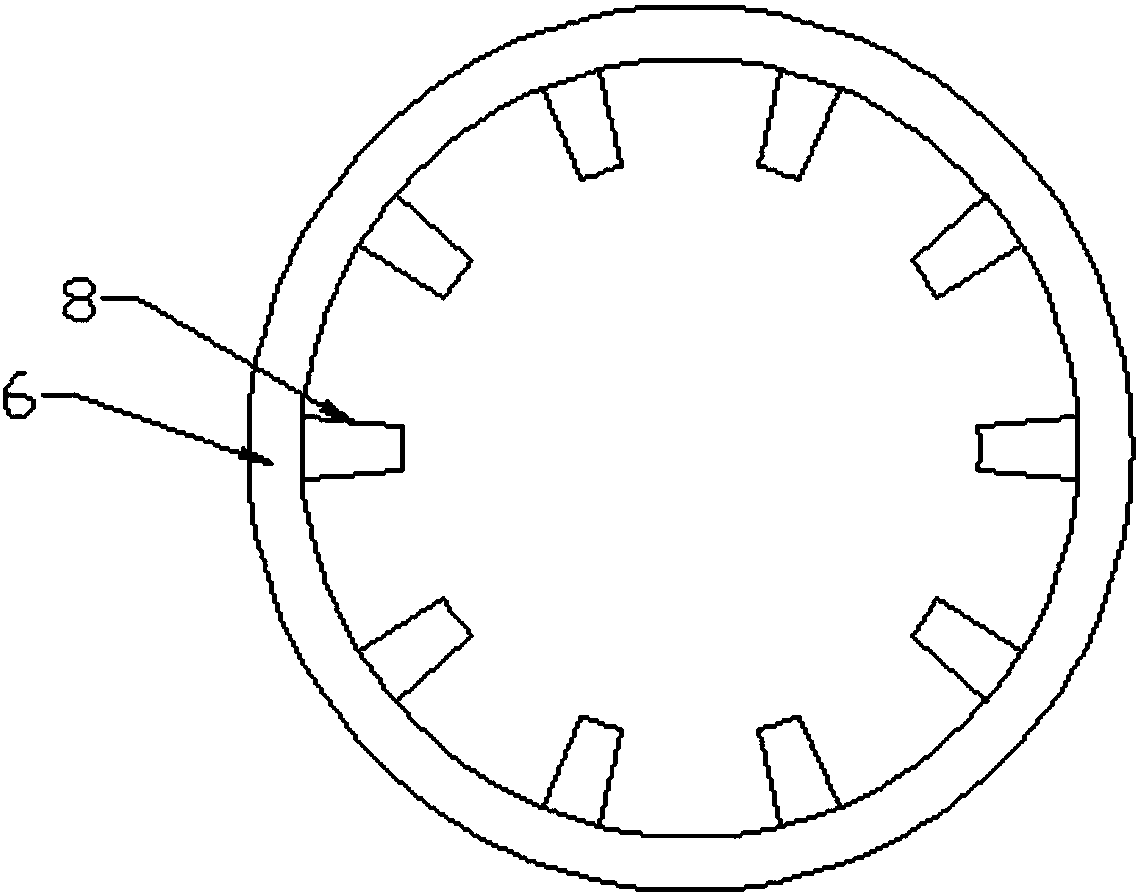

[0018] Please refer to the figure, in the embodiment of the present invention, an environmental protection dust removal device that automatically shakes off dust includes a base 1, a casing 2, a bottom plate 3, a motor 4 and a cylinder 11; the base 1 is fixedly installed with a vertical upward The motor 4 is fixedly connected with the rotating shaft 5 protruding from the base 1 on the output shaft of the motor 4, the upper end of the rotating shaft 5 is fixedly connected with the inner cylinder 6, and is located on the central axis of the inner cylinder 6, at the bottom of the inner cylinder 6 There are several air outlet holes 9 on the side wall, and the inner cylinder 6 rotates to blow out the internal air from the air outlet holes 9, and the air is evenly blown out to the surrounding; on the inner wall of the inner cylinder 6, there are several Stirring blades 8 are used to quickly diffuse the incoming air into the inner cylinder 6 , and stirring blades 8 are also arranged o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com