Intelligent balancing device for frame body operation

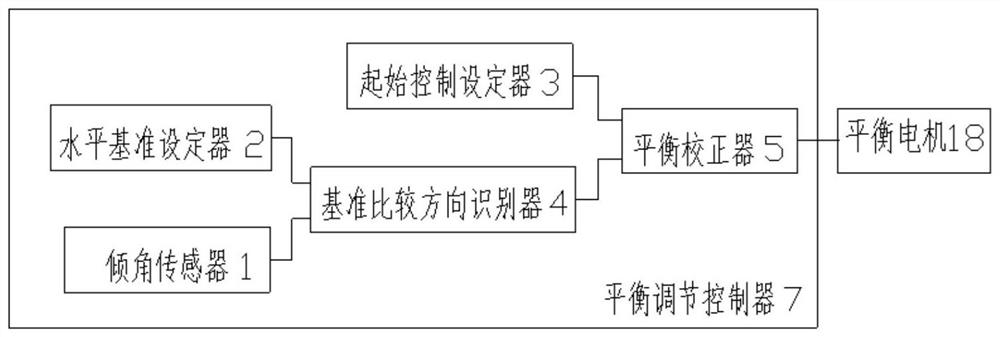

A balancing device and intelligent technology, which is applied in the field of compact racks, can solve the problems of unreasonable structural composition adjustment mode, untimely anti-falling balance effect, and poor balance effect, so as to achieve sensitive adjustment action and reduce or avoid accidents The effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

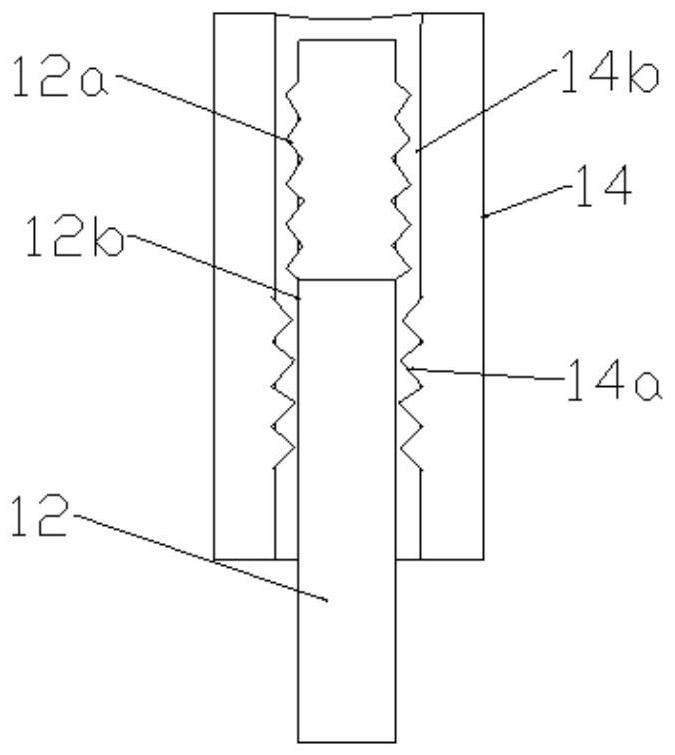

[0019] In embodiment 2, such as Figure 4 As shown, in this example, the kinematic coupling device of the correcting force is a composite multi-function correcting force kinematic coupling device, and its matching balance adapter is a compound matching balancing adapter. The composite multi-functional correction force motion coupling device includes composite rolling or sliding couplers fixedly connected to the lower end of the balance adjustment rod on the left and right sides and the upper and lower walls of the inner or outer side of the track respectively. The two bearing devices of the corresponding upper and lower parts, the bearing 17a of its lower bearing device 17-2 is in rolling connection with the lower wall surface 16b of the protruding part of the track 16, and the bearing 17a of the upper bearing device 17-1 is connected with the upper wall surface of the track. 16a is rollingly connected, and the bearing shaft 17b of the upper and lower bearing devices is fixedl...

