Optimal control method for energy saving of industrial circulating water based on double-layer structure predictive control

A technology of industrial circulating water and predictive control, applied in the direction of control/adjustment system, adaptive control, general control system, etc., can solve the problem of excessive branch flow, energy waste, and failure to meet the energy-saving requirements of industrial circulating water, etc. problems, to achieve the effect of reducing the output flow of the pipe network, reducing operating costs, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

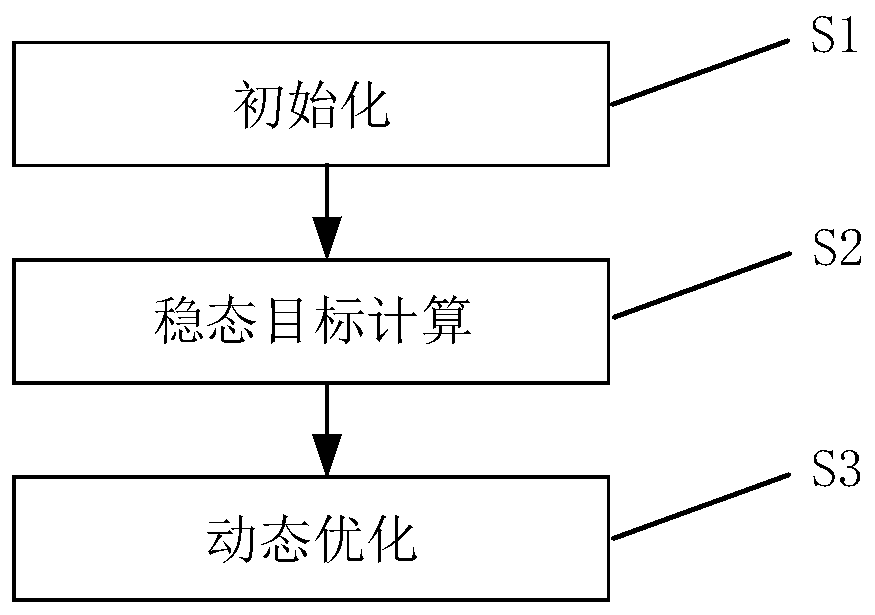

[0076] Such as figure 1 Shown is the flow chart of the method of the present invention.

