Static stiffness testing device for telescopic shock absorber superposition valve

A technology of testing device and superimposed valve, applied in the direction of measuring device, machine/structural component testing, elasticity testing, etc., can solve the problems of product design requirements, calculation efficiency and accuracy are difficult to meet, and achieve high reliability of results, The effect of high versatility and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

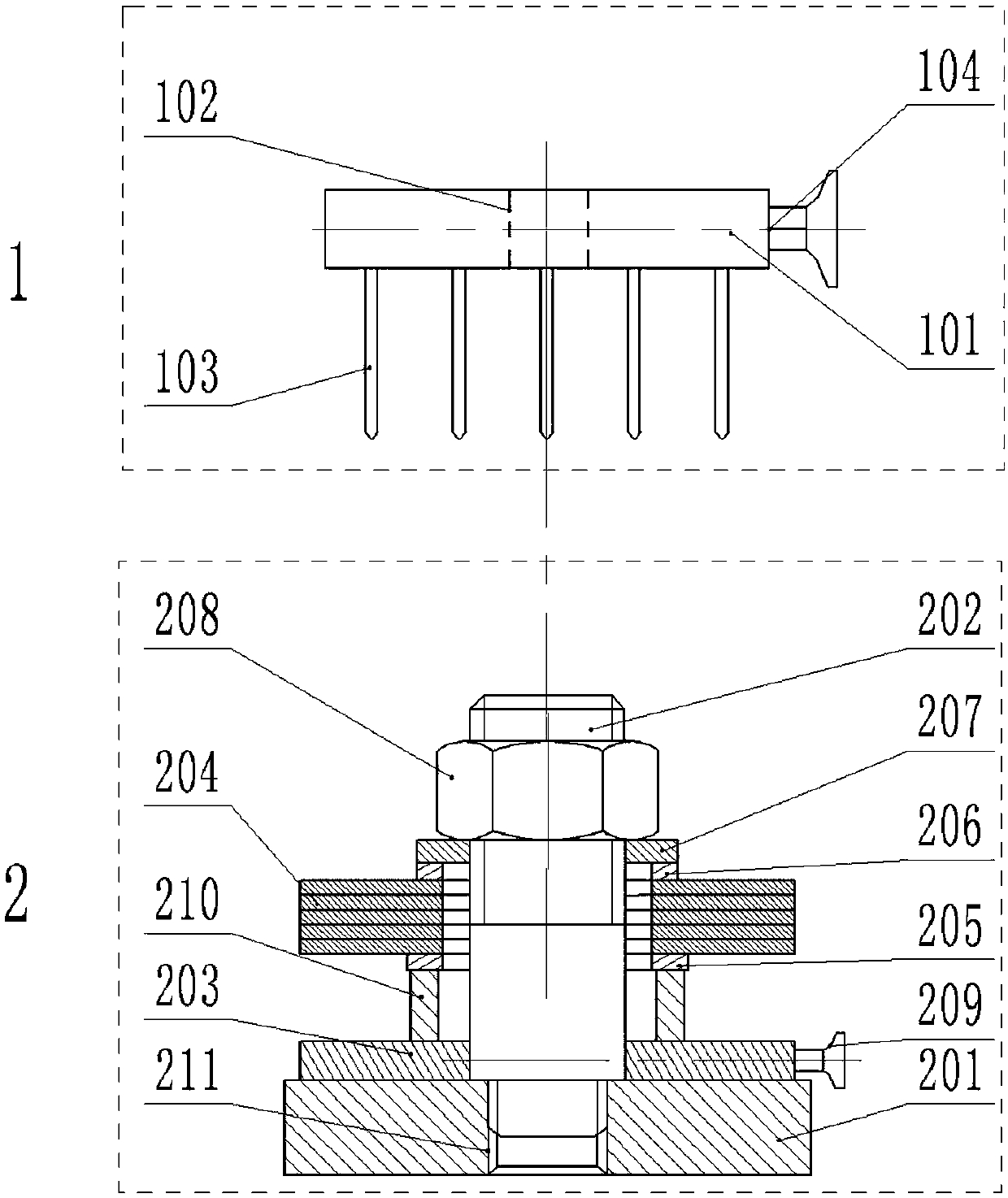

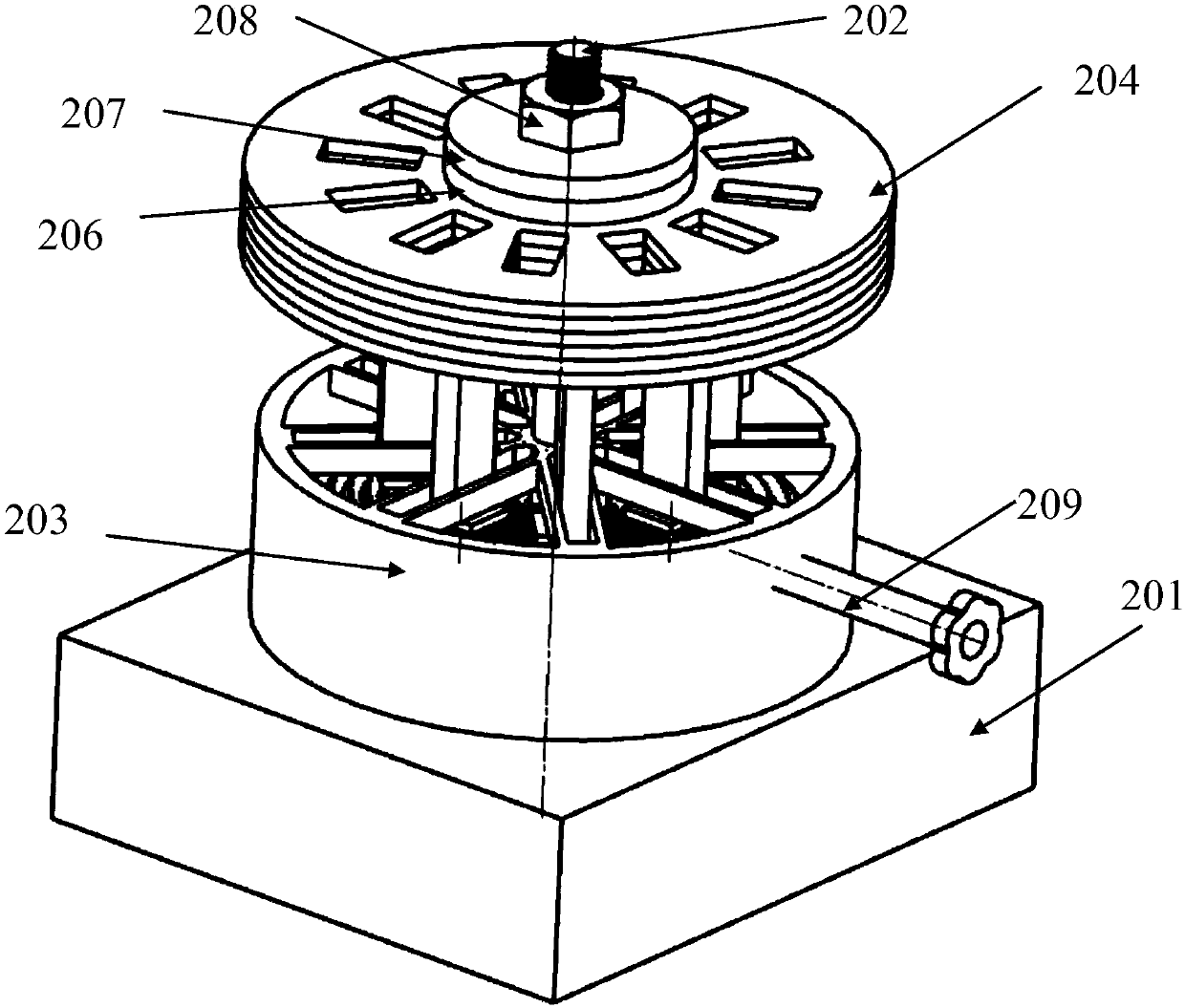

[0033] The structural cross-sectional view of a static stiffness test device for a stacked valve plate of a cylindrical shock absorber is shown in figure 1 As shown, the whole device includes upper fixture 1 and lower fixture 2.

