Quick clamp for electric vehicle hub

An electric vehicle and wheel hub technology, which is applied in the field of electric wheel hub quick fixtures, can solve the problems of increasing the processing cost of electric vehicles, the labor intensity of workers, and the increase of labor costs, and achieves low labor intensity, simple structure, and low processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

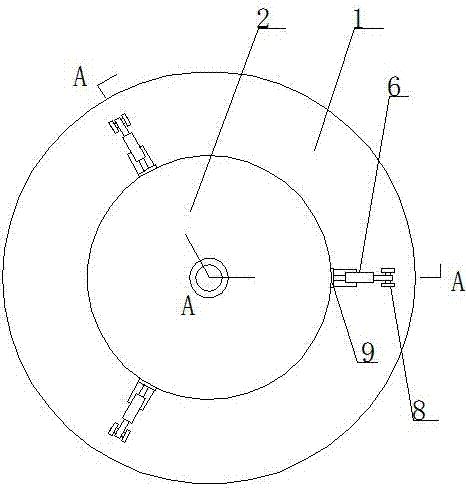

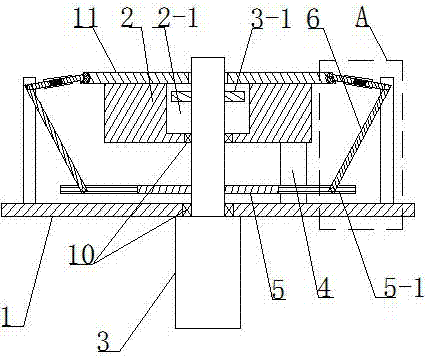

[0015] Such as figure 1 , figure 2 and image 3 As shown, a quick fixture for an electric wheel hub, the support platform 2 is a circular platform, and the support platform 2 is fixed with an outrigger 4 connected to the workbench 1, and there are three outriggers 4, which are evenly arranged. A vertically arranged clamping cylinder 3 is arranged directly below the support platform 2, and the piston rod of the clamping cylinder 3 is arranged vertically upward; the piston rod of the clamping cylinder 3 passes upward through the through hole 2 of the support platform 2- 1. A gear stand 3-1 is fixed on the upper end of the piston rod of the clamping oil cylinder 3; the diameter of the gear stand 3-1 is smaller than the diameter of the through hole 2-1. The cylinder body of the clamping oil cylinder 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com