A substation hard platen verification auxiliary control device

A hard press plate and substation technology, which is applied in the field of substation hard press plate verification auxiliary control devices, can solve problems such as high cost and low verification efficiency, and achieve the effects of reducing losses, reducing verification time, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

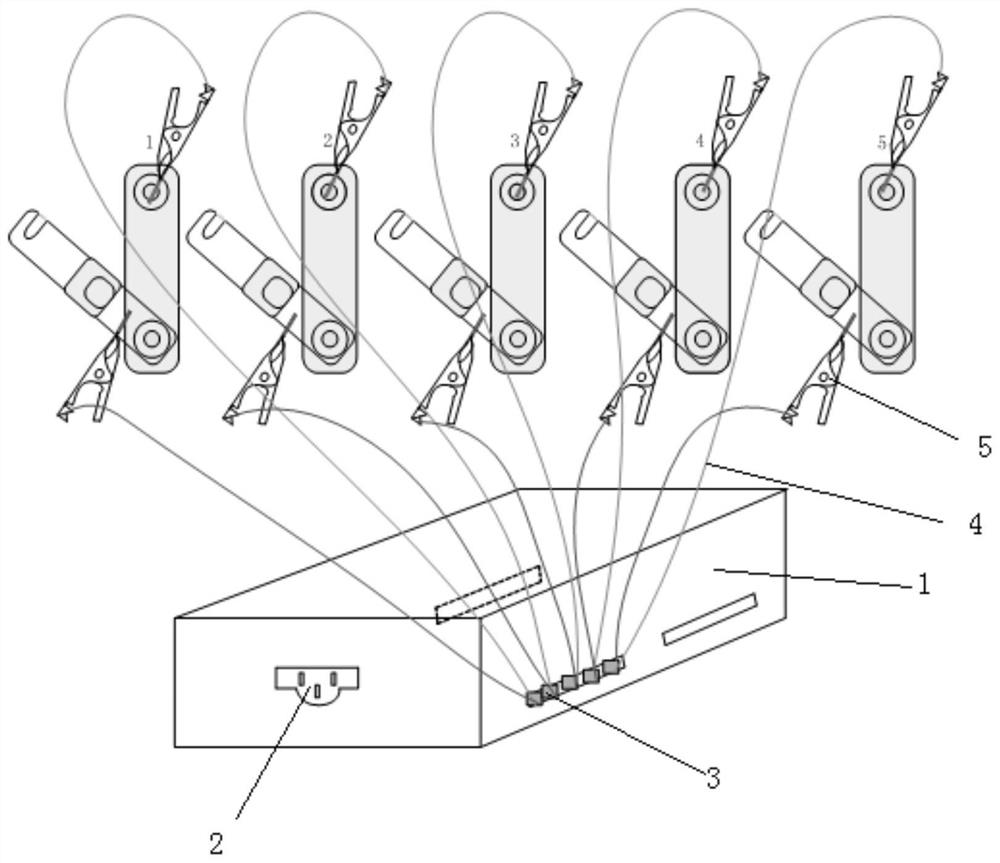

[0014] Examples such as figure 1 , figure 2 As shown, it includes a housing 1, and the housing 1 is provided with a control board and an auxiliary power supply connected to the circuit of the control board. The body 1 is provided with a group of jacks connected with the control main board, and a connector is arranged in the jack, and the connector includes a plug-in terminal 3 adapted to the jack, and a group of two plug-in terminals 3 is provided on the plug-in terminal 3 A connecting wire 4, the other end of the connecting wire 4 is provided with a small flat-head alligator clip 5, and the small flat-head alligator clip 5 is covered with an insulating sleeve. The plug-in terminal 3 can perfectly solve the connection problem between the connecting wire 4 and the auxiliary control device. The consumables are moderate and the operation is convenient. The lower end of the pressure plate has advantages in terms of reliability and connection and removal operations. The length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com