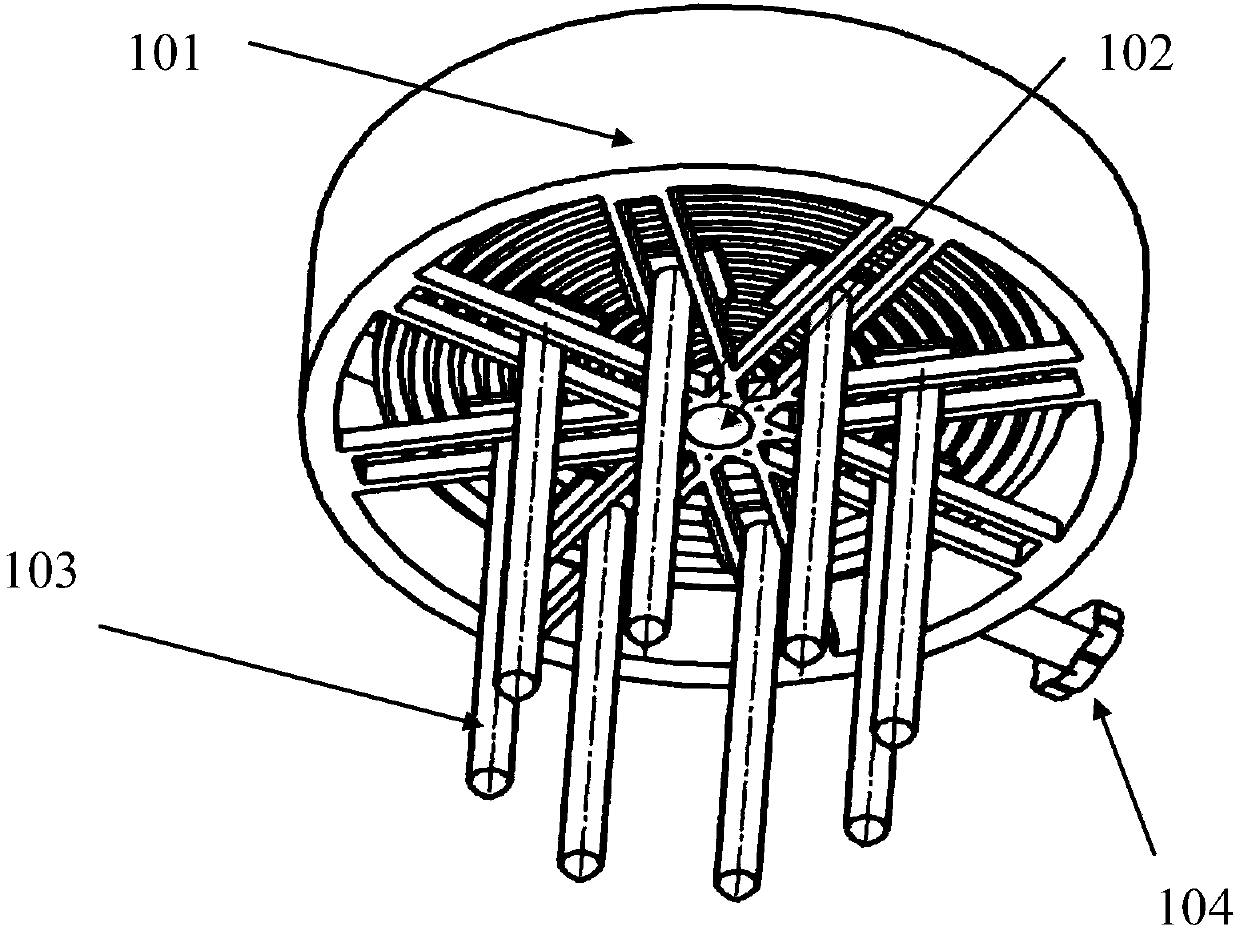

[0034] The three-dimensional diagram of the structure of the upper fixture 1 is as follows figure 2 As shown, it includes an adjustable upper clamp seat 101 , a threaded hole 102 , a force applying claw 103 , and an adjustment rod 104 .

[0035] In the adjustable upper clamp seat 101, the force applying claws 103 are embedded in eight chute 105, the movement of the force applying claws 103 in the chute 105 is adjusted through the worm gear mechanism, and the adjusting rod 104 is directly connected to the worm gear mechanism.

[0036] The three-dimensional diagram of the structure of the lower fixture 2 is as follows image 3 As shown, it includes a lower fixture seat 201, a positioning rod 202, an adjustable support seat 203, a superimposed valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com