A preparation process of a vehicle front panel seat

A preparation process and technology of plate base, which is applied in the field of preparation process of vehicle front plate base, can solve the problems of high processing labor intensity and low processing efficiency, achieve control of shrinkage ratio and surface quality, reduce production cost, and avoid formation of oxidation layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

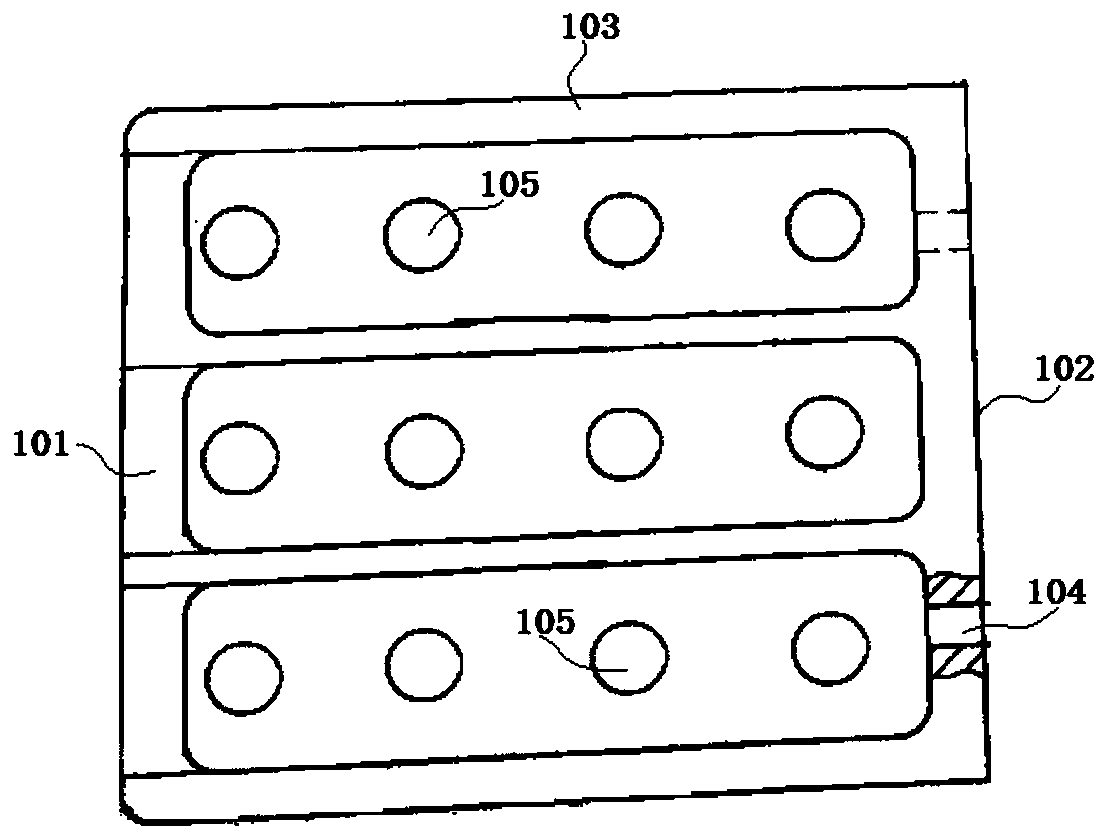

[0047] Such as Figure 1-Figure 3Shown is a schematic structural diagram of a vehicle front panel seat in the prior art, the front panel seat includes a base 101, a back panel 102 is provided on one side of the base 101, and four vertical panels are evenly spaced on the base 101 103 is connected to the back plate 102, and the two sides of the back plate 102 are symmetrically provided with fixing holes 104, and the base 101 is provided with a plurality of mounting holes 105 distributed in strips between two adjacent vertical plates 103, and a plurality of The mounting holes 105 are evenly spaced. In practice, the processing accuracy requirements for the mounting holes 105 and the fixing holes 104 are relatively high, especially for multiple closely arranged mounting holes 105, the dimensional processing tolerance is required to be between ±0.5mm, and the surface quality of the hole walls is extremely high. The advanced lost foam casting technology is difficult to accurately co...

Embodiment 2

[0058] The preparation process of a vehicle front panel seat of this embodiment is basically the same as that of Embodiment 1. Furthermore, the design of the gating system in this embodiment cannot be ignored, such as Figure 4 As shown, the gating system in this embodiment includes a sprue 300, a runner, and a sprue connected in sequence. The sprue is connected to the foam pattern, and the top of the sprue 300 is provided with a sprue whose opening size tapers downward. The spout cup 200, wherein the sprue cup 200 is a non-axisymmetric structure. During pouring, the molten steel is poured from the sprue cup 200, and enters the foam pattern through the sprue 300, the runner and the sprue in turn. The industry usually adopts a conical or funnel-shaped gate with good diversion effect. Cup 200, but in practical application, molten steel is still prone to problems such as impurities and oxidation, and casting defects such as slag inclusions and pores will still be formed in castin...

Embodiment 3

[0062] The preparation process of a vehicle frontal plate seat of this embodiment is basically the same as that of Embodiment 2. Furthermore, the bottom of the sprue 300 in this embodiment is also provided with a filter screen 302 made of ceramic material, such as Figure 5 As shown, specifically, the bottom of the sprue 300 is provided with an upper connection section 301 whose opening size gradually expands from top to bottom, and a lower connection section 303 with an opening size that gradually shrinks from top to bottom is provided below the upper connection section 301. 302 is disposed between the upper connection section 301 and the lower connection section 303 . The diameter of the filter screen 302 is at least twice (in this embodiment, twice) the inner diameter of the sprue 300. The filter screen 302 is evenly provided with filter holes, and the diameter of the filter holes is 2-4mm. The spacing (the spacing between the walls of two adjacent filter holes) is 5-6mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com