Variable speed mechanism for tractor

A transmission mechanism, tractor technology, applied in the direction of mechanical equipment, gear transmission, components with teeth, etc., can solve the problems of complex synchronizer structure, complex shift structure, limited number of gears, etc., to increase shift stability The effect of high reliability, easy manufacturing, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

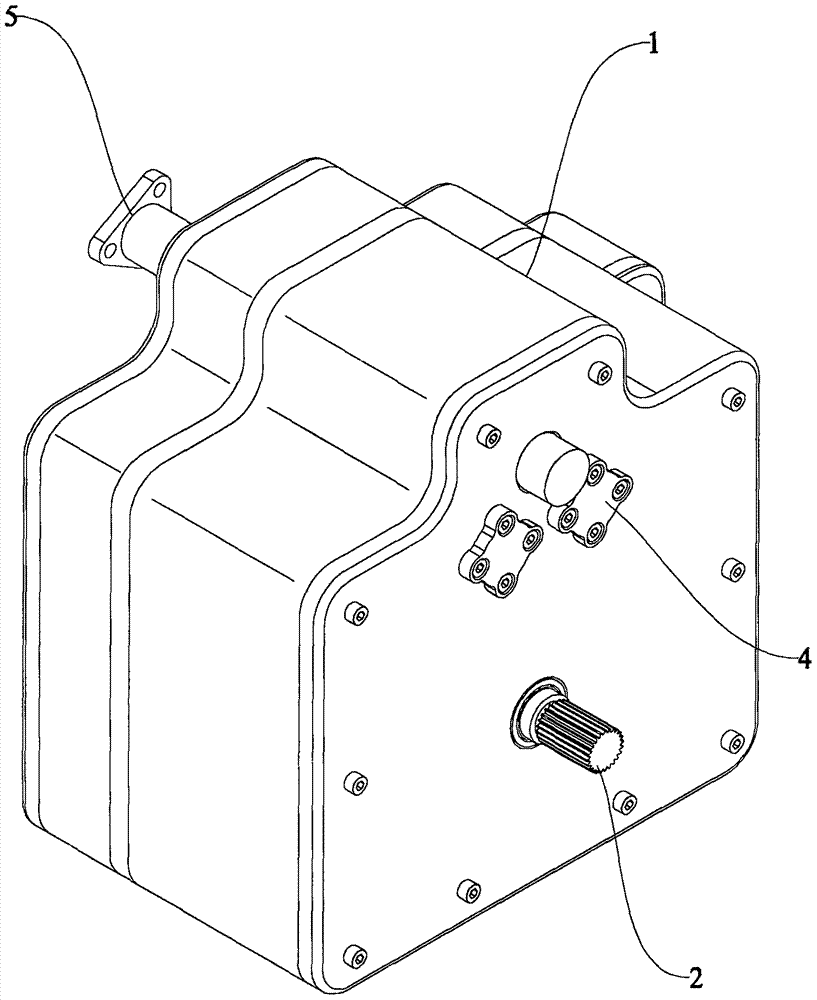

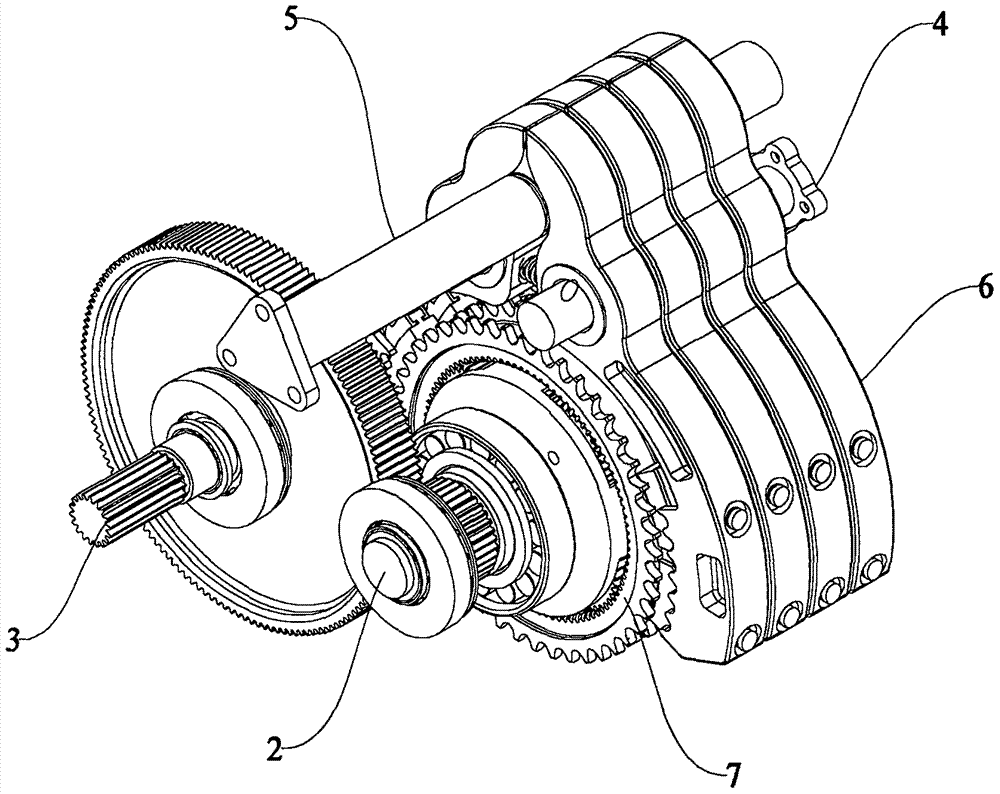

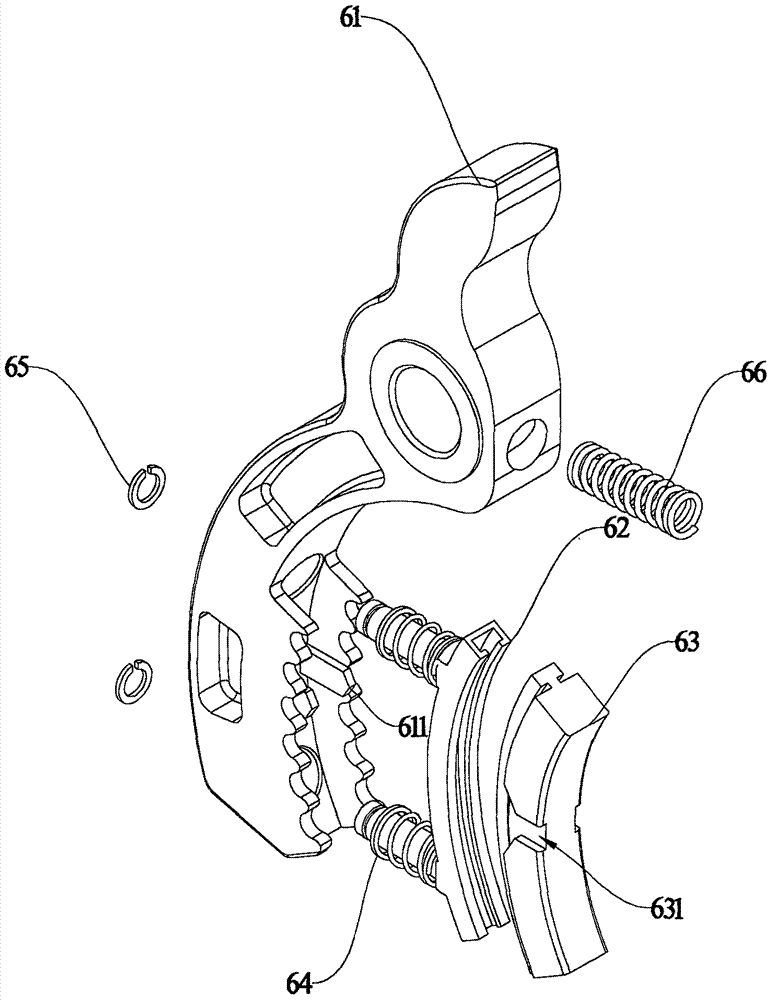

[0026] Such as Figure 1-11 As shown, an embodiment of the present invention includes a housing 1, an input shaft 2, an output shaft 3, a caliper shaft 4, a shift lever 5, a caliper assembly 6 and a planet carrier assembly 7, and the input shaft 2 and the output shaft 3 are respectively Rotationally connected to the housing 1, and the input shaft 2 drives the output shaft 3 to rotate. The planet carrier assembly 7 is arranged outside the input shaft 2 to control the speed of the input shaft 2. The caliper shaft 4 is fixed on the housing. The caliper assembly It is connected with the caliper shaft 4 in 6 rotations. specific:

[0027] The planetary carrier assembly 7 includes a planetary carrier 71, a fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com