Sodium hypochlorite preparation system capable of being controlled and debugged remotely based on ARM single chip microcomputer and working method thereof

An ARM single-chip, sodium hypochlorite technology, applied in the field of sodium hypochlorite preparation, can solve the problems of important parameters without warning and alarm functions, difficult to stabilize and poor PID control accuracy, etc., to achieve the effect of rich interfaces and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

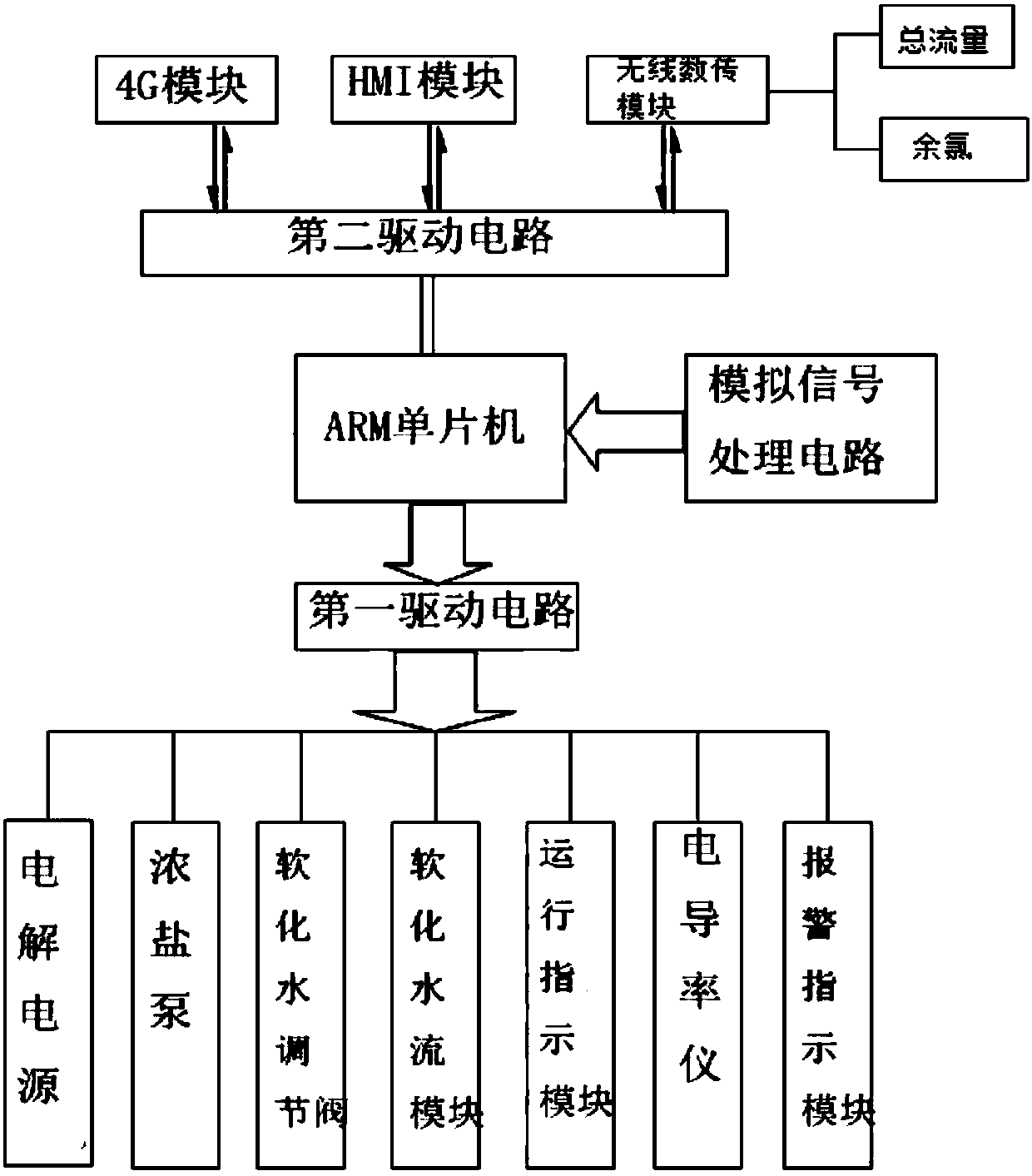

[0057] A sodium hypochlorite preparation system that can be remotely controlled and debugged based on an ARM microcontroller, such as figure 1 As shown, it includes ARM microcontroller, first drive circuit, second drive circuit, analog signal processing circuit, electrolysis power supply, concentrated salt pump, softened water regulating valve, softened water flow module, operation indicator module, conductivity meter, alarm indicator module, 4G module, HMI module, wireless data transmission module;

[0058] The ARM microcontroller is respectively connected to the first drive circuit, the second drive circuit, and the analog signal processing circuit;

[0059] The first drive circuit is respectively connected to the electrolysis power supply, the concentrated salt pump, the softened water regulating valve, the softened water flow module, the operation indicator module, the conductivity meter, and the alarm indicator module;

[0060] The second drive circuit is respectively co...

Embodiment 2

[0077] According to a kind of sodium hypochlorite preparation system that can be remotely controlled and debugged based on ARM single-chip microcomputer described in embodiment 1, the difference is that

[0078] The ARM microcontroller is a 32-bit ARM microcontroller of the STM32F407 series; as the brain of the entire control system, it realizes functions such as data collection, PID calculation, equipment control, and data storage;

[0079] The first drive circuit is a power drive circuit, including a 5V relay, a PC817 optocoupler isolator, and a C8050 triode;

[0080] The second drive circuit includes ADM2483 isolated 485 communication chip, sp3485 common 485 communication chip, sp3232 non-isolated 232 serial communication chip;

[0081] The model of the analog signal processing circuit is STM32F407; it is the built-in A / D interface;

[0082] The model of the electrolysis power supply is GGDF-300A / 25V; it adopts Huaxing Power Supply Company;

[0083] The model of the softe...

Embodiment 3

[0095] The operating method of the sodium hypochlorite preparation system that can be remotely controlled and debugged based on the ARM single-chip microcomputer described in embodiment 1 or 2 includes:

[0096] (1) Control dosage according to residual chlorine and total flow rate, judge the height of sodium hypochlorite liquid level at the same time, if liquid level is too low, enter step (2);

[0097] (2) Turn on the concentrated salt pump and softened water regulating valve to perform PID adjustment. When the brine concentration and softened water flow rate reach the set value, turn on the electrolysis power supply;

[0098] (3) In the process of electrolysis, the operation data is monitored in real time. When the ARM microcontroller detects the following situations, the alarm indicator module is mobilized to give an alarm: the operating frequency of the concentrated salt pump is high, the operating frequency of the concentrated salt pump is high, and the concentrated salt p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com