Tapping device using vacuum and tapping control method

A control method, a vacuum technology, applied in the manufacture of converters, etc., can solve the problem that the siphon effect is not easy to realize, and achieve the effects of shortening the power off time, improving productivity, and preventing the mixing of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the embodiments of the present invention can be modified into various forms, and the scope of the present invention is not limited to the embodiments described below. In order to illustrate more clearly, the shapes and sizes of elements in the drawings may be shown enlarged, and elements denoted by the same reference numerals in the drawings refer to the same elements.

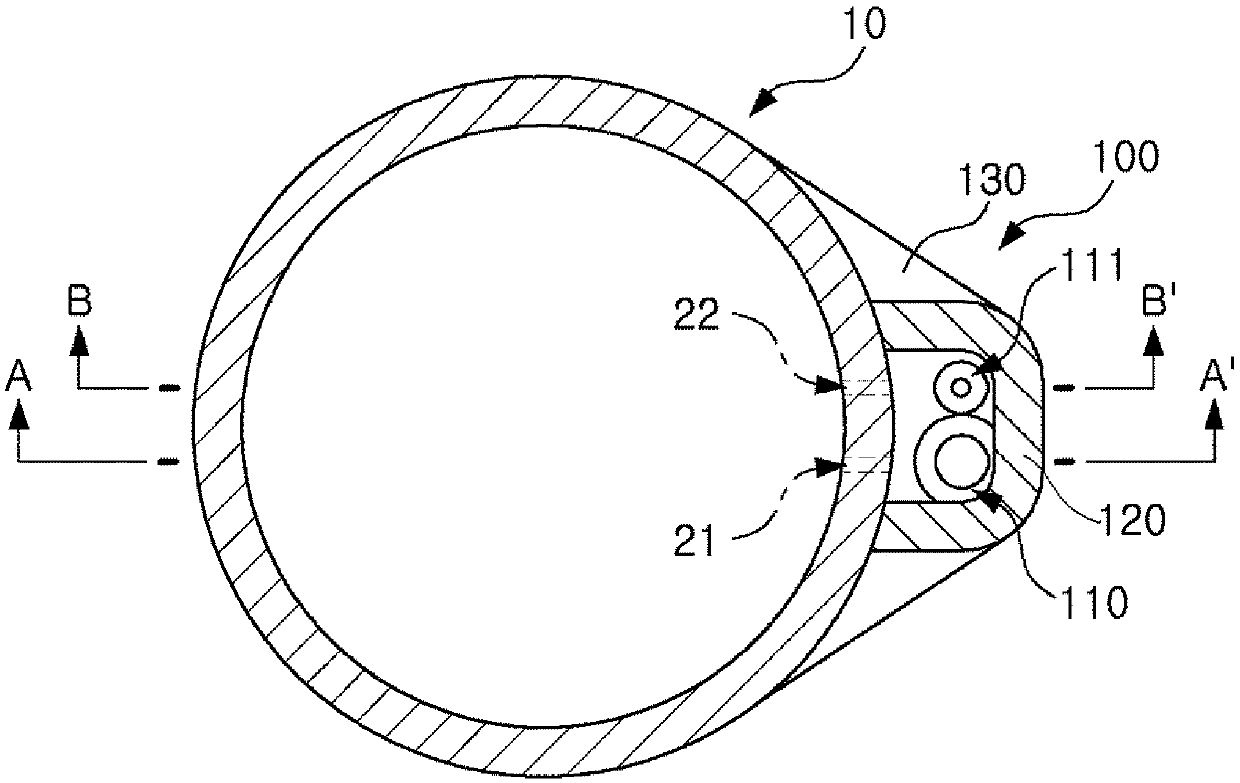

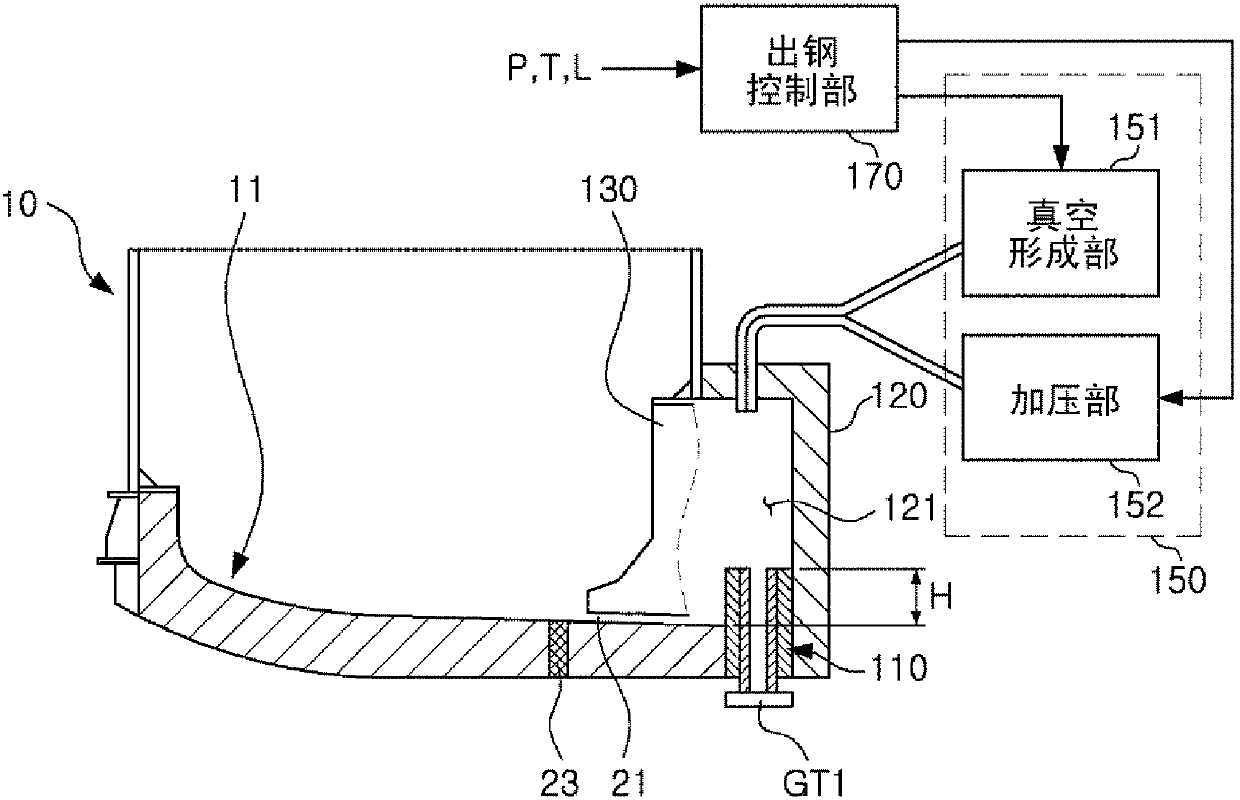

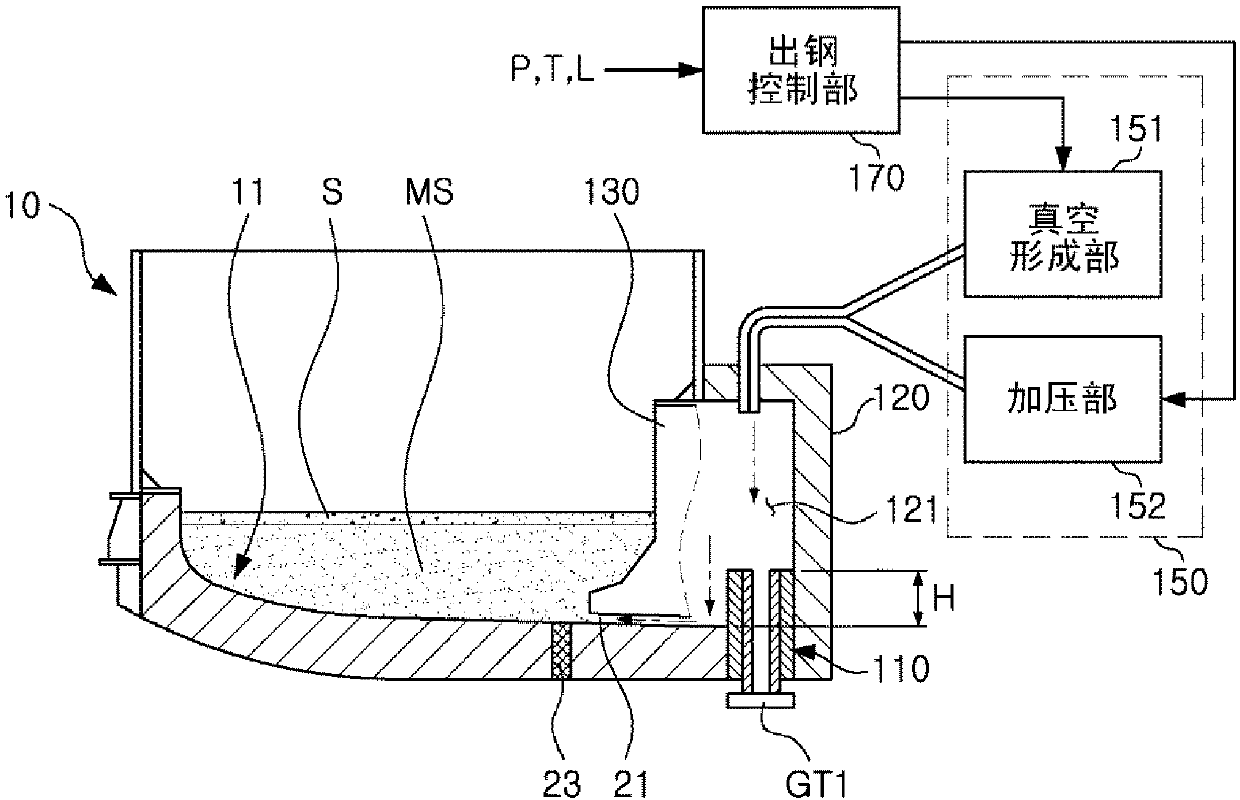

[0029] figure 1 It is a top view of a tapping device applied to a furnace body according to an embodiment of the present invention, figure 2 will be figure 1 Side view taken along line A-A`. on the one hand, Figure 10 to Figure 13 A furnace body to which a tapping device according to an embodiment of the present invention can be applied is shown.

[0030] Such as figure 1 as well as figure 2 As shown, the tapping device 100 according to an aspect of the present invention may be installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com