Electric power optical cable fiber fusion sleeve and manufacturing method thereof

A technology of optical cable and electric power, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of fiber coating failure, fiber transmission interruption, etc., and achieve the effect of reducing operation and maintenance costs, reducing defects, and promoting safe operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

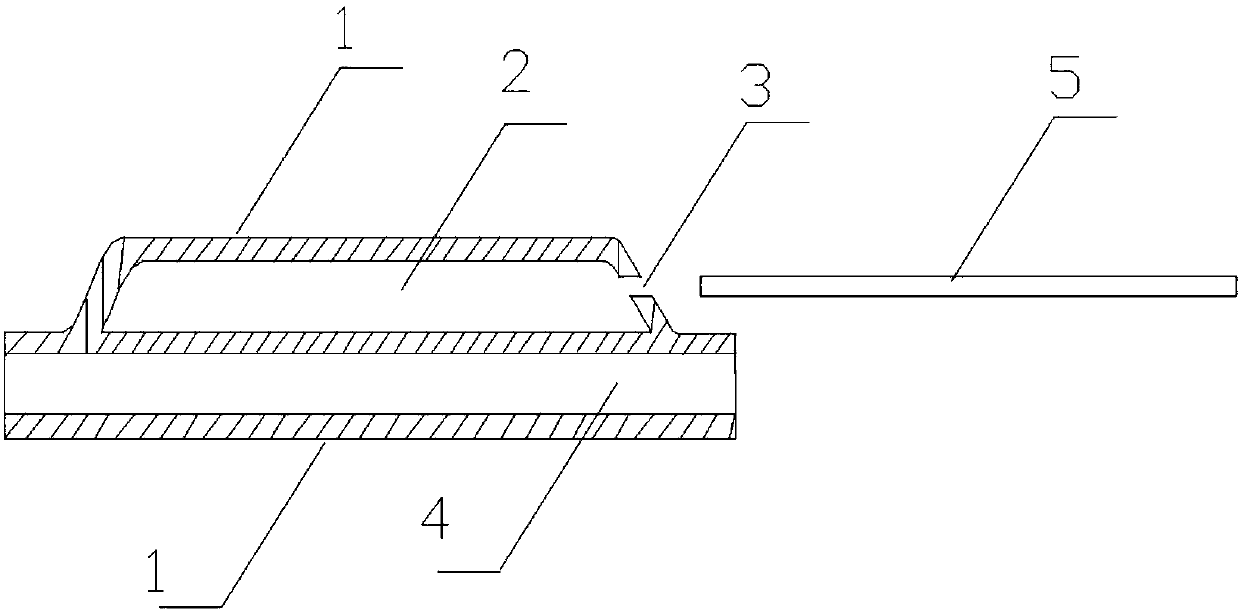

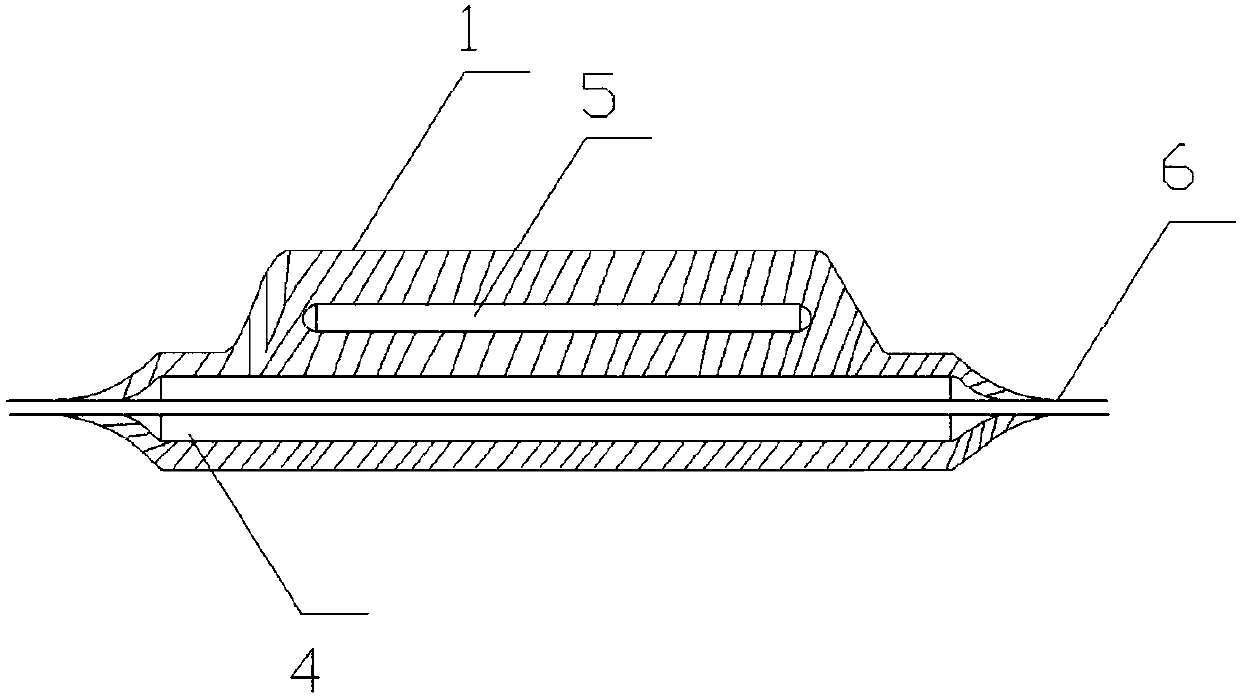

[0017] At present, the fused fiber sheath tube of domestic and foreign power optical cables adopts the fused fiber sheath tube of the telecommunication cable. Since the reinforcing shank of the fused fiber sheath tube is a steel wire with a diameter of 1.5mm and a length of 45mm, the fusion of this ferromagnetic material The fiber sheath tube will generate heat due to electromagnetic induction in a strong electromagnetic field environment, especially for power optical fiber cables used in AC ultra-high voltage substations, AC ultra-high voltage substations, AC high-voltage substations, power plant generators, transformers, and AC transmission lines. After splicing, during operation, the fiber optic channel is often interrupted due to heat and combustion of the fused fiber sheath tube, which directly threatens the safe production of the power grid. Due to the vigorous development of smart grids in recent years, power optical fiber communication has been rapidly built with smart ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com