Shield construction system and shield construction method

A technology of shield and components, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of low construction efficiency, shield tunneling and hoisting cannot be carried out at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

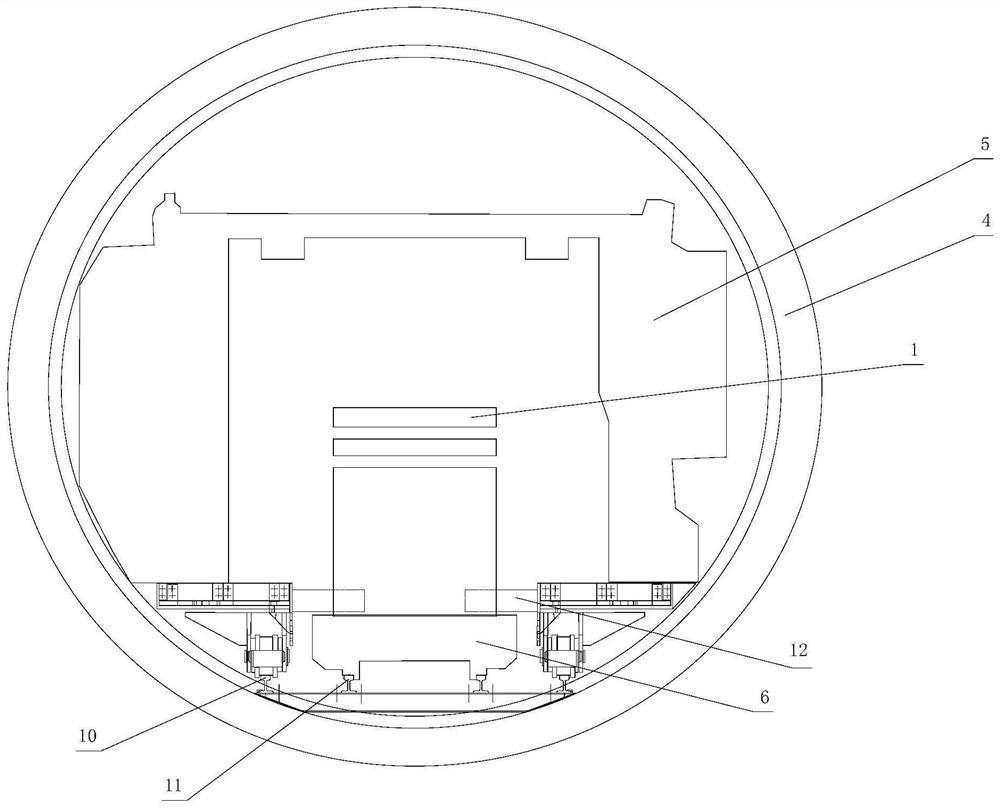

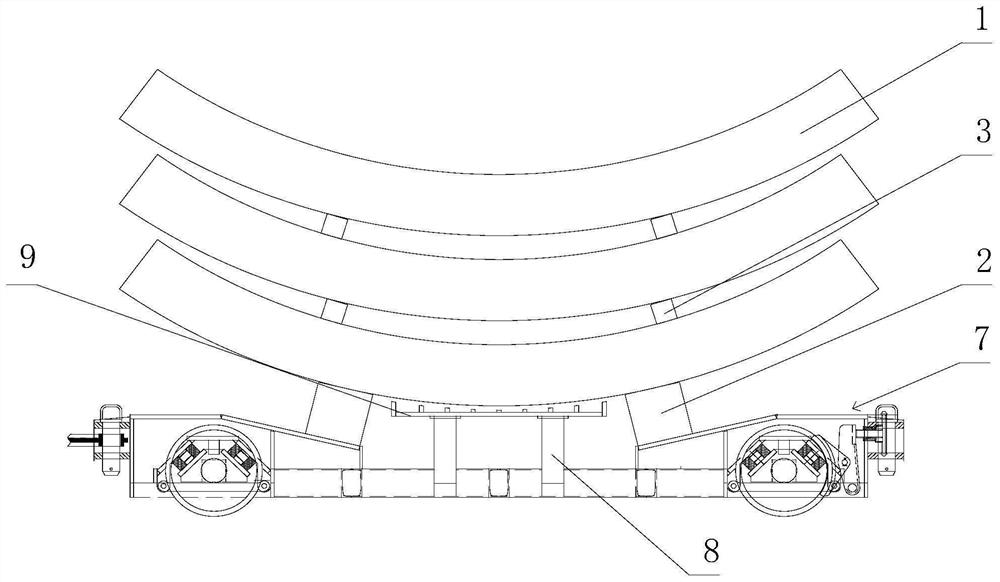

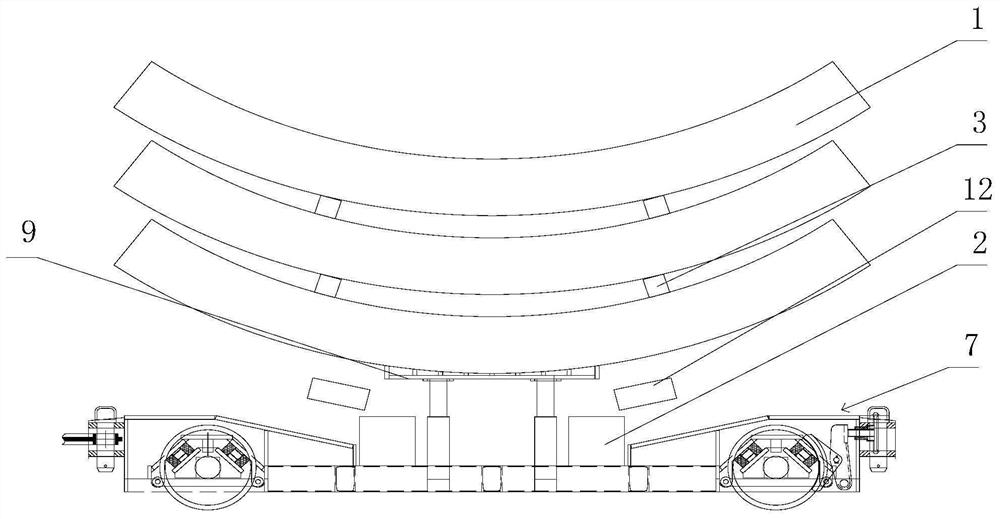

[0032]Such asFigure 1 - Figure 5As shown in the present embodiment, a shield construction system includes a trolley 5 and a tunnel battery vehicle 6, and there are two trust rails 10 and tunnel according to the tunnel 4, and the tunnel battery track 11 is located in two tables. Between the vehicle orbital 10, the trolley 5 is disposed on two trolley tracks 10, and the tunnel battery vehicle 6 is disposed on the tunnel battery trail 11, and the front of the trolley 5 is open, and the front side of the trolley 5 has an opening, and also The first square wood unit, a top support unit, and a cantilever unit are included, and the first square wood unit is disposed on the tablet 7 of the tunnel battery vehicle 6, and the first square wood unit includes two first square wood 2, two first squares. The wood 2 is distributed in the front-rear direction and can support the tubular set, and the top support unit is disposed between two first square wood 2, and the top support unit includes the l...

Embodiment 2

