A small flue gas treatment device

A flue gas treatment and flue technology, applied in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of labor-intensive, short maintenance cycle, and financial-intensive, prolong replacement and renewal cycle, and improve purification efficiency. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

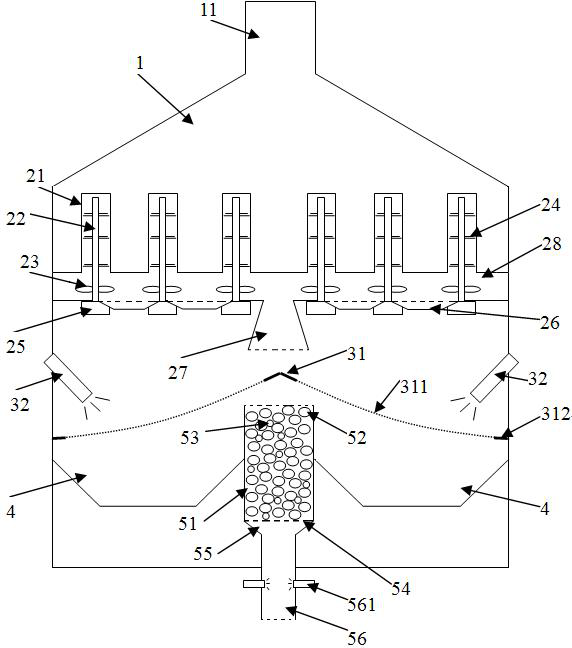

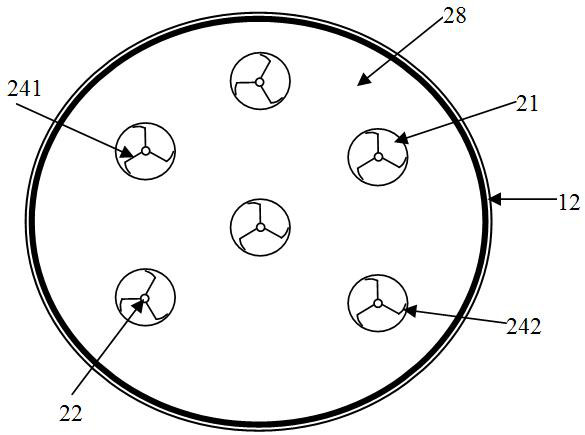

[0031] Such as Figure 1-2 Shown: A small flue gas treatment device, including dust removal upper chamber, dust removal lower chamber, bag dust removal parts, mud removal parts and purification pipe parts.

[0032] The upper dedusting chamber is a hollow circular frustum structure as a whole, the top surface of the conical frustum is provided with a clean flue gas outlet, and the bottom surface of the conical frustum is connected to the lower dedusting chamber; Bag dust removal parts, mud removal parts, mud collection tanks and purification pipe parts.

[0033]The bag dust removal part is arranged on the uppermost part of the dust removal lower chamber, including a cloth bag, a rotating rod, a propeller blade, a dust removal rod, a motor, a dust collection tank, a dust removal inlet and a main dust removal pipe; the main dust removal pipe runs across the lower dust removal chamber , and it is sealed with the side wall of the dust removal lower chamber, and the dust removal lo...

Embodiment 2

[0047] A small flue gas treatment device comprises a dust removal upper chamber, a dust removal lower chamber, a bag dust removal unit, a mud removal unit and a purification pipe unit.

[0048] The upper dedusting chamber is a hollow circular frustum structure as a whole, the top surface of the conical frustum is provided with a clean flue gas outlet, and the bottom surface of the conical frustum is connected to the lower dedusting chamber; Bag dust removal parts, mud removal parts, mud collection tanks and purification pipe parts.

[0049] The bag dust removal part is arranged on the uppermost part of the dust removal lower chamber, including a cloth bag, a rotating rod, a propeller blade, a dust removal rod, a motor, a dust collection tank, a dust removal inlet and a main dust removal pipe; the main dust removal pipe runs across the lower dust removal chamber , and it is sealed with the side wall of the dust removal lower chamber, and the dust removal lower chamber is divide...

Embodiment 3

[0063] A small flue gas treatment device comprises a dust removal upper chamber, a dust removal lower chamber, a bag dust removal unit, a mud removal unit and a purification pipe unit.

[0064] The upper dedusting chamber is a hollow circular frustum structure as a whole, the top surface of the conical frustum is provided with a clean flue gas outlet, and the bottom surface of the conical frustum is connected to the lower dedusting chamber; Bag dust removal parts, mud removal parts, mud collection tanks and purification pipe parts.

[0065] The bag dust removal part is arranged on the uppermost part of the dust removal lower chamber, including a cloth bag, a rotating rod, a propeller blade, a dust removal rod, a motor, a dust collection tank, a dust removal inlet and a main dust removal pipe; the main dust removal pipe runs across the lower dust removal chamber , and it is sealed with the side wall of the dust removal lower chamber, and the dust removal lower chamber is divide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com