Color changing piece

A technology of color-changing film and color-changing layer, which is applied in the field of color-changing film, to achieve the effect of simple structure, easy production and improvement of color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

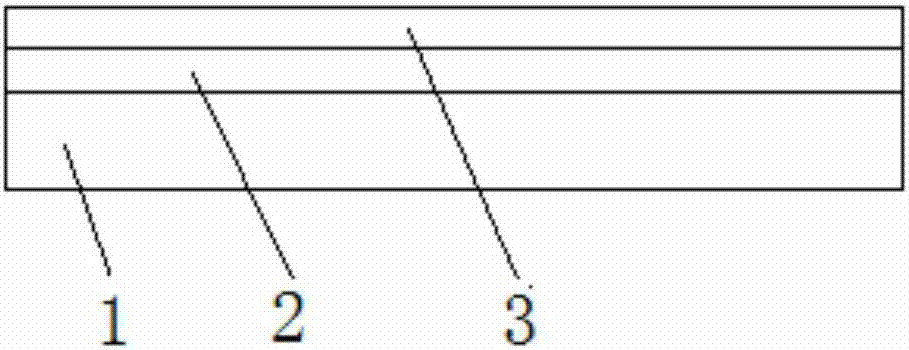

Image

Examples

Embodiment 1

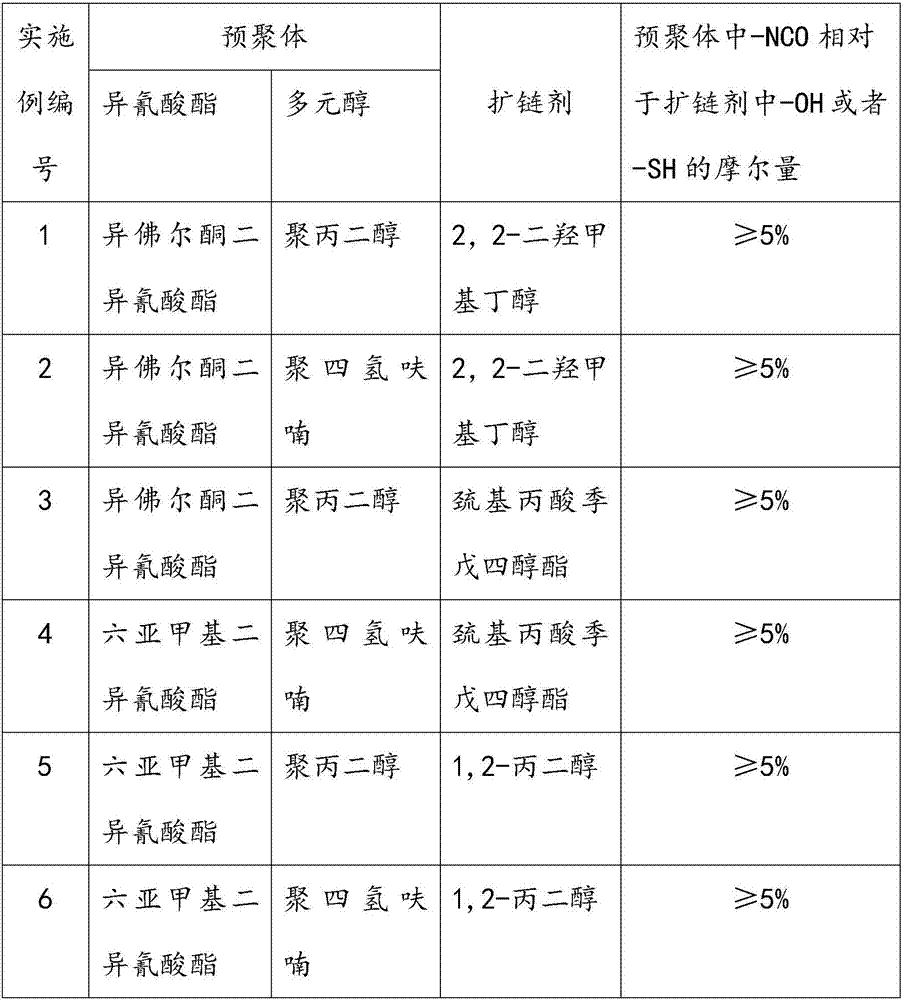

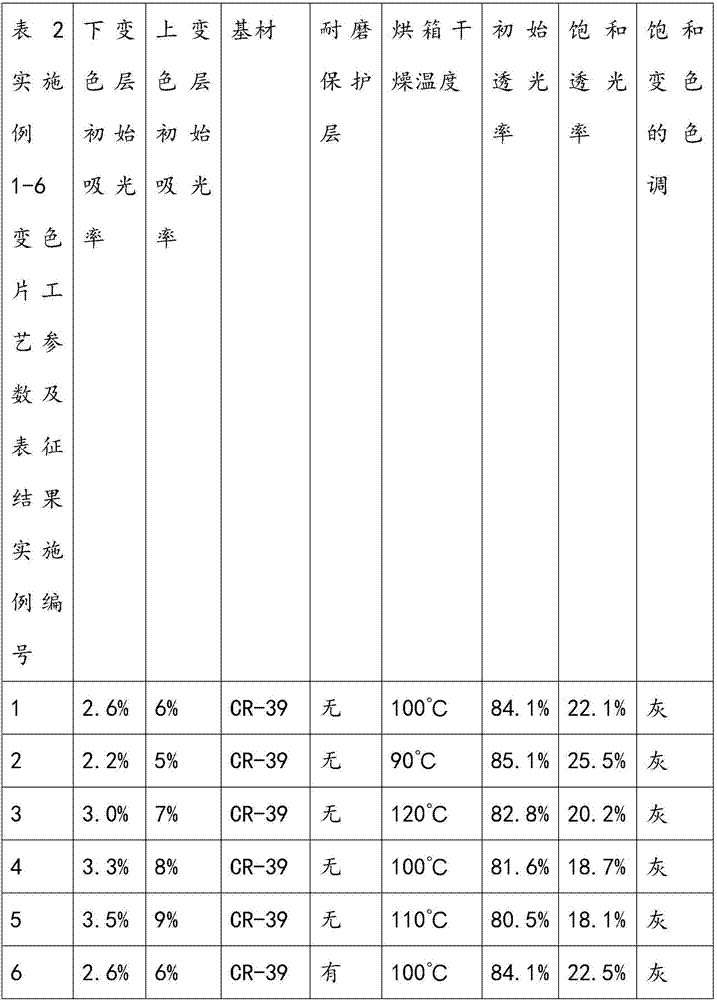

[0033] Embodiment 1 (the percentage is a mass percentage, and the ratio is a mass ratio):

[0034] The CR-39 disc was used as the base material, soaked in 5% potassium hydroxide aqueous solution at 60 degrees Celsius for 10 minutes for cleaning, then washed with soapy water and deionized water, and dried with compressed air. The substrate is cleaned with a plasma cleaning machine: under an oxygen flow of 50 ml / min and a pressure of less than 0.5 mm Hg, it is treated for 60 seconds. Then spin-coat the coating solution of the lower color-changing layer on the substrate, and control the rotation speed to make the coating thickness 18 μm. After spin-coating to form a film, the wafer is placed in a nitrogen oven at 100 degrees Celsius to dry for 4 hours. Take out the wafer, and after cooling, spin-coat the second photochromic layer coating solution with a coating thickness of 12 μm. After spin-coating to form a film, put the wafer in a nitrogen oven at 100 degrees Celsius and dry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com