Noncontact intelligent multi-sound electronic horn

An electronic horn and non-contact technology, which is applied in the direction of electrical components, transducer acoustic response prevention, sensors, etc., can solve the problem of single sound, achieve the effect of intelligent horn function, reduce noise hazards, and improve the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

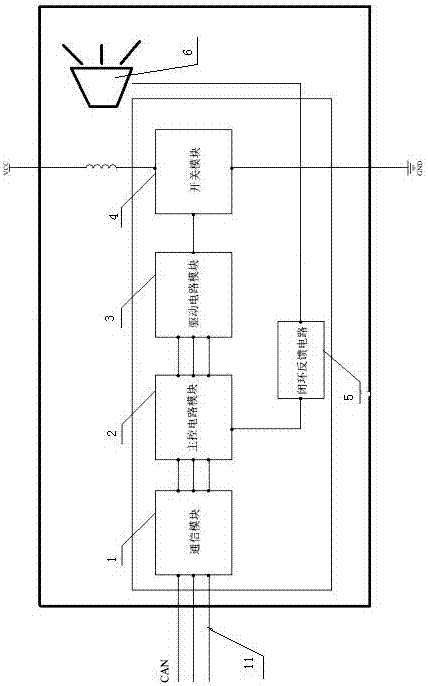

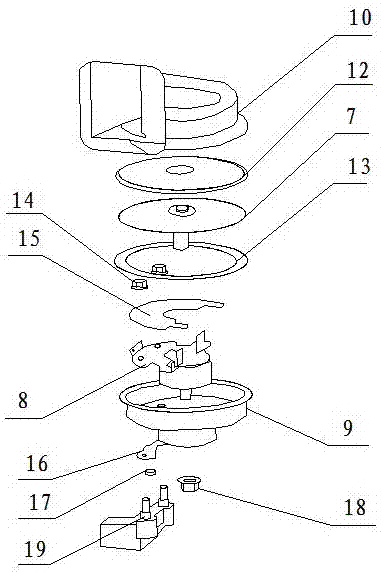

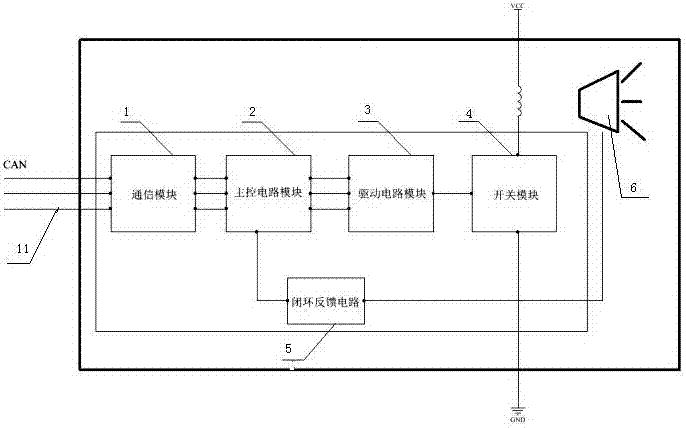

[0014] A non-contact intelligent multi-tone electronic horn, its composition includes: a circuit board assembly and a mechanical assembly, the circuit board assembly is composed of a communication module 1, a main control circuit module 2, a drive circuit module 3, a switch module 4 and a closed-loop feedback The circuit 5 is formed, and the circuit board assembly is connected with the coil assembly in the mechanical assembly by welding to form a speaker system 6, realizing a non-contact intelligent multi-tone electronic speaker, and the mechanical assembly is composed of a diaphragm assembly 7. It is composed of a coil assembly 8, a housing assembly 9, a plastic shell assembly 10 and auxiliary parts.

Embodiment 2

[0016] According to the non-contact intelligent multi-tone electronic horn described in embodiment 1, the described communication module is connected with the vehicle CAN bus 11, the described main control circuit module is connected with the described communication module, and the described driving circuit module It is connected with the main control circuit module, the switch module is connected with the driving circuit module, and the closed-loop feedback circuit is connected with the main control circuit module.

Embodiment 3

[0018] According to the non-contact intelligent multi-tone electronic horn described in embodiment 1 or 2, the auxiliary parts have a gland 12, a paper gasket 13, a nut A14, a PCB board 15, a sealing rubber ring 16, a breathable membrane 17, and a nut B18 and terminal post 19, the plastic shell assembly is connected to the gland, the gland is connected to the diaphragm assembly, the diaphragm assembly is connected to the paper gasket, and the paper The washer is connected to the PCB board, the PCB board is respectively connected to the nut A and the coil assembly, the coil assembly is connected to the housing assembly, and the housing assembly is respectively It is connected with the sealing rubber ring, the nut B and the terminal post, and the sealing rubber ring is connected with the gas-permeable membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com