Electromagnetically actuated drives for linear motion

An electromagnetic drive, electromagnet technology, applied in the direction of the electromagnet with armature, valve operation/release device, electromagnet, etc., can solve the problem of large size, can not provide high-voltage system, etc., to achieve the effect of strong damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

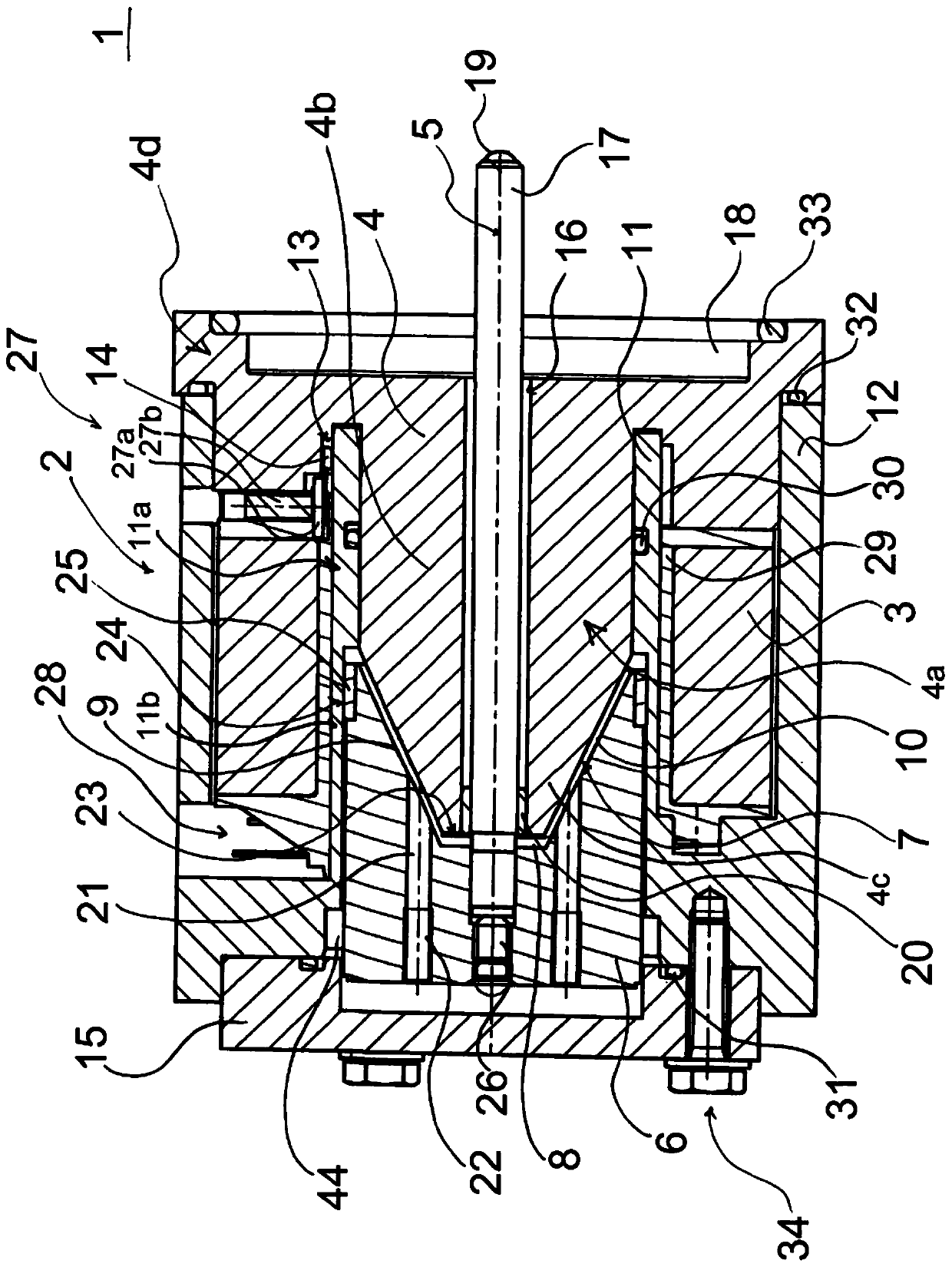

[0039] figure 1 A sectional view of an electromagnetic drive 1 according to the invention is shown and has an electromagnet 2 with a coil 3 , a core 4 and an armature 6 . Between the core 4 and the armature 6 an air gap 7 is formed, which is defined by the surface of the frusto-conical or conical core 4 and the diametrically oppositely shaped surface of the armature 6 .

[0040] The housing 12 of the electromagnetic drive 1 is rectangular, wherein the housing 12 has a hollow cylindrical rod 11 inside. The rod 11 and the housing 12 are integrally formed, especially integrally rotatable. Furthermore, the rod 11 is open to both the upper side as well as the lower side of the housing 12 and thus forms a channel between the two opposite sides.

[0041] The core 4 has a rotationally symmetrical body 4 a relative to the axis of symmetry 5 with a cylinder 4 b and a frustum 4 c inserted into the cylindrical interior of the rod 11 . In order to mount or fix the core 4 at a specific p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com