Shooting triggering system suitable for ultra-high-speed camera in brittle material research

A brittle material and ultra-high-speed technology, applied in parts of TV systems, image communication, color TV parts, etc., to overcome the effect of inaccurate shooting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

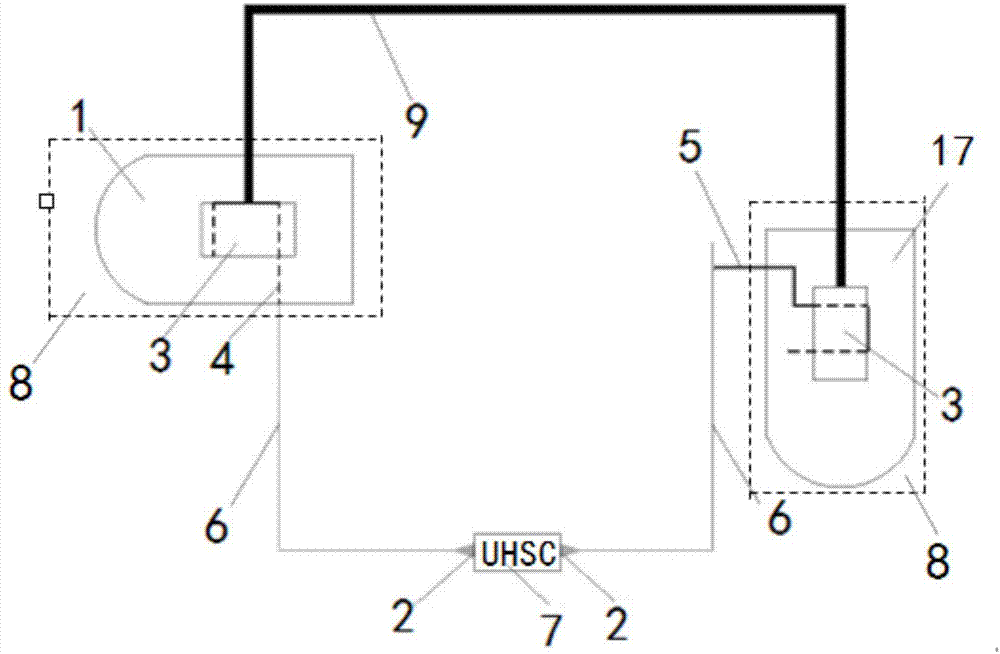

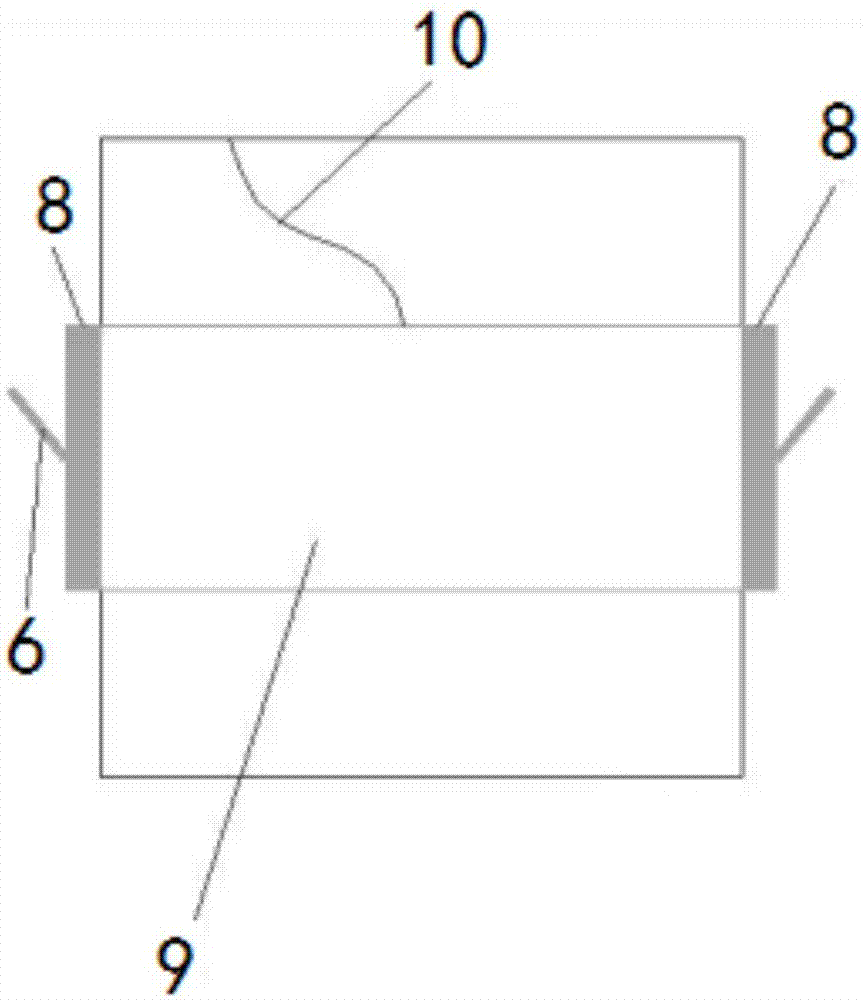

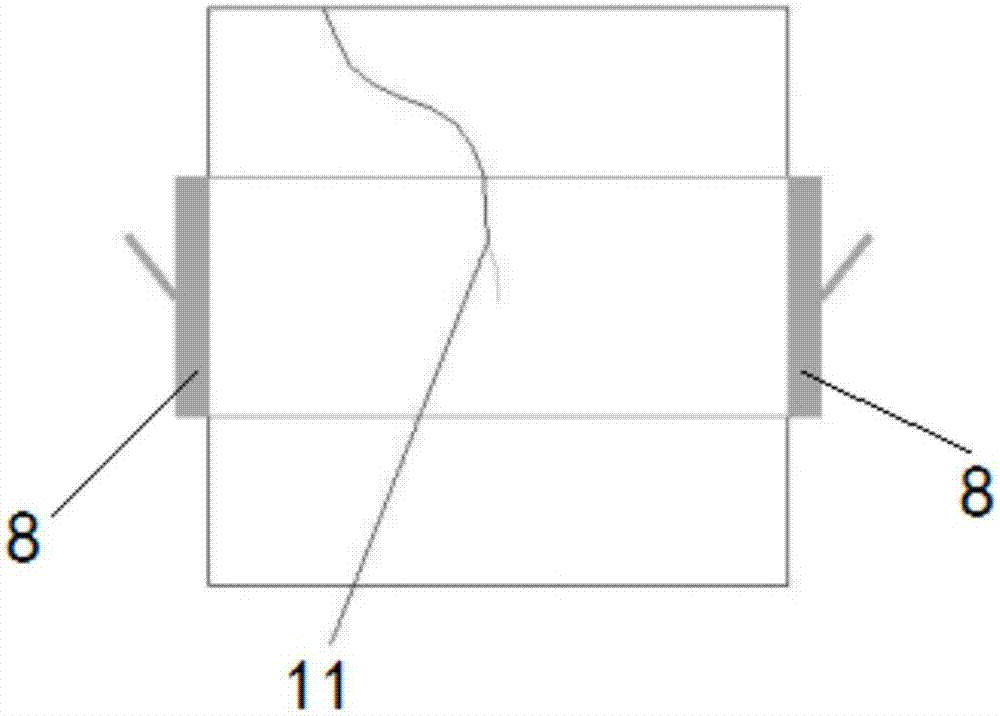

[0024] The present invention is applicable to the shooting and triggering system of ultra-high-speed cameras in the research of brittle materials, such as figure 1 As shown, it includes conductive sheet a1, conductive sheet b17 and ultra-high-speed camera 7; conductive sheet a1, conductive sheet b17 are connected with copper-silver conductive coating 9, and copper-silver conductive coating 9 is applied to the surface of concrete specimen 14; conductive The sheet a1 is connected to the central copper wire 4 of the coaxial cable, the conductive sheet b17 is connected to the mesh conductive layer line 5 of the coaxial cable, the connection between the conductive sheet a1 and the central copper wire 4 of the coaxial cable, and the conductive sheet b17 is connected to the mesh conductive layer of the coaxial cable. The connection of the layer wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com