A kind of preparation method and application of antibacterial coating on dental implant surface

A dental implant and surface antibacterial technology, applied in coatings, prostheses, medical science, etc., can solve the problems of easy falling off, inability to sterilize for a long time, high cost of antibacterial peptides, etc., and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

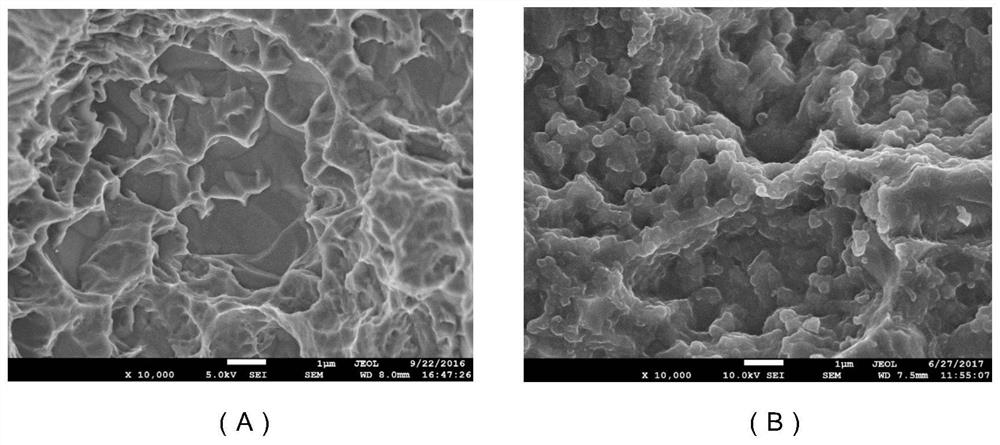

Image

Examples

Embodiment 1

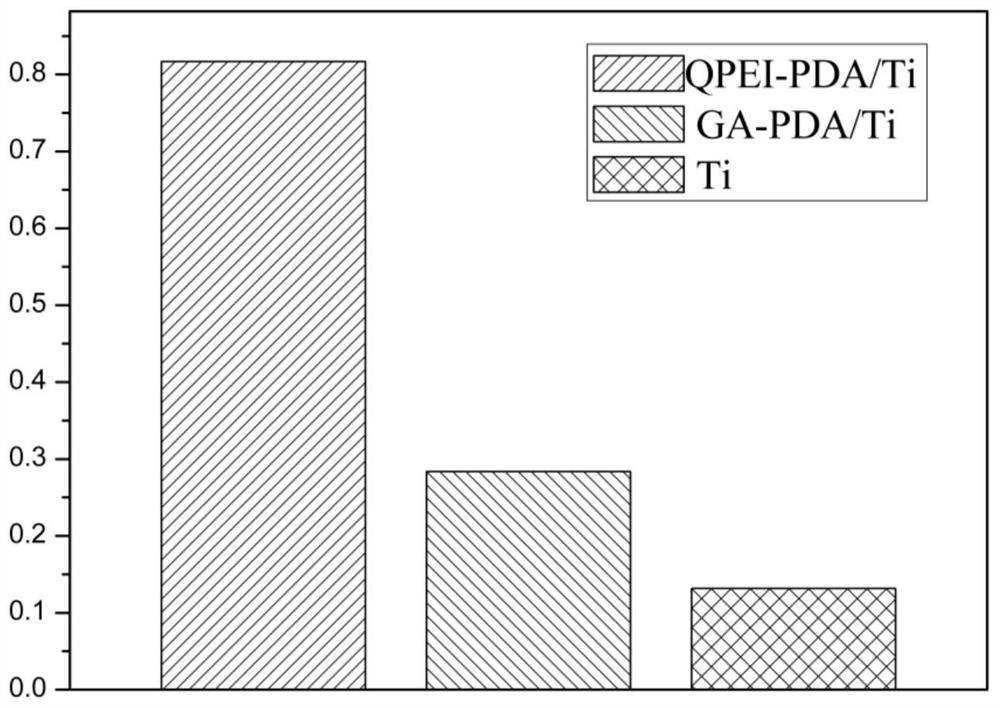

[0020] Prepare a 1mg / mL dopamine aqueous solution, put the treated metal titanium disk into the above solution, react for 2 hours, and the reaction temperature is 30°C, take out the titanium piece, clean it and dry it. Add BiBB to DMSO at a concentration of 4.3×10 -4 mol / mL, add the above titanium sheet. Dissolve glycidyl methacrylate in ethanol at a concentration of 4.3×10 -2 mol / mL, then add the above-mentioned titanium sheet and add CuBr 8mg / mL, PMDETA 20uL / mL, react for 1h, take out the titanium sheet, wash and dry. Dissolve 2 mL of ethylenediamine in 4 mL of organic solvent DMSO, add the titanium sheet obtained above and react for 2 h, prepare a 2.5% glutaraldehyde solution, and put the above titanium sheet. Prepare 5 mg / mL of quaternized PEI 600 solution, and put in the above-mentioned titanium sheet. Escherichia coli was used for antibacterial experiments, and the bacterial solution was 10 6 CFU, co-cultivate the titanium sheet and the bacterial solution at 37°C for...

Embodiment 2

[0022] Prepare 2mg / mL dopamine aqueous solution, put the metallic titanium disk into the above solution, react for 3h, the reaction temperature is 30°C, take out the titanium disk, clean it and dry it. Add BiBB to DMSO at a concentration of 4.3×10 -4 mol / mL, add the above titanium sheet. Dissolve glycidyl methacrylate in ethanol 4.3×10 -2 mol / mL, then add the above-mentioned titanium sheet, add CuBr 8mg / mL, PMDETA 20uL / mL, react for 2h, take out the titanium sheet, wash and dry. Dissolve 2 mL of ethylenediamine in 4 mL of organic solvent DMSO, add the titanium sheet obtained above and react for 2 h, prepare a 3% glutaraldehyde solution, and put the above titanium sheet. Prepare 6 mg / mL of quaternized PEI 600 solution, and put in the above-mentioned titanium sheet. Escherichia coli was used for antibacterial experiments, and the bacterial solution was 10 6 CFU, co-cultivate the titanium sheet and the bacterial solution at 37°C for 6h. The experimental group is the titanium...

Embodiment 3

[0024] Prepare 3mg / mL dopamine aqueous solution, put metal titanium disk into the above solution, react for 4h, reaction temperature is 30°C, take out the titanium piece, wash and dry. Add BiBB to DMSO at a concentration of 4.3×10 -4 mol / mL, add the above titanium sheet. Dissolve glycidyl methacrylate in ethanol 4.3×10 -2 After mol / mL, add the above-mentioned titanium sheet, add CuBr 8mg / mL, PMDETA 20uL / mL, react for 3h, take out the titanium sheet, wash and dry. Dissolve 2mL of ethylenediamine in 4mL of organic solvent DMSO, add the titanium sheet obtained above and react for 2h, prepare a 3.5% glutaraldehyde solution, and put the above titanium sheet. Prepare 7 mg / mL of quaternized PEI 600 solution, and put in the above-mentioned titanium sheet. Escherichia coli was used for antibacterial experiments, and the bacterial solution was 10 6 CFU, co-cultivate the titanium sheet and the bacterial solution at 37°C for 6h. The experimental group is the titanium sheet modified w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com