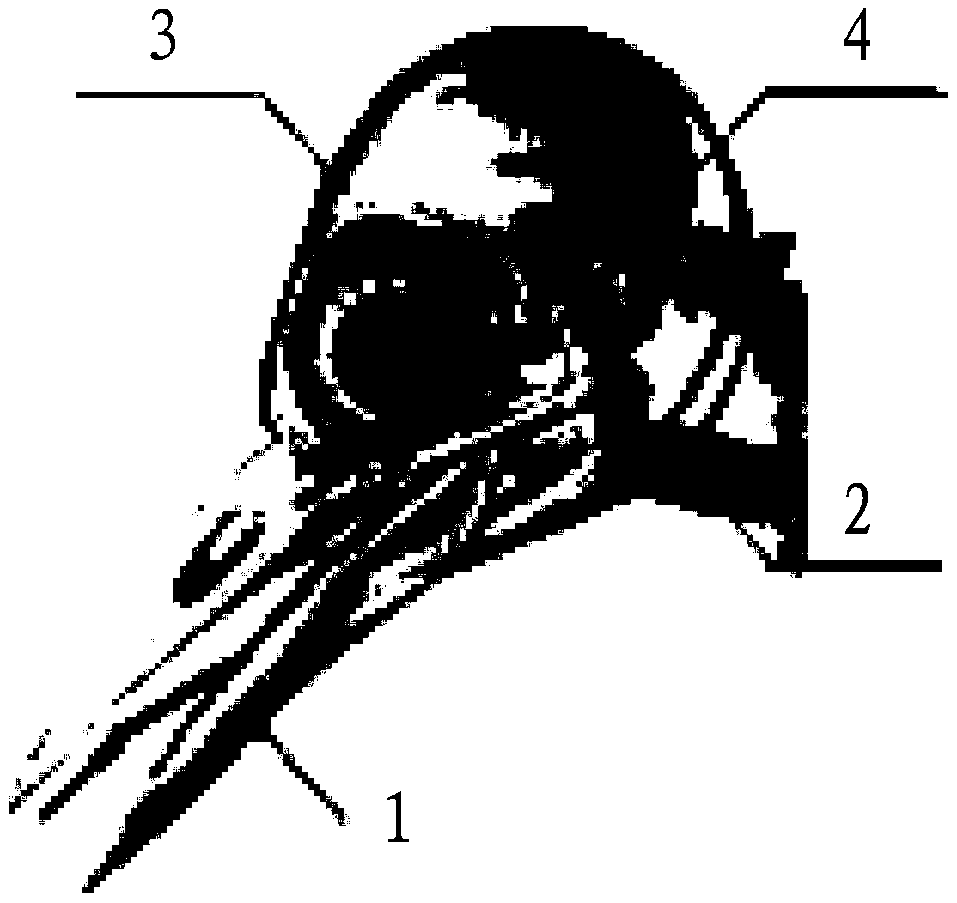

Woodpecker head-imitated impact-resistant structure and manufacturing method thereof

A production method and impact-resistant technology, applied in chemical instruments and methods, lamination auxiliary operations, other household appliances, etc., can solve problems such as damage, impact on service life, damage, etc., and achieve the effect of simple and convenient production process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

