Working method of waste material clearing device

A technology for cleaning devices and working methods, applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the processing quality of the next workpiece, inconvenient cleaning of waste materials, etc., and achieve lower temperature, simple structure, easy to place and take take advantage of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

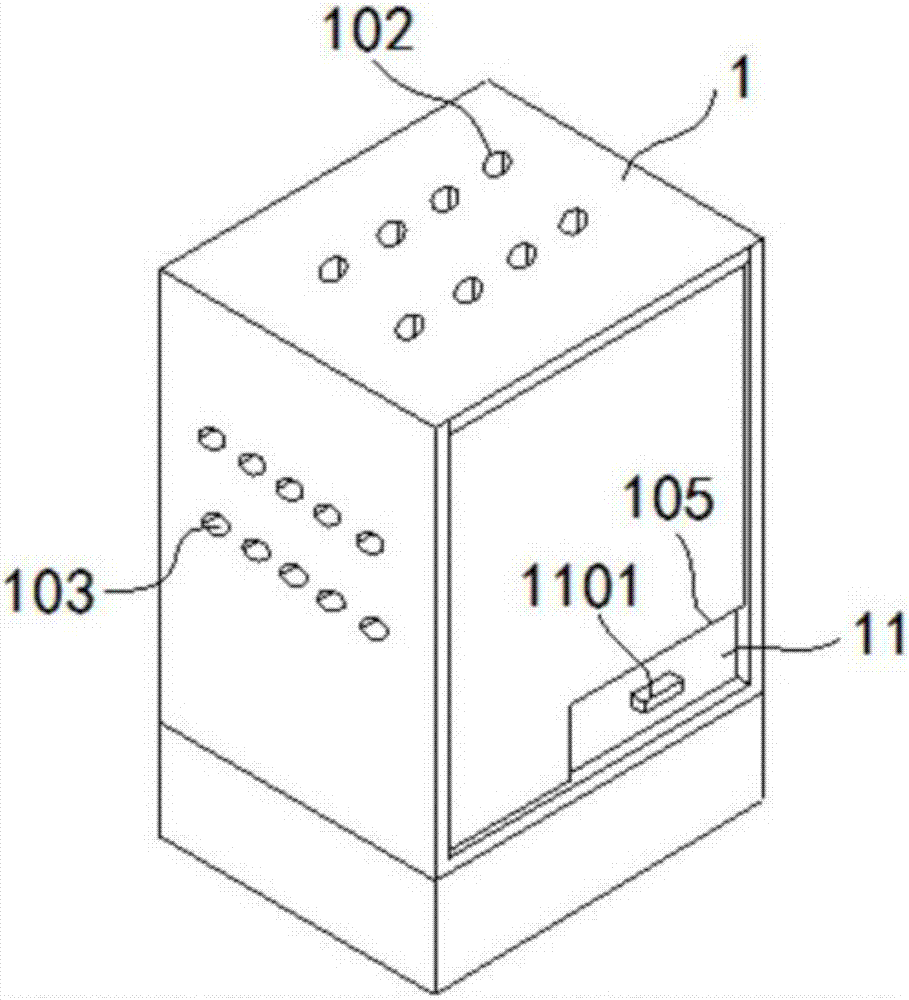

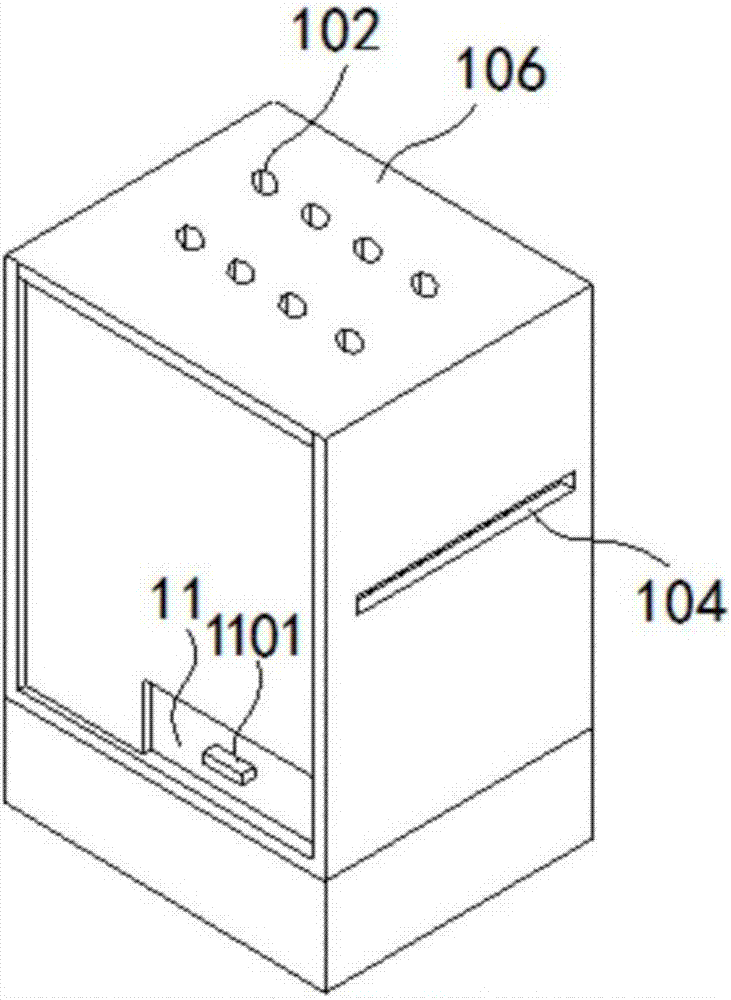

[0028] Such as figure 1 , figure 2 , image 3 As shown, the waste cleaning device for laser cutting equipment of the present invention includes:

[0029] A protective box 1, the protective box 1 is installed on the bracket, the top of the protective box 1 is provided with a sliding device 101, the inner side wall of the protective box 1 is provided with a long groove 104, the protective box A notch 105 is formed on the front side wall of the body 1 . The upper cover of the protective box 1 is provided with several air inlet holes 102 , and the side wall of the protective box 1 is provided with several air outlet holes 103 . The upper cover 106 of the protective box 1 is a reversible structure, and the upper cover 106 is hinged on an inner side wall of the protective box 1 through a second hinge 107 .

[0030] Processing platform 2, the processing platform 2 is arranged in the protective box 1, one side of the processing platform 2 is hinged on the inner side wall of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com