Telescopic spiling with automatic adjusting and centralizing functions

An automatic adjustment and telescopic technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of increased project cost, low economic benefit, delay in construction period, etc., to save project cost, significant economic benefit and time saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

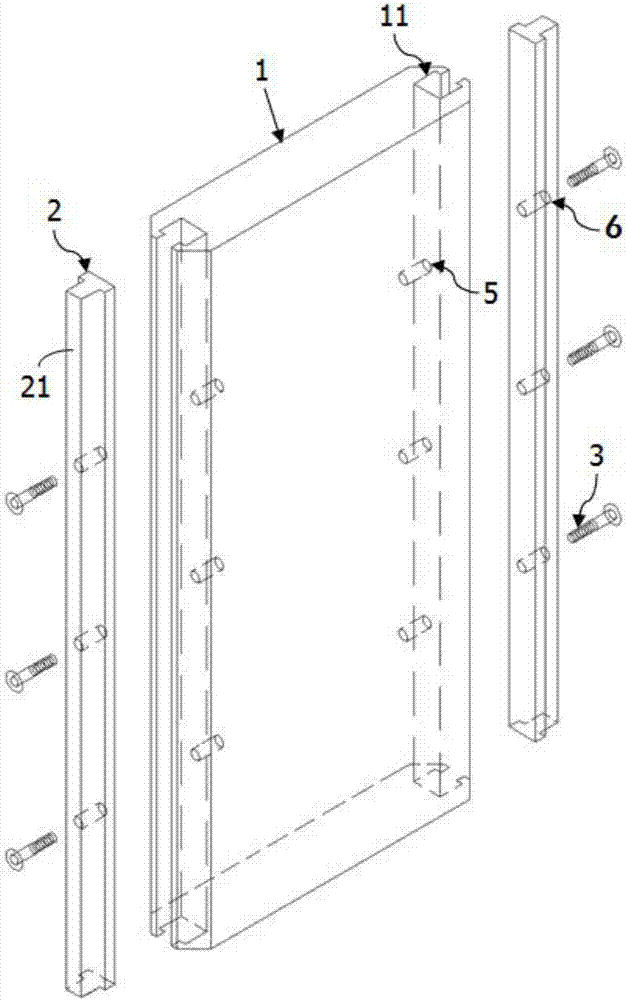

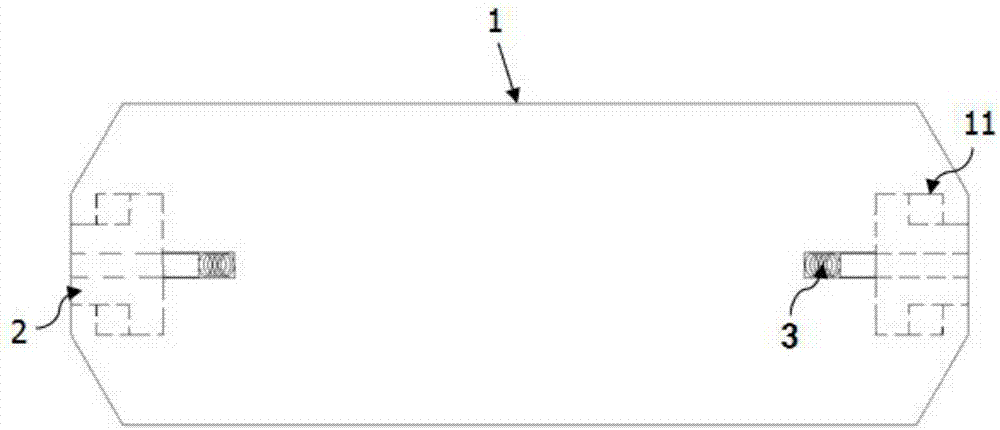

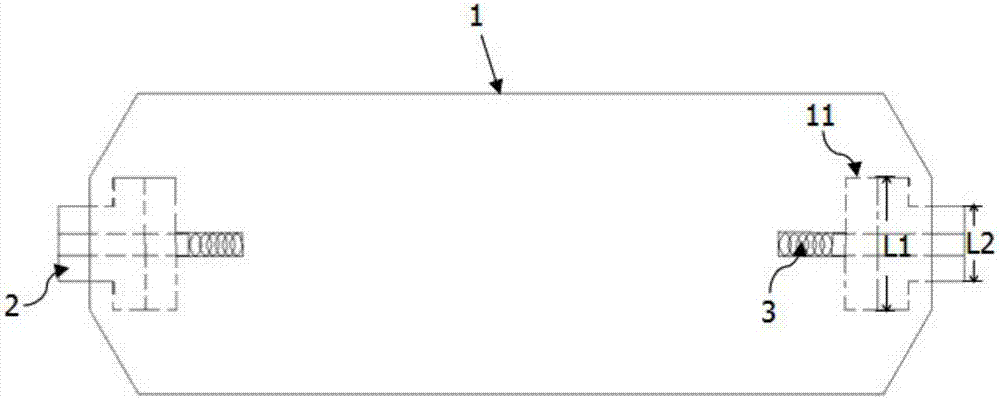

[0022] combine Figure 1 to Figure 3 Shown is a specific embodiment of a retractable sheet pile with automatic adjustment and straightening function of the present invention, which includes a sheet pile body 1 , and telescopic sockets arranged on the left and right sides of the sheet pile body 1 . mechanism. Each telescopic mechanism includes a telescopic plate 2, an elastic member 3 arranged between the telescopic plate 2 and the sheet pile body 1, and the elastic member 3 enables the telescopic plate 2 to move away from the telescopic plate in the left and right direction. Move in the direction of the sheet pile body 1 described above, that is, the telescopic plate 2 is ejected outward relative to the sheet pile body 1 . The length of the expansion plate 2 extends along the longitudinal direction of the sheet pile body 1 , and the length of the expansion plate 2 is equal to the longitudinal height of the sheet pile body 1 . Not shown in the figure, preferably, the lower pa...

Embodiment 2

[0028] Embodiment 2: In this embodiment, combining Figure 4As shown, the difference from Embodiment 1 is that each of the expansion plates 2 is provided with three guide rods 4 extending in the left and right directions, and correspondingly, each of the expansion plates 2 is longitudinally distributed with guide rods 4 for the guide rods. The positions of the second positioning holes 7 where the rods 4 are inserted are projected on the corresponding upper / lower end surfaces of the telescopic plate 2 are misaligned, that is, they are not on a straight longitudinal line. The elastic member 3 is provided between the bottom of each second positioning hole 7 and its corresponding guide rod 4, and in addition, the corresponding guide rod 4 and the second positioning hole 7 are respectively provided with matching limiting bosses. and a tightening part to slidably restrict the guide rod 4 in the second positioning hole (7) in the left and right direction, and each of the second posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com