Refrigerator inner container manufacturing method with glue application being conducted before riveting

A technology of freezer liner and preparation steps, which is applied in the field of freezer liner production line, which can solve problems such as the lack of a fully automated freezer liner production line, and achieve the effects of facilitating equipment layout, reducing mutual interference, and good riveting production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings.

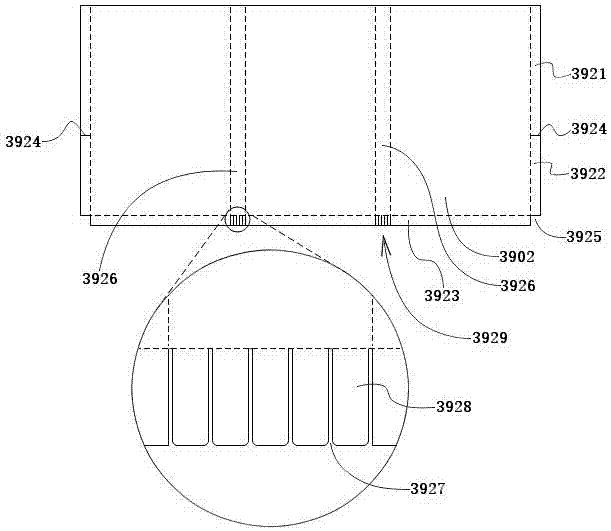

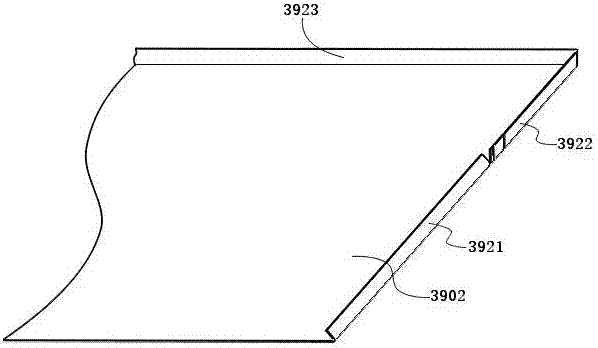

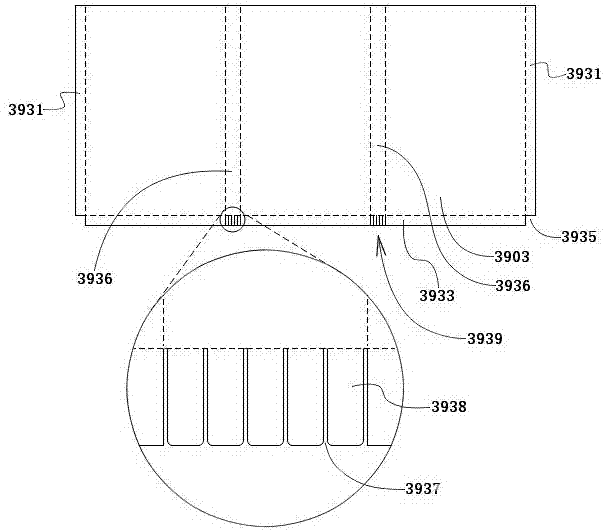

[0057] A method for preparing a freezer liner according to the present invention, comprising the steps of preparing a U-shaped large enclosure, a preparation of a U-shaped small enclosure, a preparation of a Z-shaped bottom panel, a riveting step of a mouth-shaped enclosure, a step of glueing corners, and a The step of riveting the bottom plate, the step of punching the side and the step of gluing the riveting line. Wherein, the step of preparing the U-shaped large enclosure is used to prepare the patterned aluminum plate into a U-shaped large enclosure. The U-shaped small enclosure preparation step is used to prepare the patterned aluminum plate into a U-shaped small enclosure. The Z-shaped bottom plate preparation step is used to prepare the patterned aluminum plate into a Z-shaped bottom plate. The riveting step of the mouth-shaped coaming is used to riv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com