Manufacturing method of injection molded part and injection molded part

A manufacturing method and technology for injection molded parts, which can be used in coating and other directions to solve the problems of overflowing glue, flushing of embedded nuts, and low tensile strength and torsional strength of embedded nuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Please refer to Figure 1~4 , a preferred embodiment of the present invention provides a method for manufacturing an injection molded part 100, which includes the following steps:

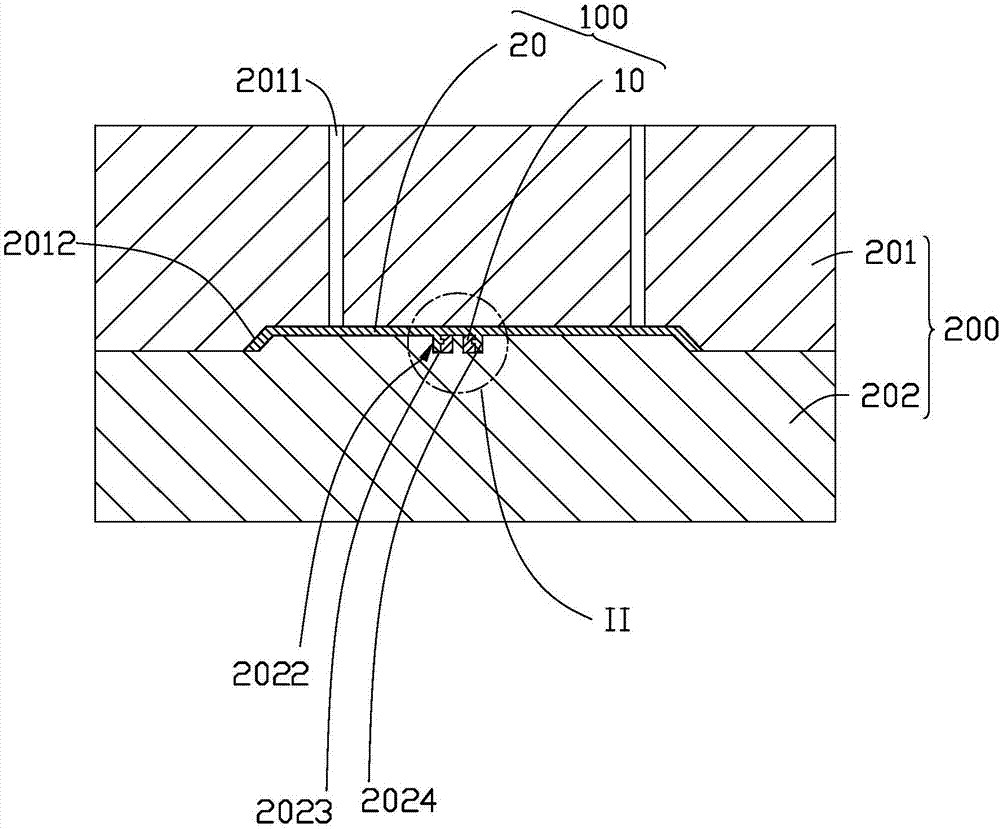

[0054] Step S1, see Figure 1~2 , providing an injection mold 200 .