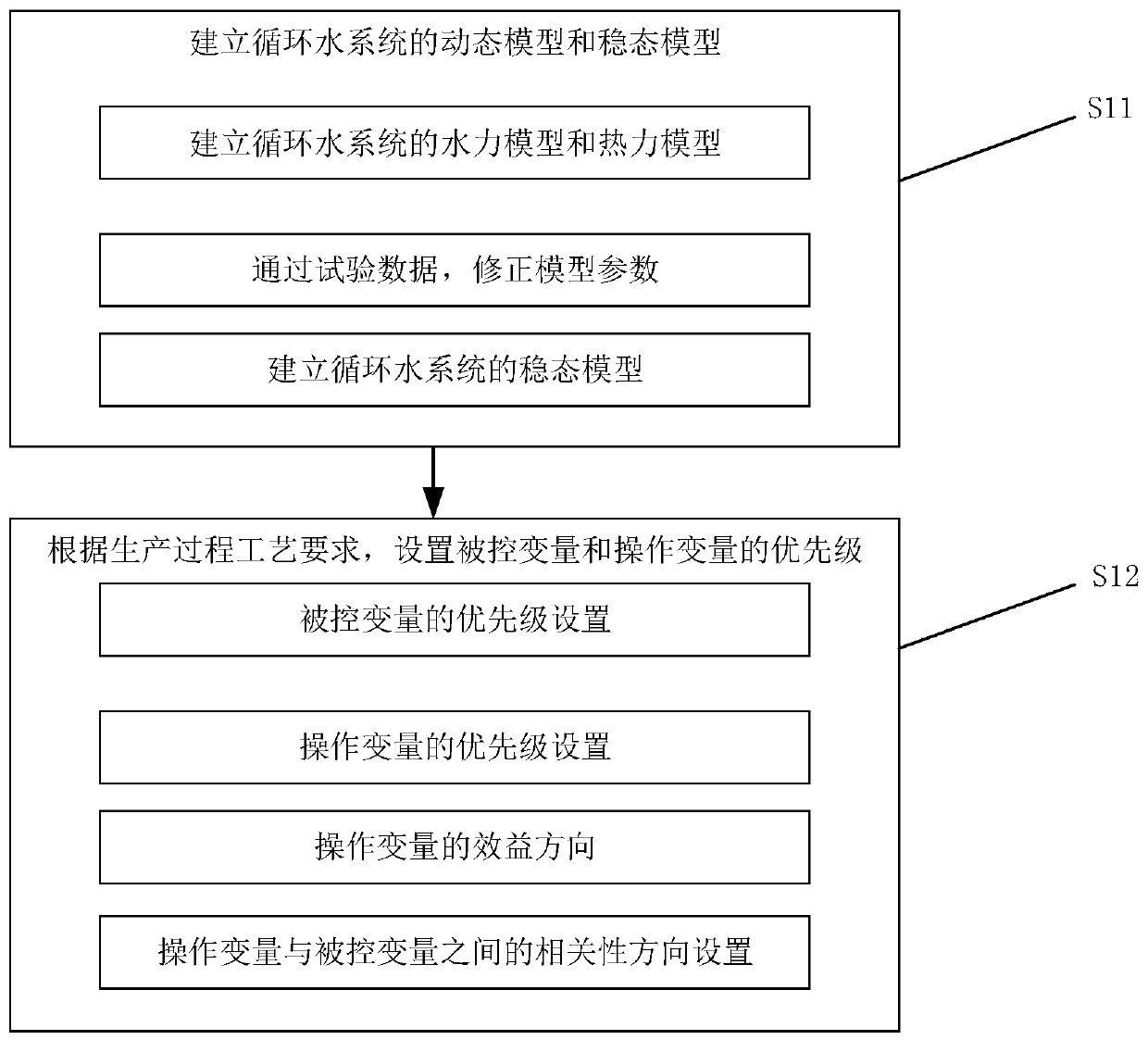

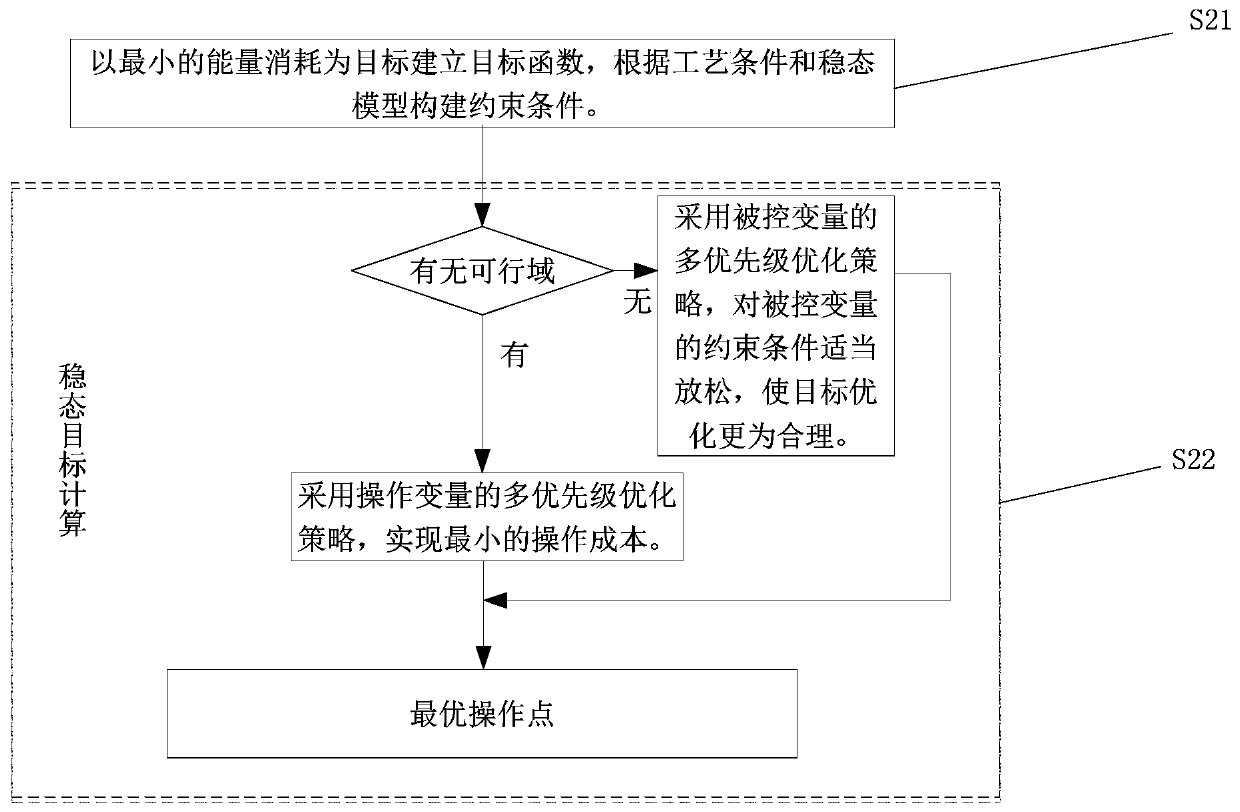

[0077] The present invention refers to an energy-saving optimization control method for industrial circulating water based on a double-layer structure predictive control of priority strategy, which is composed of a steady-state target calculation layer and a dynamic control layer. The steady-state target calculation layer adopts an economical self-optimization method to obtain the optimal The steady-state controlled variable value (temperature, pressure, flow) and the steady-state manipulated variable value (valve opening, pump operating frequency), the dynamic control layer receives the optimal steady-state value from the steady-state target calculation layer, and uses the prediction The control algorithm obtains the value of the manipulated variable at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com