A shaft construction method used as an underground three-dimensional garage

A construction method and technology of a three-dimensional garage, which are applied to buildings, buildings, building types, etc. where cars are parked, can solve problems such as affecting the construction progress, shaft wall deflection, and difficulty in lowering the shaft wall, so as to shorten the excavation time and reduce the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

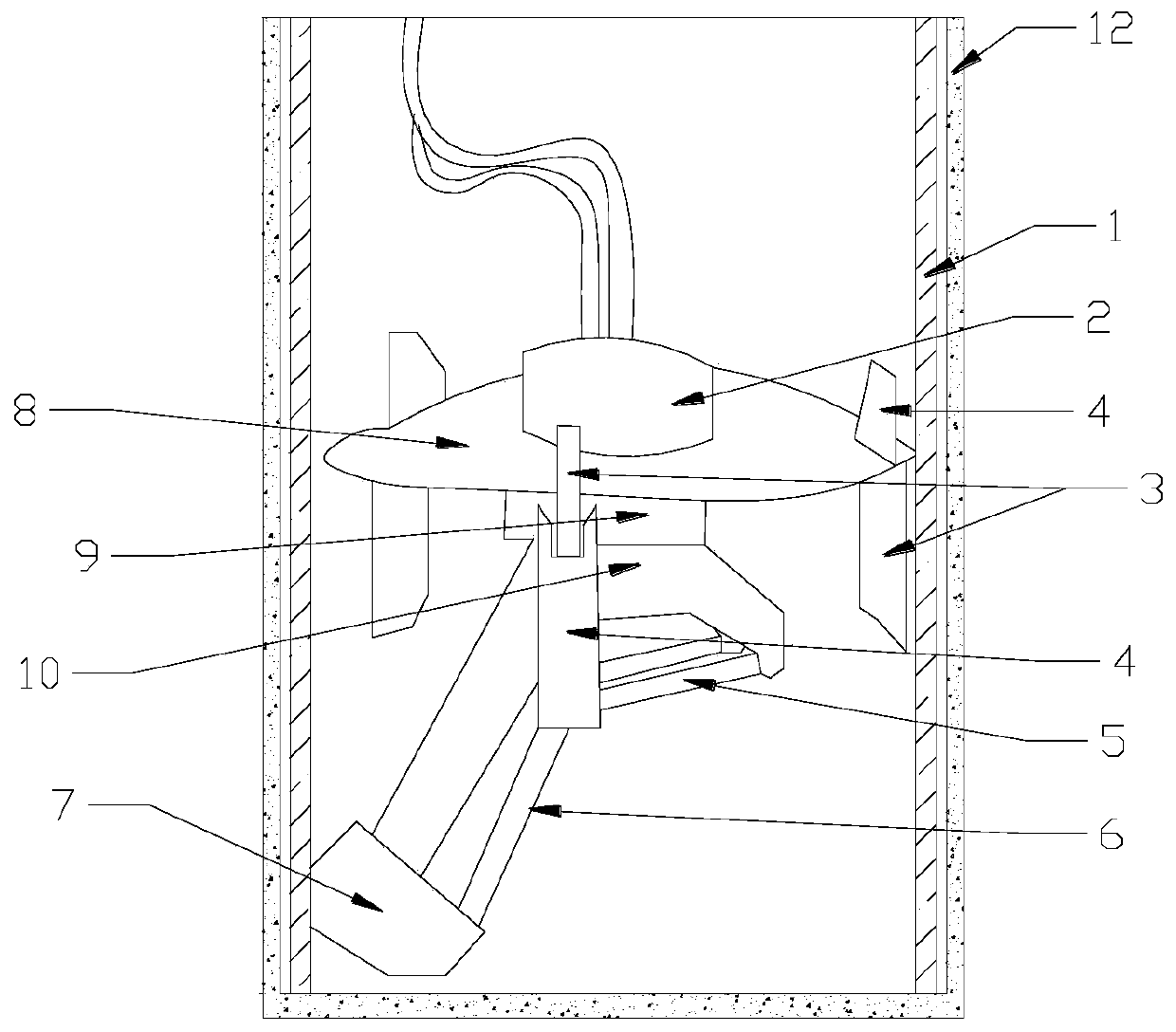

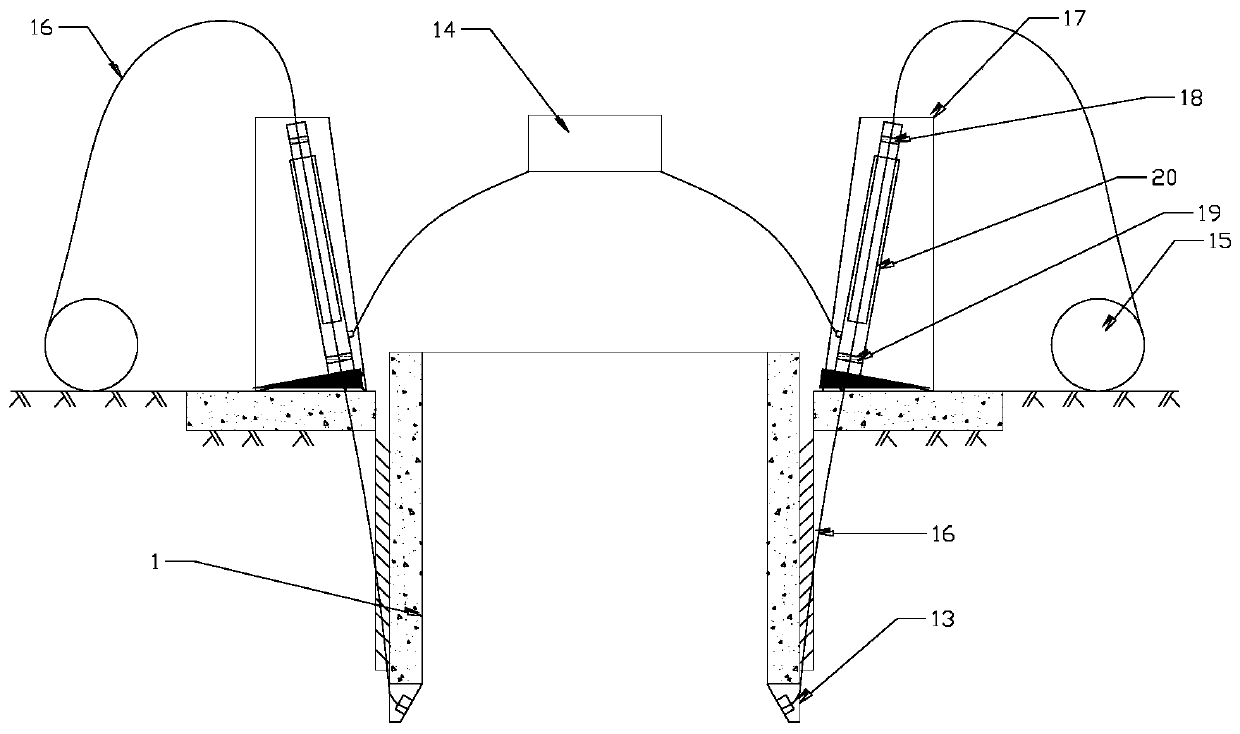

[0037] In order to explain the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and drawings. Similar components in the drawings are denoted by the same reference numerals. Those skilled in the art should understand that the content described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0038] Because the construction site area in urban areas is severely restricted, the use of vertical shafts to construct underground three-dimensional garages can effectively use the three-dimensional space of the urban vacant land and improve land utilization. However, the use of vertical shafts to build underground three-dimensional garages requires shaft excavation. The method of constructing a shaft for an underground three-dimensional garage includes the following steps:

[0039] 1) Excavation of the first section of the shaft.

[0040] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com