Vacuum cavity and preparation method thereof

A vacuum chamber and chamber wall technology, which is applied in the field of vacuum chamber and vacuum chamber preparation, can solve the problems of gas storage, dirt storage of supporting parts, etc., and achieve the effect of avoiding pollution and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. Examples of the embodiments are shown in the accompanying drawings, in which the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

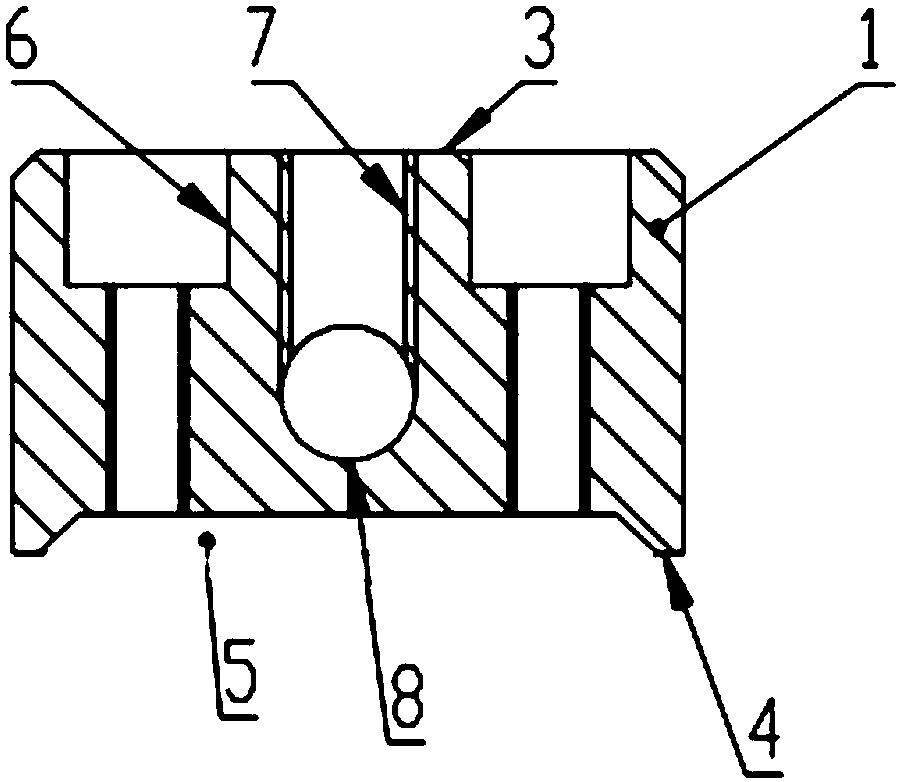

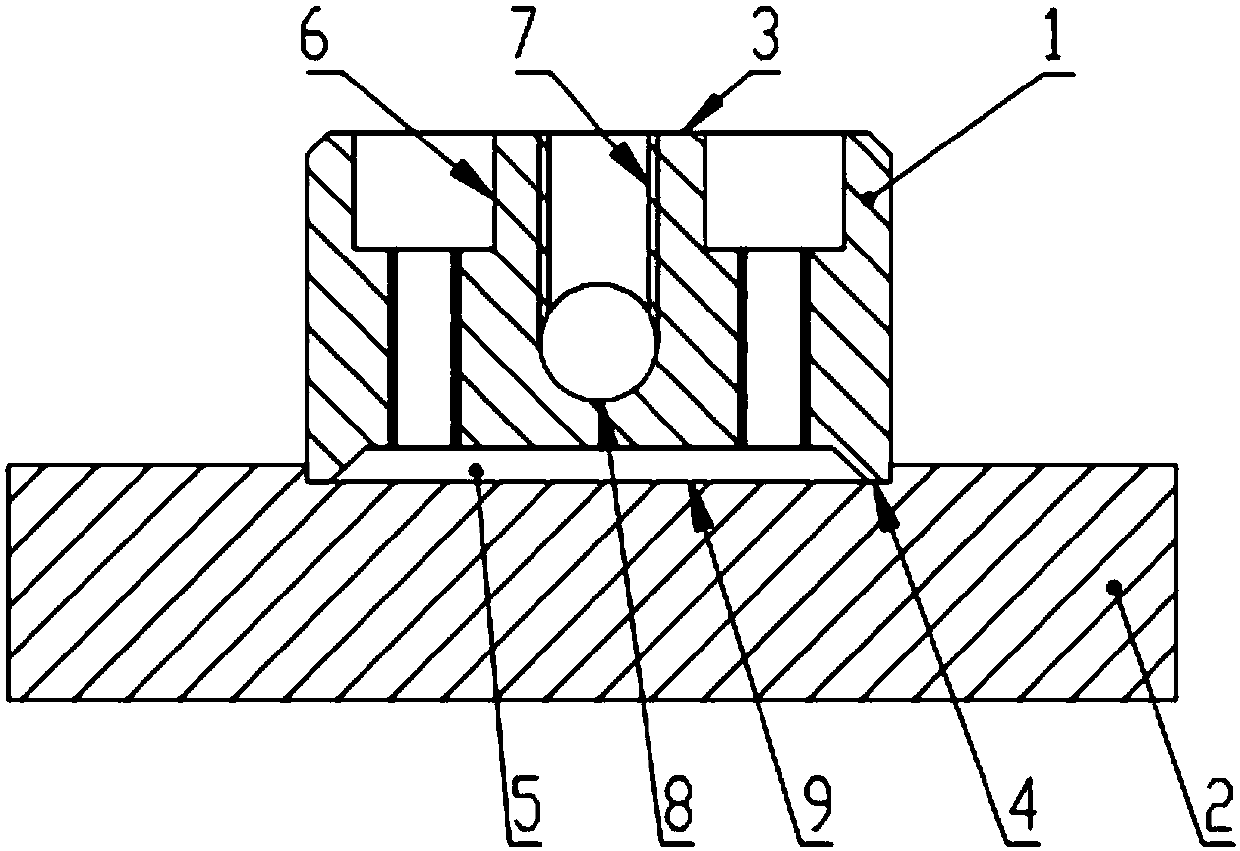

