Sliding isolation device with high-ductility concrete composite masonry structure, and construction method thereof

A high-ductility concrete and masonry structure technology, applied in the direction of basic structure engineering, protective devices, building components, etc., can solve the problems of poor earthquake resistance, etc., and achieve the effects of simple construction, enhanced restraint, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

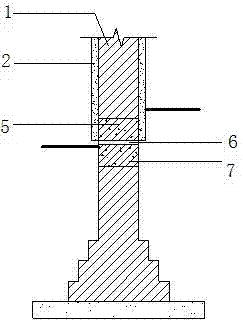

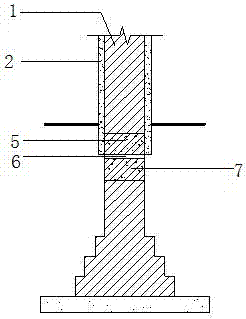

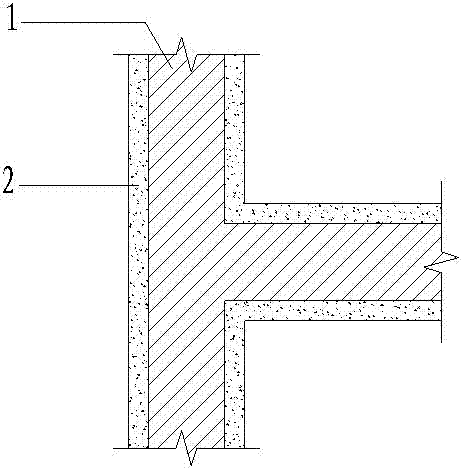

[0042] This embodiment provides a slip isolation device for a high ductility concrete composite masonry structure, such as figure 1 and figure 2 , image 3 , Figure 4 As shown, the bottom of the masonry wall 1 including the masonry wall 1 is provided with an upper geosphere beam 5 and a lower geosphere beam 7, and the lower geosphere beam 7 is provided with a seismic isolation layer 6, and the masonry wall 1 above the seismic isolation layer 6 Apply high ductility concrete surface layer 2 on both sides of the outer surface. The shock-isolation layer 6 is laid linoleum or graphene between the upper geosphere beam 5 and the lower geosphere beam 7 . The masonry wall 1 is a newly built brick masonry wall or block masonry wall, and the thickness of the high ductility concrete surface layer 2 plastered on the surface of the wall is 10-30 mm. The section width of the upper geosphere beam 5 and the lower geosphere beam 7 is the thickness of the wall, and the height is 240-300mm,...

Embodiment 2

[0050] This embodiment provides a kind of slip isolation device of reinforced mesh high ductility concrete composite masonry structure, such as Figure 5 and Figure 6 As shown, it includes a masonry wall 1 and a steel mesh bound on the surface of the masonry wall 1. The bottom of the masonry wall 1 is provided with an upper geosphere beam 5 and a lower geosphere beam 7, and the lower geosphere beam 7 is provided with a seismic isolation layer. 6. The outer surface of the masonry wall 1 above the seismic isolation layer 6 is double-sidedly pressed and plastered with the surface layer 2 . The shock-isolation layer 6 is laid linoleum or graphene between the upper geosphere beam 5 and the lower geosphere beam 7 . Such as Figure 7 , Figure 8 and Figure 9 As shown, the steel mesh is composed of vertical steel bars 3, horizontal steel bars 8 and wall-penetrating steel bars 4, and several vertical steel bars 3 and horizontal steel bars 8 are vertically intersected and bound on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com