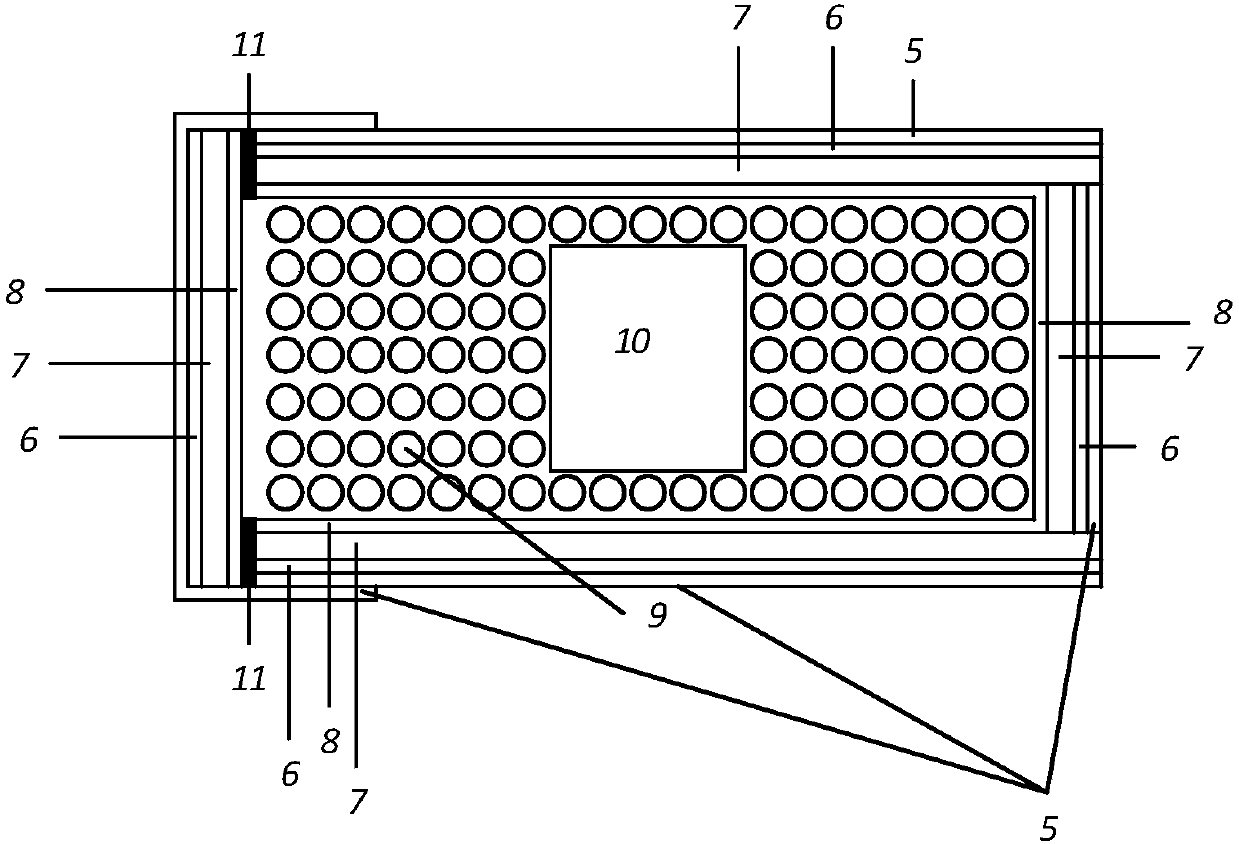

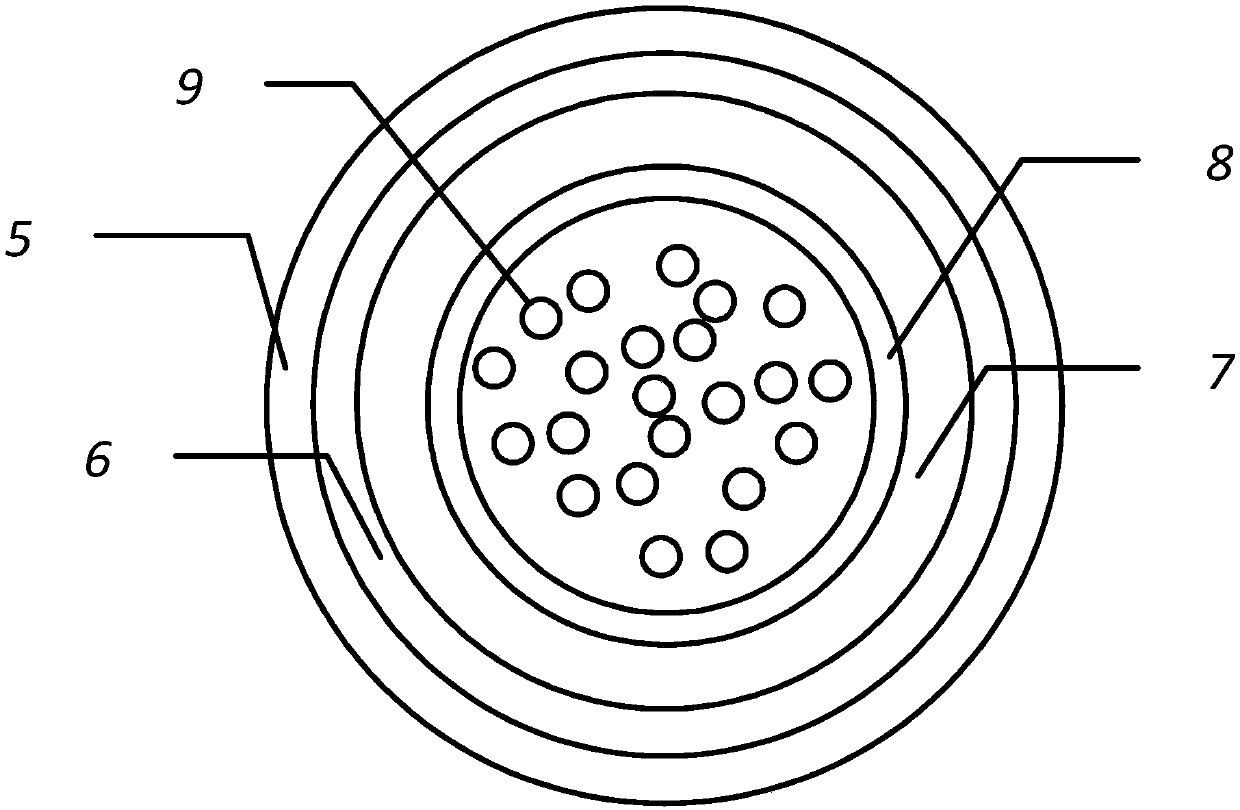

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1~4 As shown, the impact-resistant structure of the present invention includes an outer shell 5 and an inner shell 8, wherein the inner shell 8 is placed inside the outer shell 5 and arranged coaxially, and between the outer shell 5 and the inner shell 8, cancellous bone reducing vibrating layer 7 and damping layer 6. A protected precision electronic component or device 10 is placed inside the inner shell 8 , and resin beads 9 are filled in the inner shell 8 . Both the outer shell 5 and the inner shell 8 are hollow cylinders with one end open, and a damping layer 6 and a cancellous bone damping layer 7 are provided between the side surfaces and bottom surfaces of the outer shell 5 and the inner shell 8 . Bonding is performed between the outer shell 5 and the damping layer 6 , between the damping layer 6 and the cancellous bone damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com