Embodiment 3

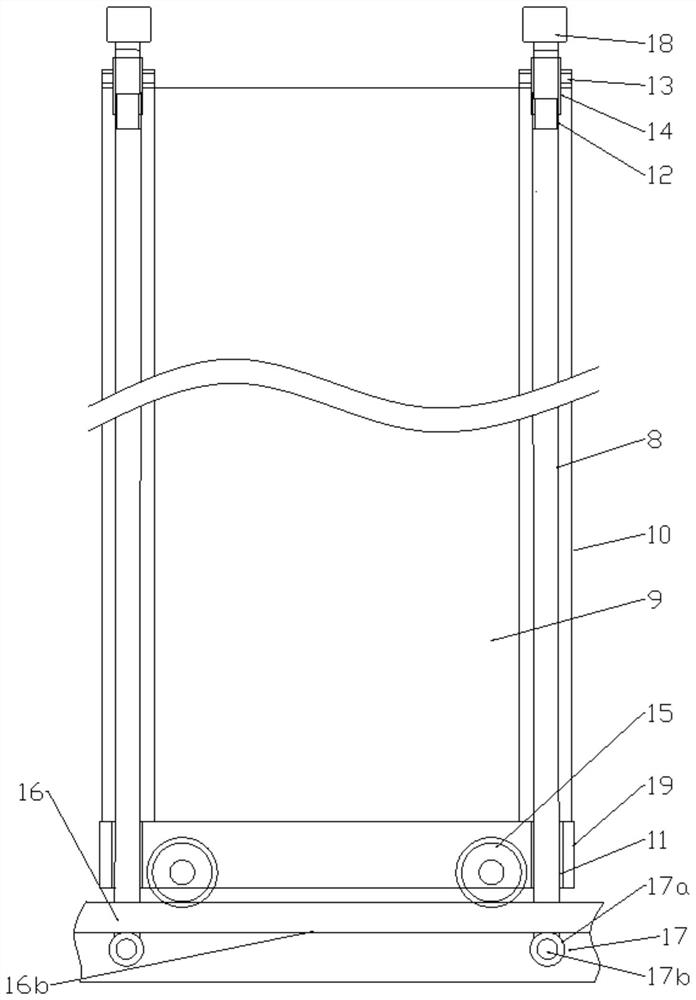

[0024] In embodiment 3, such as Figure 5 with 6 shown. The balance adjustment rods are respectively set in the inner cavity of the frame-type columns on the left and right sides in the middle of the frame body. The two rails at both ends of the frame body are respectively equipped with a composite multifunctional correction force motion coupling device, and its composite multifunctional correction effect The force motion coupling device also includes a linkage integrated synchronous transmission rod 27, and the two ends of the linkage integrated synchronous transmission rod are respectively fixedly connected to the bearing shaft 17b or the sliding shaft of the rolling or sliding coupler of the two tracks of the compact shelf. The bearing 17a or sliding body of its rolling or sliding coupler is respectively rolling or slidingly connected to the upper wall surface 16a of the track of the frame body and the lower wall surface 16b of the protrusion on one side of the track. The...

Embodiment 4

[0025] In embodiment 4, such as Figure 7 shown. The two tracks corresponding to the two ends of the frame body 9 are respectively provided with balance adjustment rods corresponding to each other on the left and right sides, and the two pairs of left and right balance adjustment rods at the two ends of the frame body are respectively arranged in the corresponding two sides of the column near the track, or next to the column. The outer part of the frame. The similar balance adapter of the balance adjustment rod is connected with the balance motor through a bridge-type co-balance correction driving device. The bridge-type co-balance correction transmission device includes a balance drive main shaft 25 arranged in the longitudinal middle of the top wall of the frame body, which is respectively connected to the balance drive main shaft at both ends of the balance drive main shaft through a plane 90-degree direction-changing bevel gear transmission 20a and the balance drive main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com