Self-adaptive dynamic cold load regulation and control method for central air conditioning system

A central air-conditioning system, self-adaptive technology, applied in heating and ventilation control systems, heating and ventilation safety systems, applications, etc., can solve problems such as difficult operating conditions, lagging control effects, waste of electric energy, etc., to achieve power saving The effect of running and meeting the demand for on-demand cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

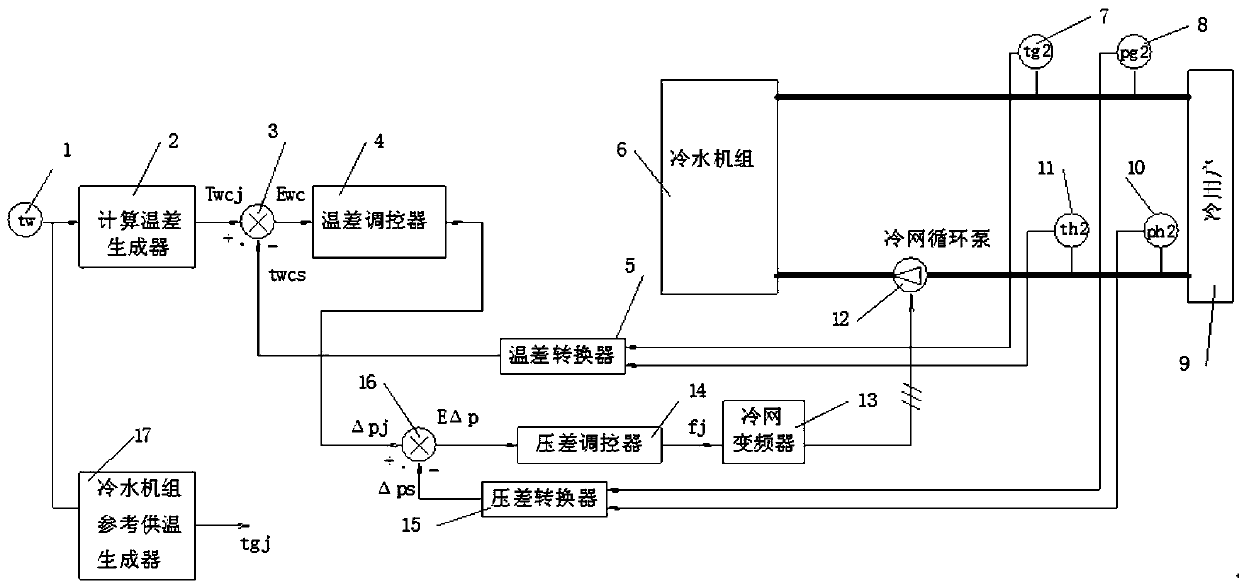

[0018] Below in conjunction with accompanying drawing and embodiment the method of the present invention will be further described,

[0019] An adaptive dynamic cooling load control method for a central air-conditioning system, comprising the following steps:

[0020] Step 1, obtain the outdoor temperature value through the outdoor temperature sensor, and calculate the temperature difference between supply and return water according to the outdoor temperature value;

[0021] Step 2, collect the actual supply and return water temperature difference of the cooling network through the temperature sensor;

[0022] Step 3: Compare the calculated supply and return water temperature difference with the actual supply and return water temperature difference, and output the calculated pressure difference required by the cooling network with the integral of the comparison error; set the dead zone value for the comparison error, when the calculated temperature difference minus the actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com