A high-temperature cycle removal method for carbon dioxide based on a rotary fixed bed

A technology of carbon dioxide and high-temperature circulation, applied in the direction of direct carbon dioxide emission reduction, chemical instruments and methods, separation methods, etc., can solve the problems of high control difficulty, wear of absorbent particles, complex system, etc., and achieve simple removal process and particle elimination Collision wear, reducing the effect of operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

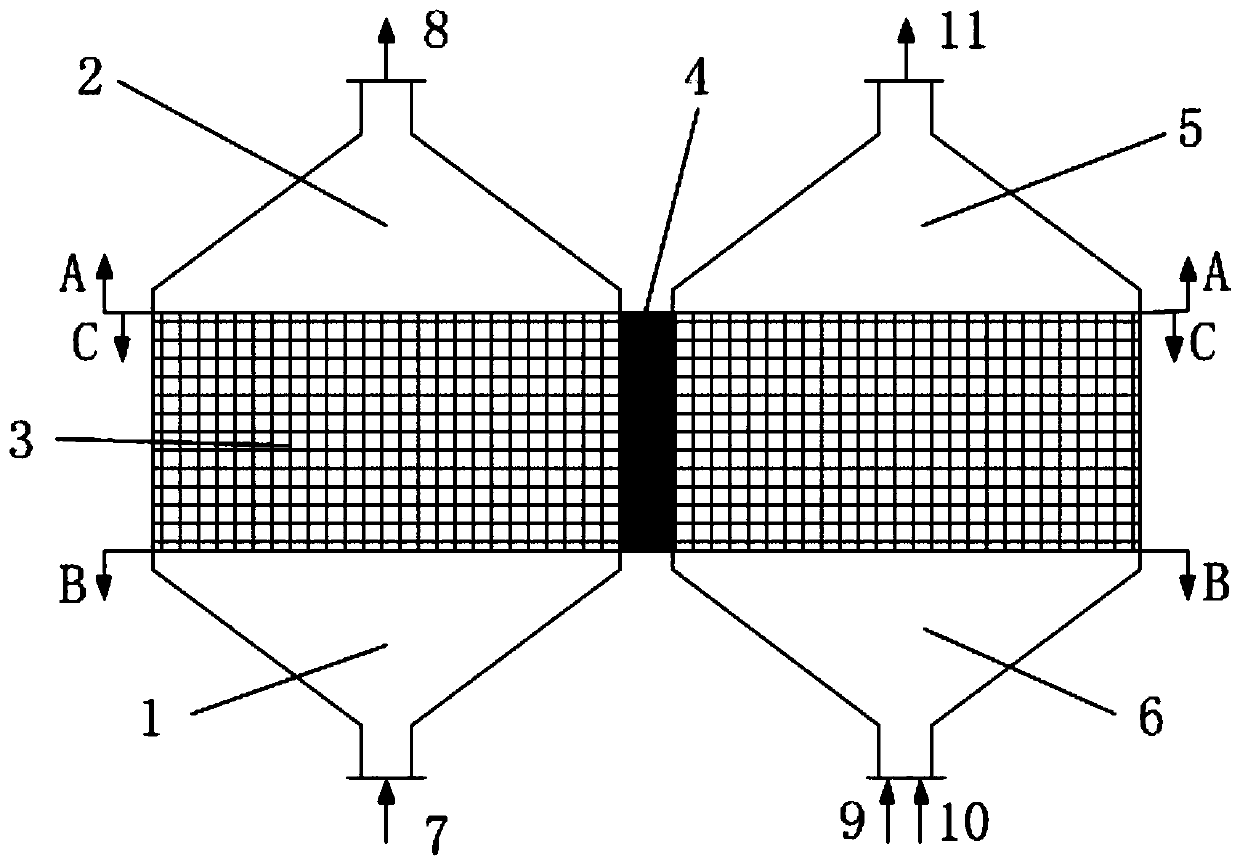

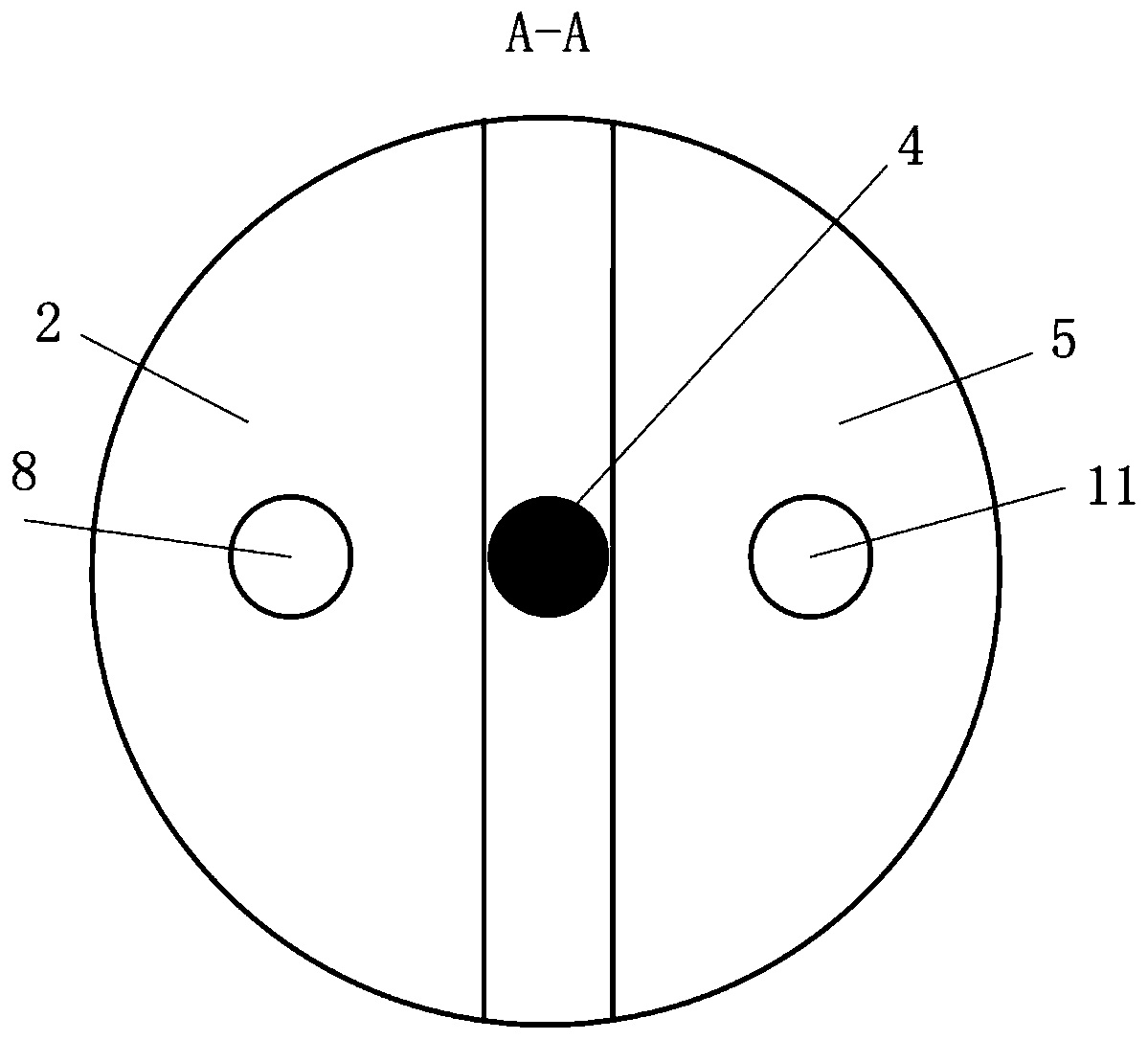

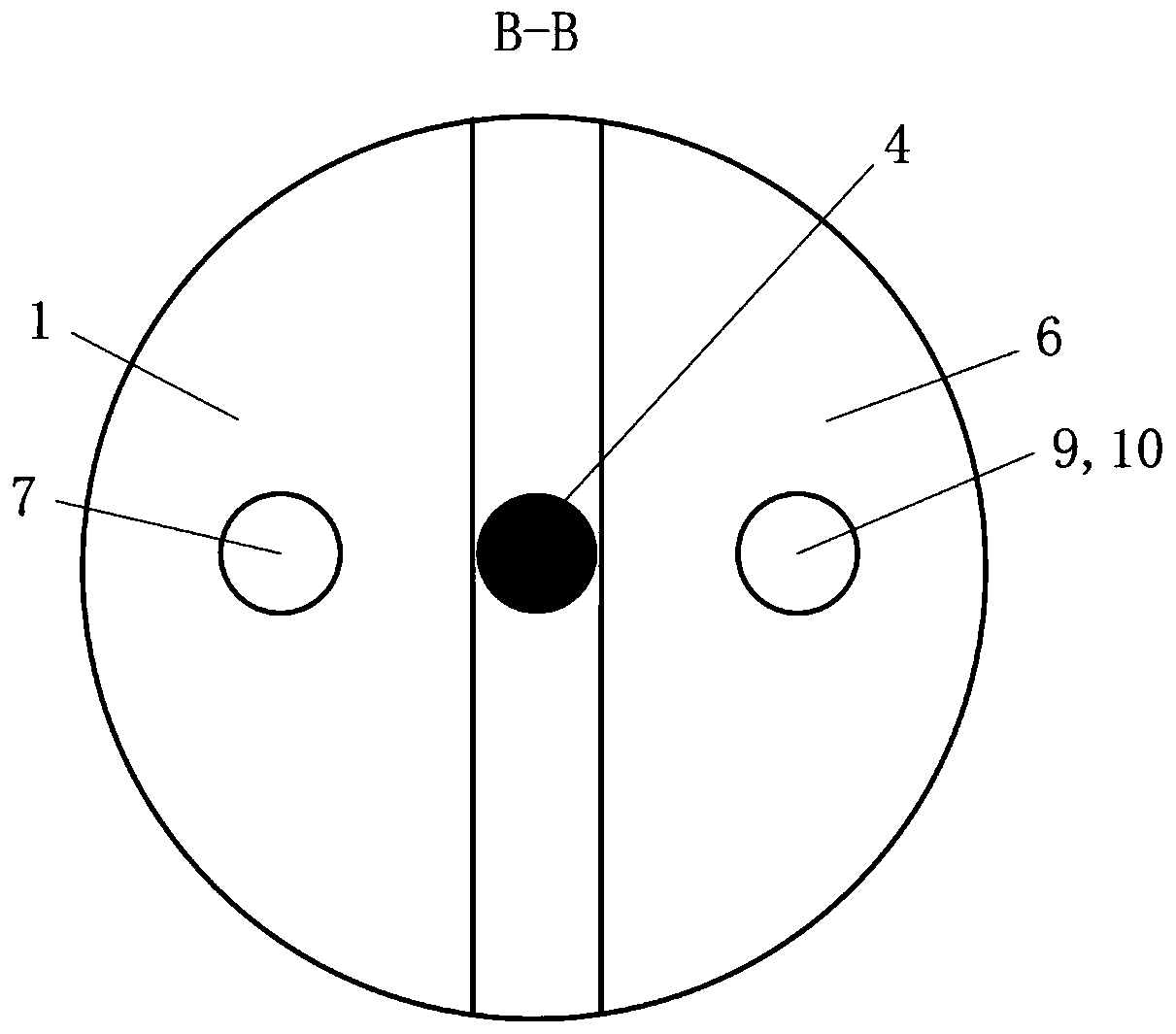

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, the inlet channel 1 on the flue gas side, the outlet channel 2 on the flue gas side, the inlet channel 6 on the fuel gas side, and the outlet channel 5 on the fuel gas side are all fixed, and only the fixed bed rotor 3 rotates periodically.

[0026] The flue gas 7 with a temperature of 500-700°C is sent in from the flue gas side inlet channel 1. When the flue gas 7 flows upward through the fixed bed rotor 3, the CO in the flue gas 7 2 Removed by calcium-based absorbent packing on the flue gas side and forms CaCO 3 , CO removal 2 The rear flue gas 8 is discharged from the flue gas side outlet channel 2. At this time, the CaO in the filler is converted into CaCO through carbonation reaction. 3 ; As the rotor 3 continues to rotate around the rotating shaft 4, the stuffing on the flue gas side rotates to the fuel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com