Catalyst for preparing 2-methyltetrahydrofuran by hydrogenation and its use method

A technology for the preparation of methyl tetrahydrofuran and hydrogen, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Environmental protection and other issues, to achieve the effects of mild reaction conditions, high selectivity, and simple operation of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

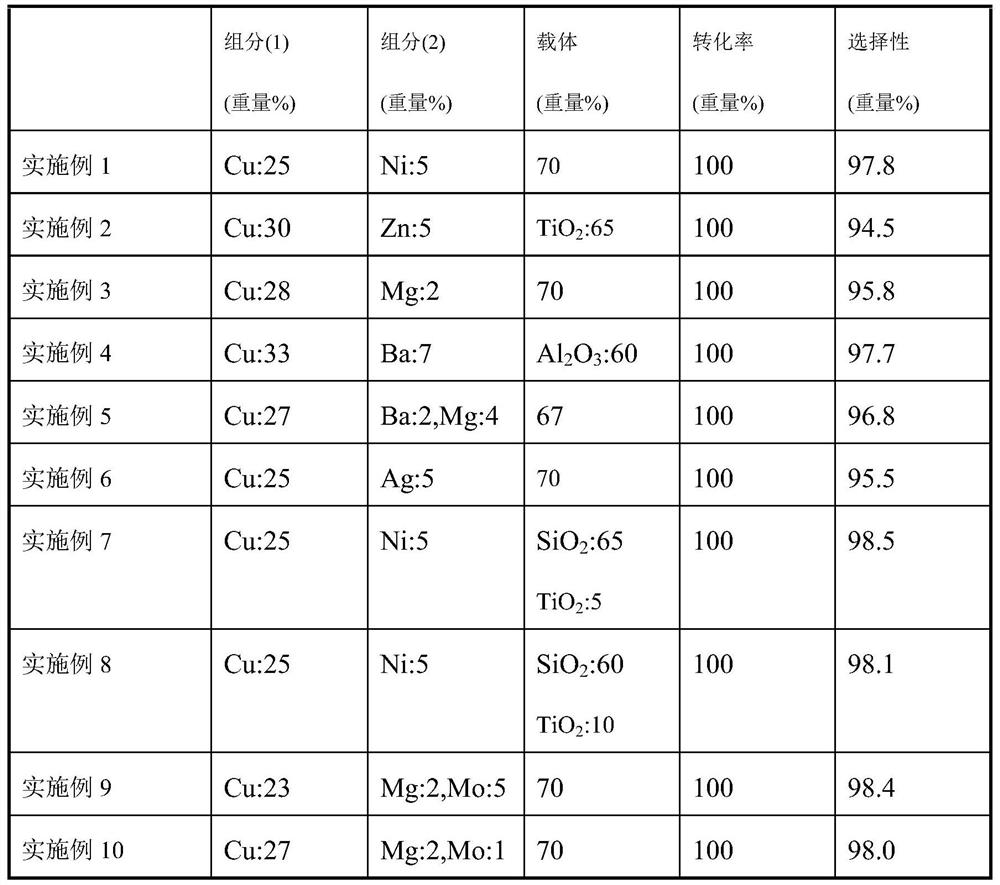

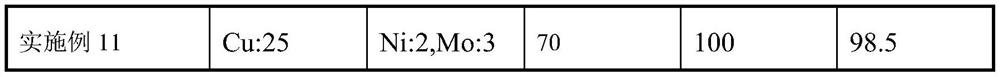

Embodiment 1

[0033] Take copper nitrate and nickel nitrate in proportion and add them to the silicon oxide aqueous solution (Cu: Ni: silicon oxide = 25:5:70, weight ratio), stir evenly at room temperature and adjust the pH by adding a precipitant until the precipitation of Cu and Ni ions is complete. Stirring was continued for 2 hours. The resulting solution was filtered, dried and calcined to obtain a catalyst precursor. Pass hydrogen through the precursor at a pressure of 0.3-0.5MPa, the volume ratio of hydrogen to catalyst is 350:1, raise the temperature of the catalyst bed to 300°C within 36 hours, and complete the reduction at constant temperature for 8 hours to obtain a Cu-based catalyst Cu-Ni / SiO 2 .

[0034] Adding Cu-based Catalyst Cu-Ni / SiO in Continuous Fixed-bed Reactor 2 , at a reaction temperature of 160°C and a pressure of 2.8Mpa, the molar ratio of hydrogen to levulinic acid ester is 80, and the mass space velocity of levulinic acid ester is 1.0h -1 , the conversion rat...

Embodiment 2

[0036] Add copper nitrate and zinc nitrate in proportion to titanium oxide aqueous solution (Cu: Zn: titanium oxide = 30: 5: 65, weight ratio), stir evenly at room temperature and adjust the pH by adding a precipitant until Cu and Zn ions are completely precipitated Stirring was continued for 2 hours. The resulting solution was filtered, dried and calcined to obtain a catalyst precursor. Pass hydrogen through the precursor at a pressure of 0.3-0.5MPa, the volume ratio of hydrogen to catalyst is 200:1, raise the temperature of the catalyst bed to 250°C within 12 hours, and complete the reduction at constant temperature for 9 hours to obtain a Cu-based catalyst Cu-Zn / TiO 2 .

[0037] Adding Cu-based Catalyst Cu-Zn / TiO in Continuous Fixed-bed Reactor 2 , at a reaction temperature of 140°C, a pressure of 2.5Mpa, a molar ratio of hydrogen to levulinate of 90, and a mass space velocity of levulinate of 0.5h -1 , the conversion rate of levulinic acid ester is 100%, and the select...

Embodiment 3

[0039] Take copper nitrate and magnesium acetate in proportion and add them to the aqueous silica solution (Cu: Mg: silica = 28:2:70, weight ratio), stir well at room temperature and adjust the pH by adding a precipitant until Cu and Mg ions are completely precipitated Stirring was continued for 2 hours. The resulting solution was filtered, dried and calcined to obtain a catalyst precursor. Pass hydrogen through the precursor at a pressure of 0.3-0.5MPa, the volume ratio of hydrogen to catalyst is 250:1, raise the temperature of the catalyst bed to 350°C within 36 hours, and complete the reduction at constant temperature for 9 hours to obtain a Cu-based catalyst Cu-Mg / SiO 2 .

[0040] Addition of Cu-Mg / SiO in Continuous Fixed Bed Reactor 2 Catalyst, at a reaction temperature of 200°C, a pressure of 2.5Mpa, a molar ratio of hydrogen to levulinic acid ester of 100, and a mass space velocity of levulinic acid ester of 1.20h -1 , the conversion rate of levulinic acid ester is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com