Limiting structure of detachable lifting boiler

A technology of limit structure and clamping structure, which is applied in the field of limit pieces and limit structures of detachable lift boilers, can solve the problem of inability to fix the height of the screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

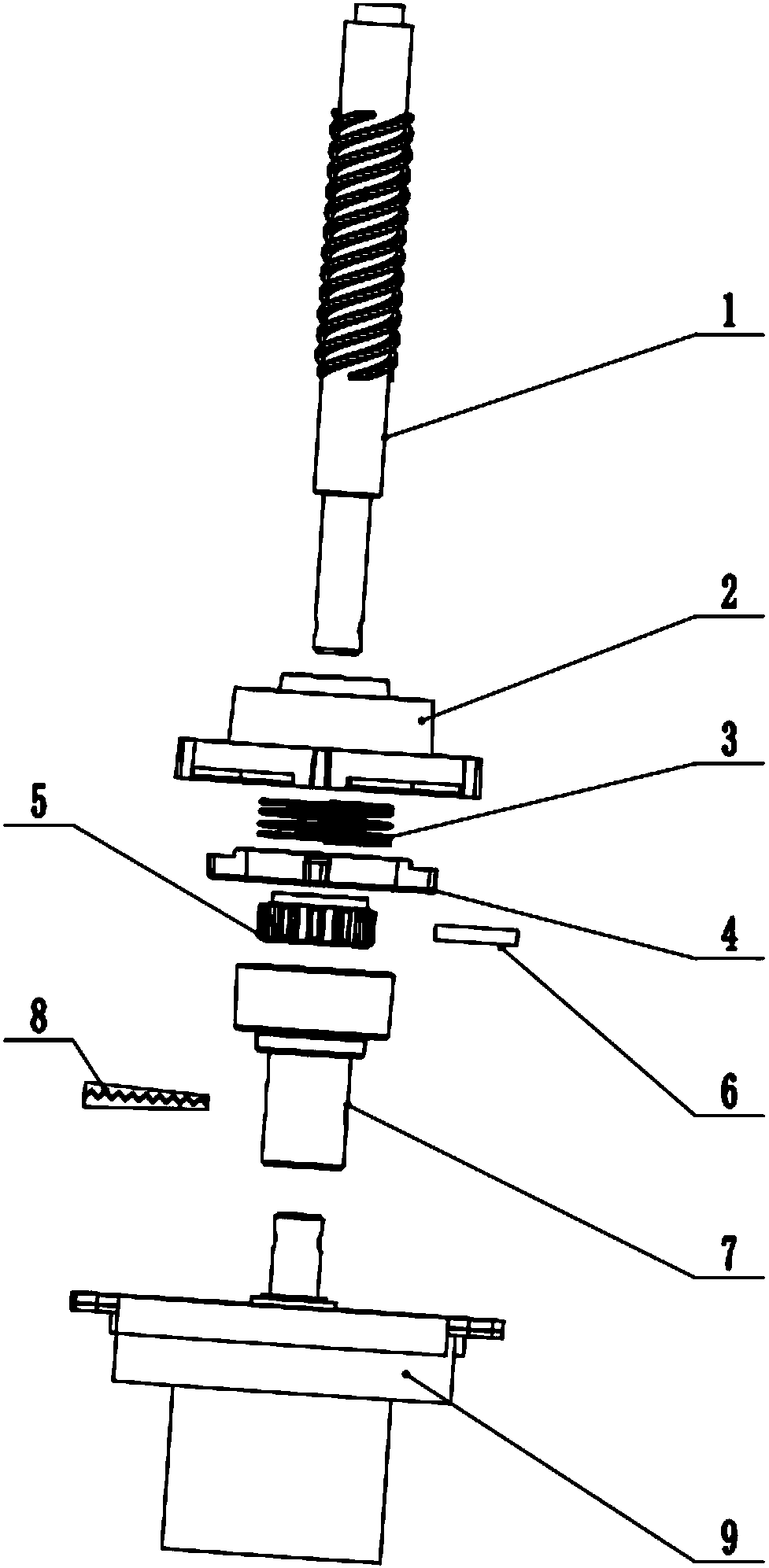

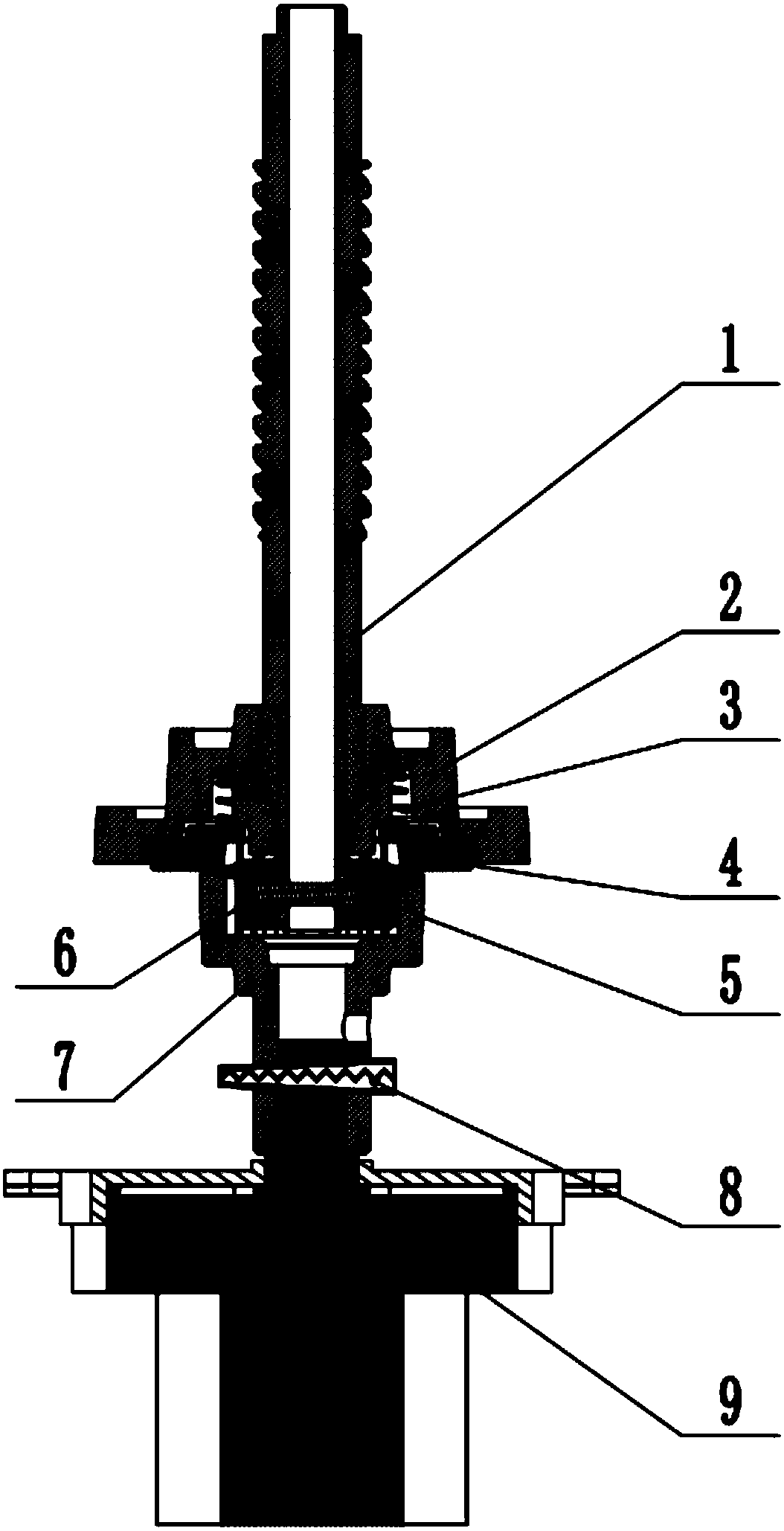

[0024] refer to figure 1 , 2 , 5 In this embodiment, it includes a lock nut 2, an elastic member 3, a rotation stop member 4, a rotating gear 5, a motor connector 7, and a motor 9, and its structural characteristics are: the motor connector 7 has a The connecting part of the connecting part and the interlocking part with the rotating gear 5 are mutually nested. The motor extends upwards from the motor shaft, and the motor shaft is connected to the motor connecting part 7 through the bolt 8. The middle part of the lock nut 2 is provided with a basic accommodation elastic part 3 and a stopper. In the section of the rotating part 4, the elastic part 3 supports the anti-rotating part 4, when the elastic part 3 or the magnetic part 10 is compressed, the anti-rotating part 4 is embedded in the lock nut 2, and when the elastic part 3 is in a normal state, the anti-rotating part 4 is higher than the locking nut 2 And mesh with the rotating gear 5; one end of the screw 1 passes throug...

