Improved pipe clamping device for industrial robot

An industrial robot and clamping device technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of difficult control of the center of gravity of pipe fittings, insufficient stability of pipe clamping, and complex design structures, etc., to achieve clamping The effect of tightening safety and reliability, reducing quantity, and working safely and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

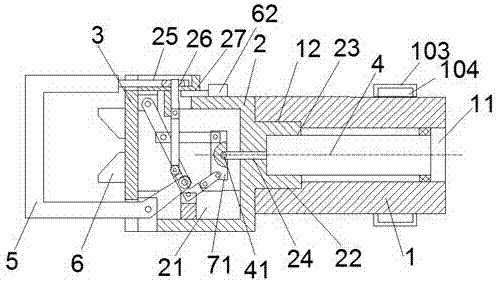

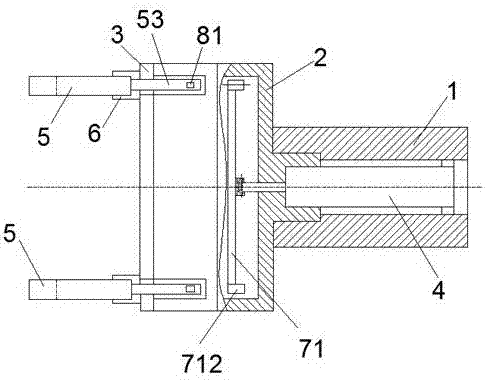

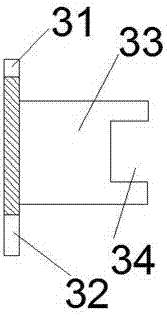

[0032] Such as Figure 1-Figure 12As shown, a pipe fitting clamping device for an improved industrial robot of the present invention includes a joint 1 connected to the mechanical arm of the industrial robot, and a joint 1 fixed on the left end of the joint 1 and provided with an opening facing left. The upper surface of the cavity 21 is provided with a rectangular groove 25, and on the right side of the second cavity 21 directly below the rectangular groove 25, a seat body 2 of a narrow and long through groove 27 is provided, and the seat body in the middle of the rectangular groove 25 2 is provided with a rectangular hole 26 in the up and down direction, and a cover plate 3 fixedly installed on the left end of the seat body 2 and extending rightward into the second cavity 21, two sets of connecting rod groups, and a driving cylinder 4, and two U-shaped mechanical claws 5, and an iron stop assembly installed on the upper surface of the seat body 2 on the right side of the nar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com