Automatic transplanting, turnover and tightening machine for robot

A robot and tightening machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long cycle time, reduced precision, equipment and equipment errors, etc., to achieve faster work cycle, reduce the number of equipment, and reduce errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

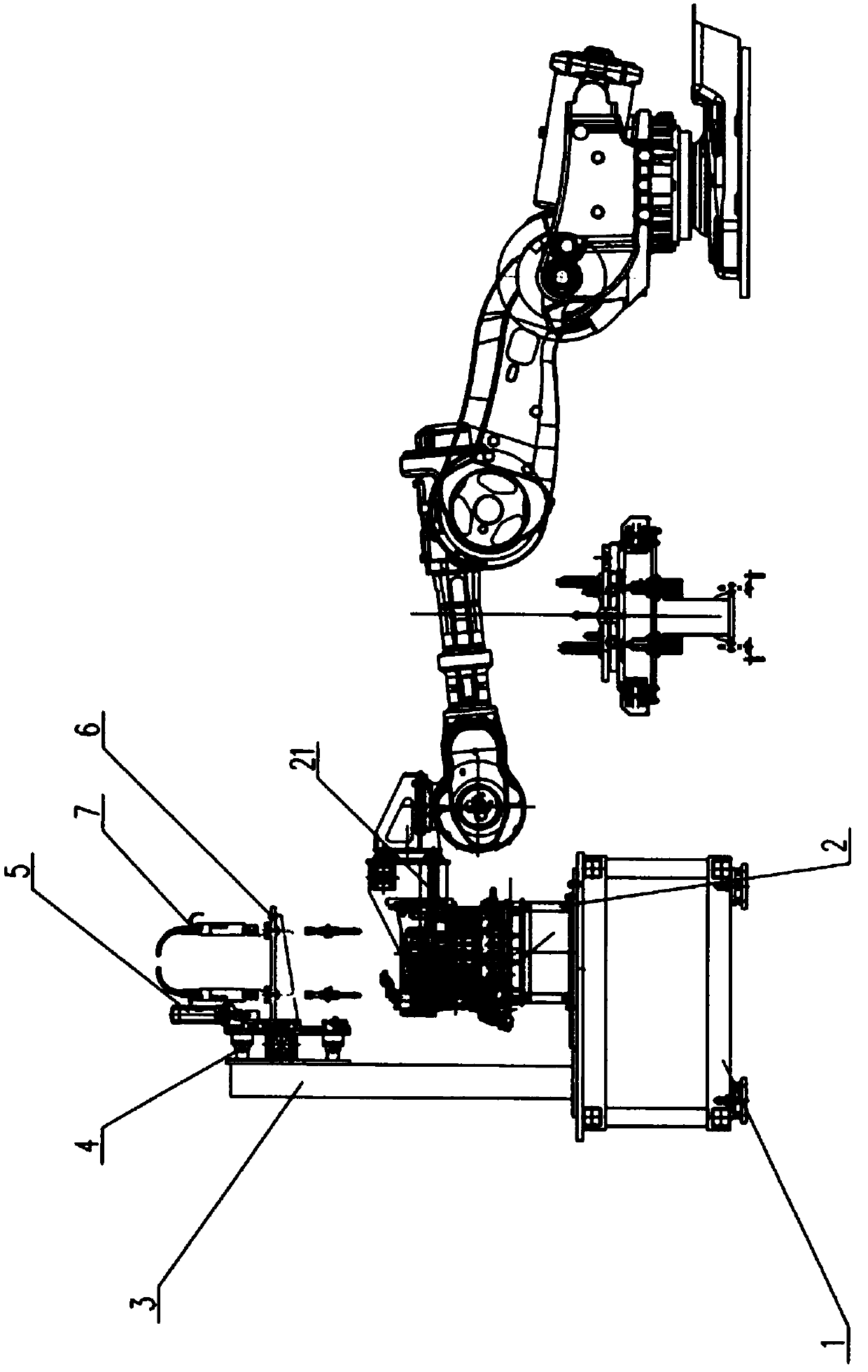

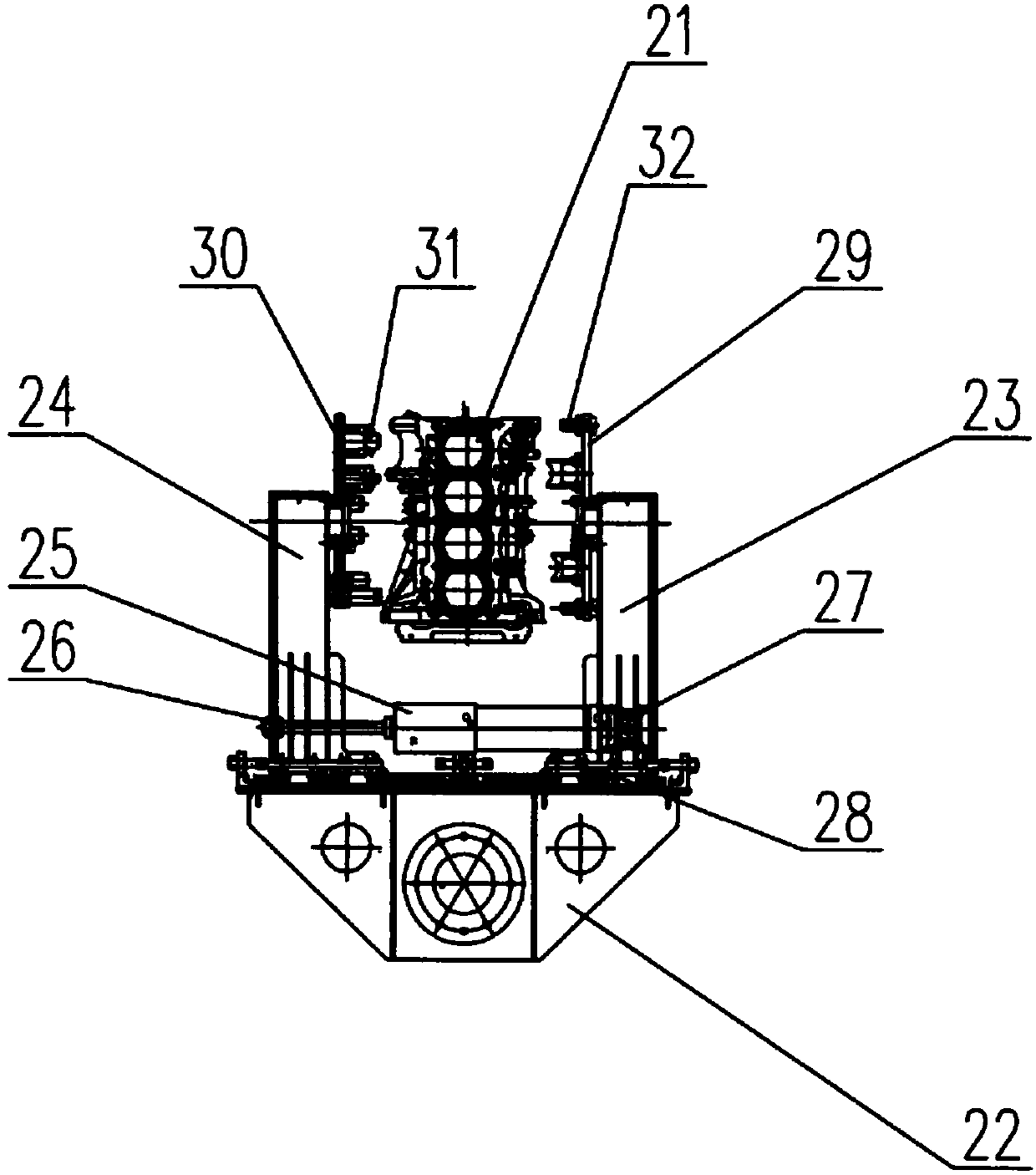

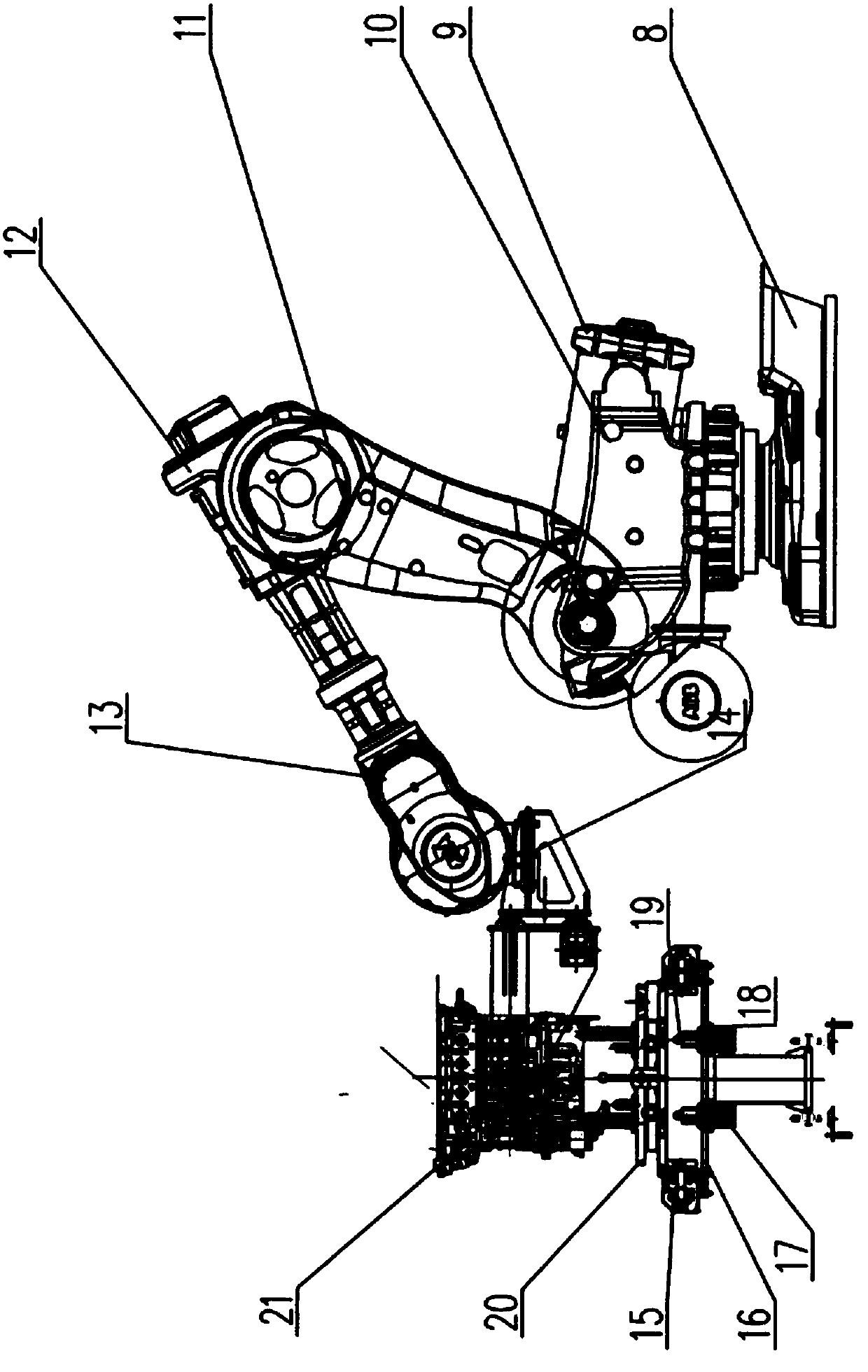

[0016] Such as figure 1 , figure 2 As shown, a robot automatic transplanting, turning and tightening machine includes a worktable 1, a workpiece positioning device 2, a column 3, a first linear guide 4, a second cylinder 5, a shaft mounting seat 6, a tightening shaft 7, and a robot base 8. Buffer cylinder 9, robot swivel arm 10, first robot arm 11, second robot arm 12, third robot arm 13, robot claw 14, conveyor roller 15, first cylinder mounting plate 16, first cylinder 17, Bushing 18, positioning pin 19, pallet 20, workpiece 21, fixture mounting seat 22, right arm 23, left arm 24, third cylinder 25, lock nut 26, cylinder seat 27, second linear guide 28, right positioning plate 29. Left positioning plate 30, left positioning pin 31, right positioning pin 32, servo motor 33, first screw base 34, motor base 35, coupling 36, first bearing 37, ball screw 38, second wire The rod seat 39, the second bearing 40, the screw support 41, the second cylinder mounting plate 42, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com