specific Embodiment 2

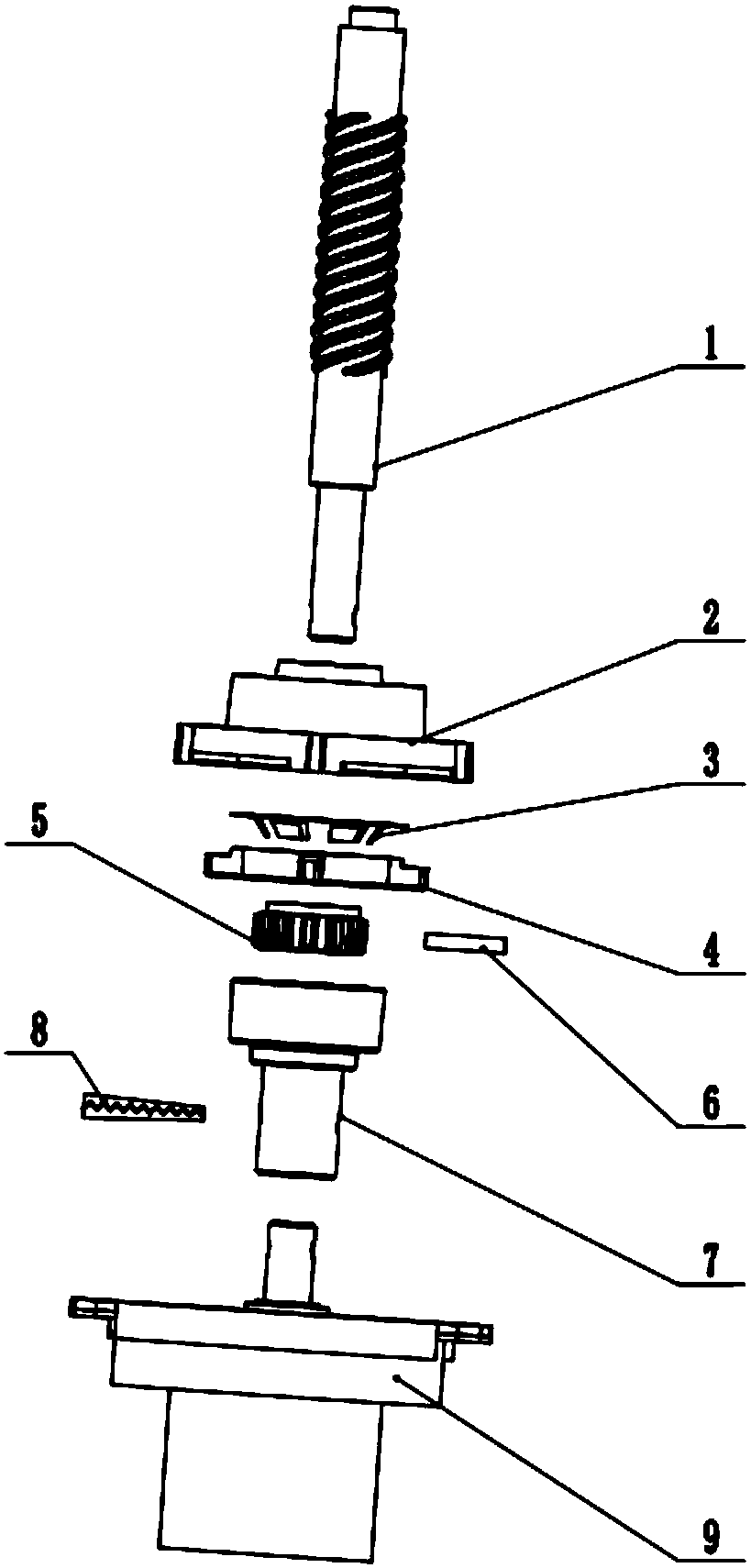

[0027] refer to image 3 In this embodiment, the elastic member 3 is an elastic plastic ring; other parts are consistent with the specific embodiment 1.

specific Embodiment 3

[0028] refer to Figure 4 Compared with the specific embodiment 1, in this embodiment, the elastic part 3 is replaced by a magnetic part 10, and the magnetic part 10 is respectively arranged in the lock nut 2 and on the anti-rotation part 4, and inside the lock nut 2 and on the anti-rotation part 4 The magnetic parts 10 on the top are oppositely arranged for the magnetic poles of the same name.

[0029] refer to Figures 1 to 4 In the above three specific embodiments, the motor connector 7 has a connecting portion for plug connection and a linkage portion that is nested with the rotating gear. The motor 9 protrudes upwards from the motor shaft, and the motor shaft is connected with the motor 9 connector through a bolt. The motor connector 7 and the rotating gear are cooperatingly socketed to realize the indirect connection between the motor 9 and the screw rod 1, and realize the detachability between the lifting hot pot motor 9 and the lifting assembly.

[0030] The two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com