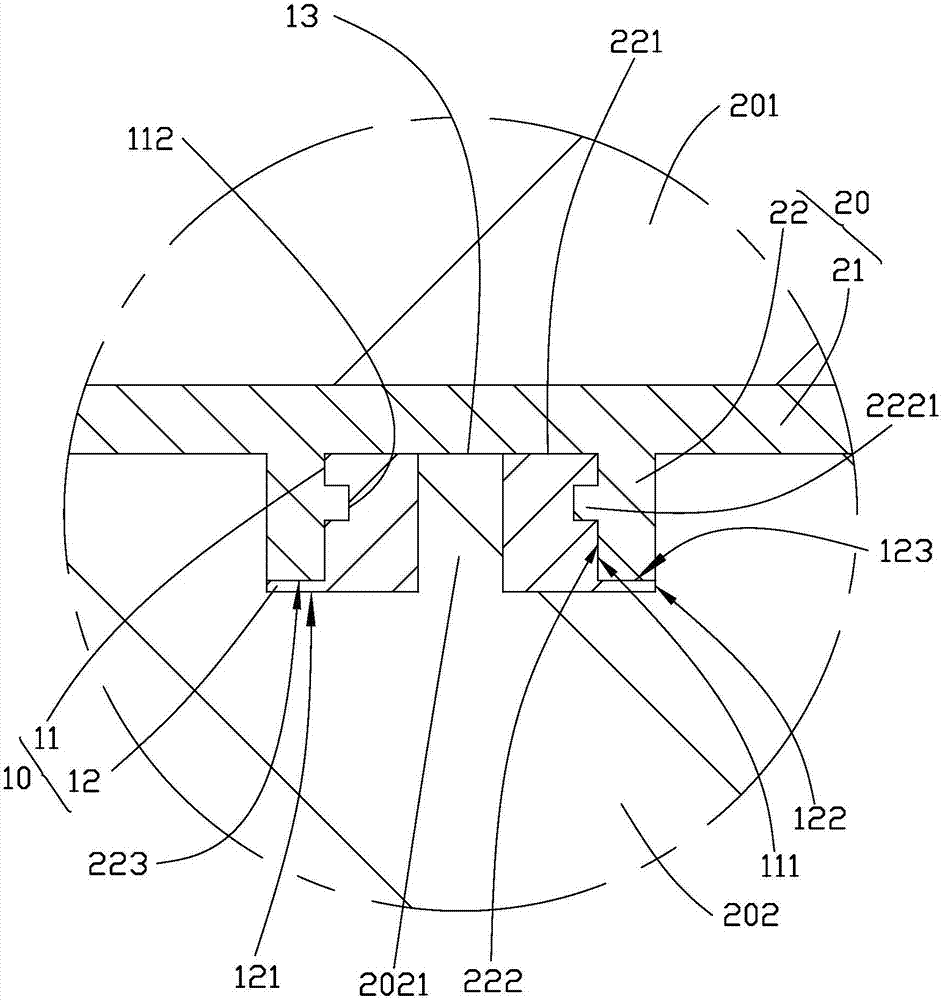

[0055] The injection mold 200 includes an upper mold 201 and a lower mold 202 . The upper mold 201 is provided with a plurality of gates 2011 and a first cavity 2012 . The lower mold 202 is provided with at least one positioning column 2021 and at least one second cavity 2022 . Each second mold cavity 2022 is disposed around a positioning column 2021 . The second mold cavity 2022 is substantially an annular groove.

[0056] The second mold cavity 2022 has a bottom surface 2023 and a side surface 2024 vertically connected to the bottom surface 2023 and opposite to the positioning post 2021 .

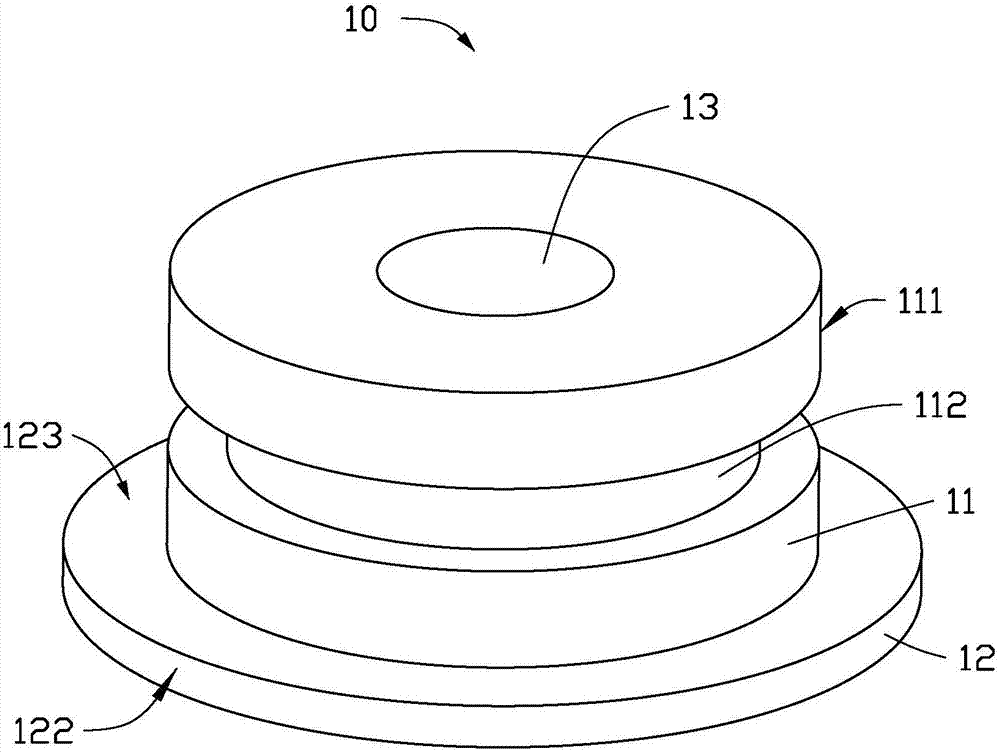

[0057] Step S2, see further image 3 , at least one inner nut 10 is provided.

[0058] The embedded nut 10 includes a body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com