[0042]The present embodiment has been further defined on the basis of the first embodiment, and the tubular group includes two and more tubular sheets 1, two and more tubes 1 longitudinal distribution, adjacent two tubes The sheet 1, and the lower tubes 1 are placed on two second square wood 3, and the two second square wood 3 supports the upper tubular sheet 1, in particular, the number of tubes 1 contained in the tube set is performed according to the actual situation. Set, for example, a shield machine having an outer diameter of 6.28 m, the outer diameter of the tube 1 is 6m, the inner diameter is 5.4m, width is 1.2m, in the specific use, set the flat plate 7 on the tunnel battery car 6, first square wood unit Both the cantilever unit, the top support unit, and the tubular sets are two, the plate 7, the first square wood unit, the cantilever unit, the top support unit, and the tube set one by one.

Embodiment 3

[0044]The present embodiment has been further defined on the basis of the first embodiment, and the present embodiment provides a shield construction method, using a shield construction system, including the following steps:

[0045]A. Place the tube set on the first square wood unit;

[0046]B, use tunnel battery cars 6 transport the tubular port from the front side of the trolley 5;

[0047]C, start the top support unit, bring the tube set from the first square wood 2, remove the first square wood 2;

[0048]D, the tunnel battery car 6 continues to move until the tube set is located above the cantilever unit;

[0049]E, the top support unit drops, the tube set is placed on the cantilever unit, and the tunnel battery car moves from the trolley 5 to the outsoile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com