[0023] The invention discloses a vacuum chamber, which has: a support 1 and a chamber wall 2. The support 1 is in the vacuum chamber, and the support 1 serves as a fixed support or positioning support for the assembly of other components, which requires the support 1 to have a certain shape and position tolerance.

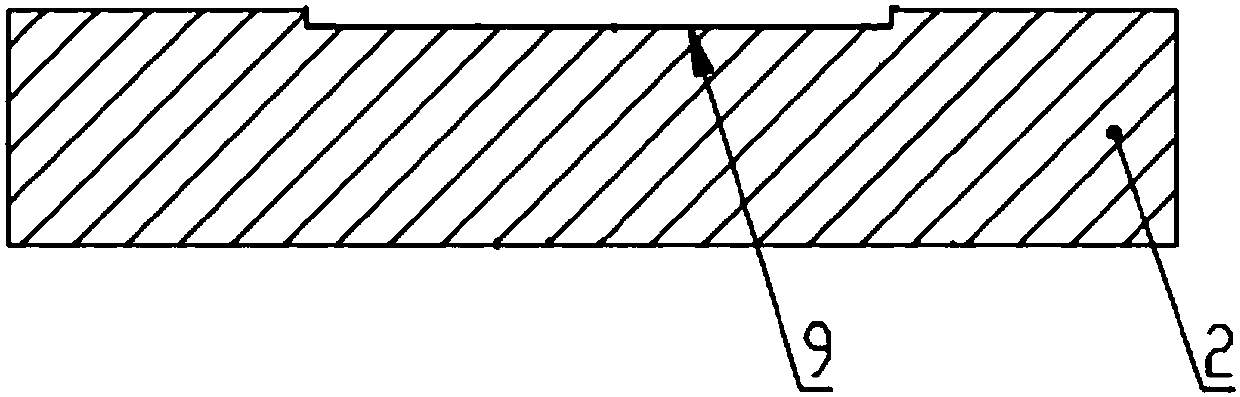

[0024] A positioning surface 9 is formed on the chamber wall 2, and the bottom surface 4 of the support 1 is located on the positioning surface 9. The support 1 and the chamber wall 2 are conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com