Clamp for relieving locker locking state

A locker and fixture technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of damage to the slideway of the locker, easy damage to the surface of the locker and the circuit board, and the left and right shaking of the circuit board, so as to improve Quality and production efficiency, simplification of commissioning and maintenance work, and the effect of ensuring the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

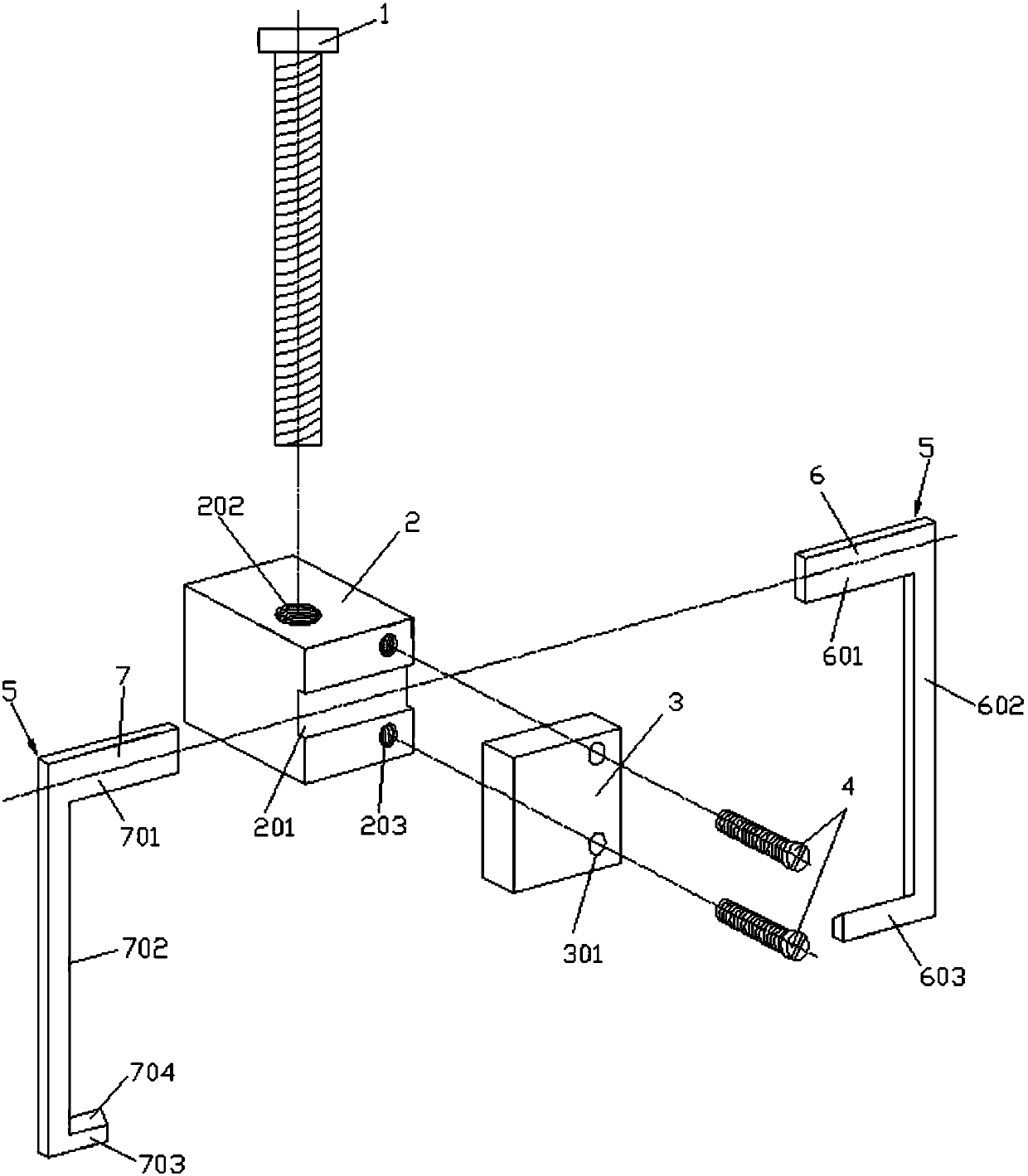

[0022] Attached below Figure 1-6 Embodiments of the present invention are described.

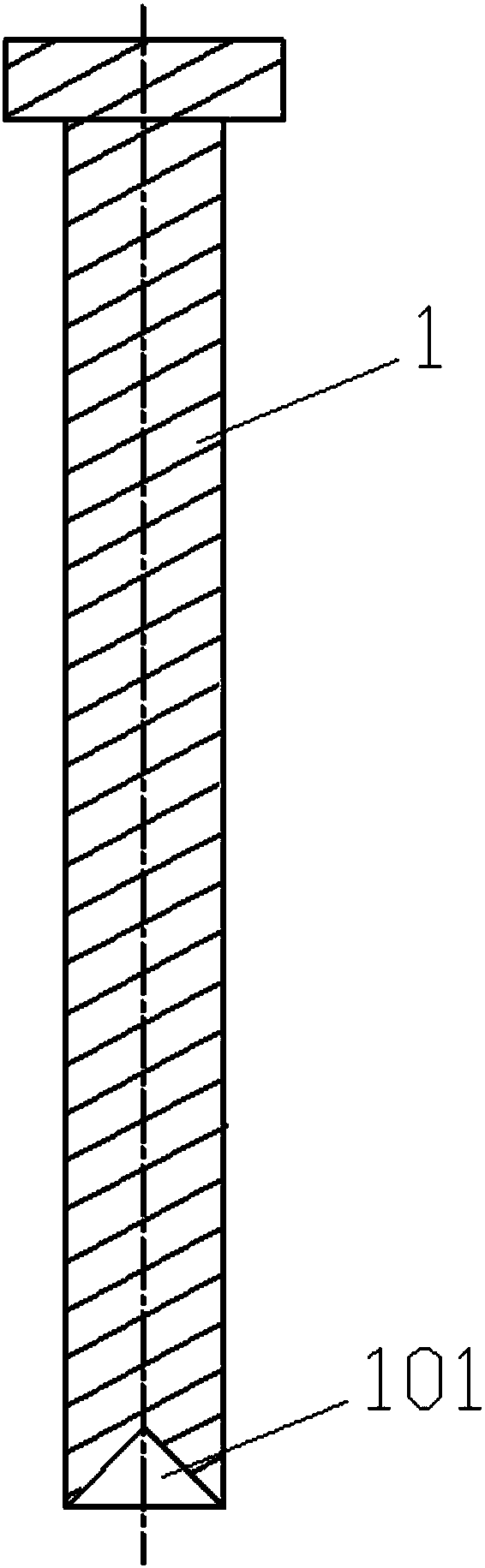

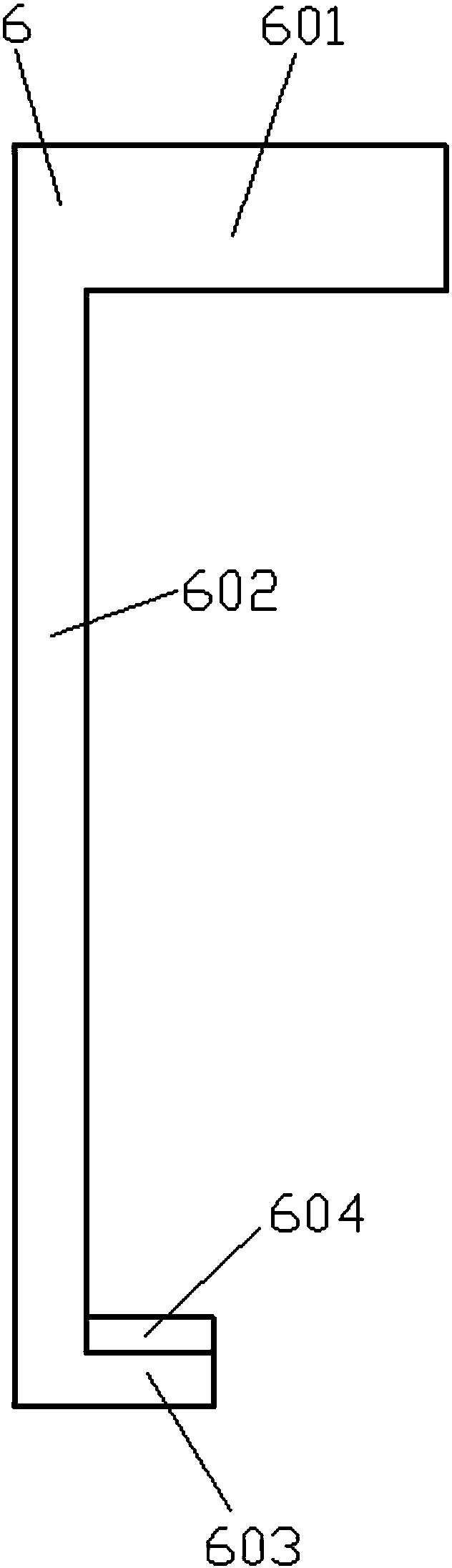

[0023] A jig for releasing the locking state of the locking device, such as figure 1 As shown, it includes a clamp body 2, a lifting screw 1, a baffle plate 3 and a hook plate 5. The vertical thread in the middle of the clamp body 2 is screwed with a lifting screw 1, and the lower end of the lifting screw 1 passes through the clamp body 2 and is used for tightening. Position at the top of the locker bolt head 11. Preferably, the specification of the lifting screw 1 is M4×35, and the clamp body 2 is provided with a threaded hole I 202 screwed with the lifting screw 1 . Specifically, a positioning groove 101 adapted to the top end of the locking device bolt head 11 is formed on the lower end surface of the lifting screw 1, as figure 2 As shown, when the clamp is used to release the locked state of the locker, the positioning groove 101 of the lifting screw 1 is pushed against the bolt he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com