Grinding mill and ceramic preparation method

A mill and locking mechanism technology, applied in the direction of grain processing, etc., can solve problems such as difficulty in ensuring uniform crushing of materials, uneven viscosity, softness and hardness, and influence on stirring effect, so as to avoid excessive vibration amplitude, save energy, and grind The effect of grinding effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1:

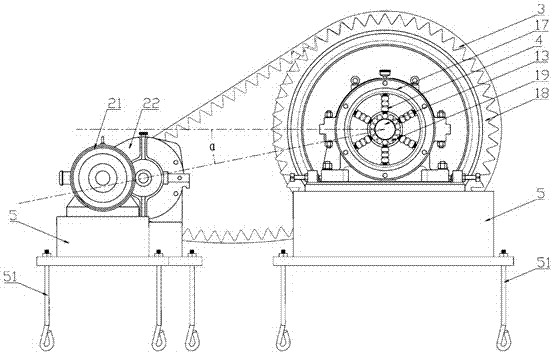

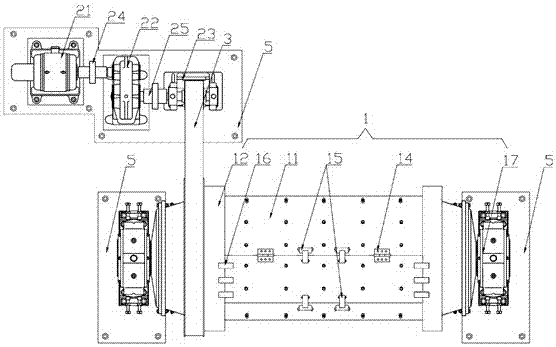

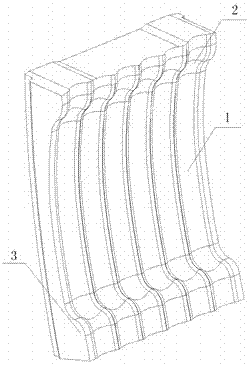

[0033] like Figure 1-2 , a pulverizing mill, including a hollow cylindrical rotating cylinder 1, a motor 21, a base 5 with a ground lock 51 at the bottom, and a material gate 11 on the rotating cylinder 1. The two ends of the material door 11 are flush with each other, and the material door 11 is extended to the outside relative to the rotating drum 1 around the rotating shaft 14. In the closed state, the locking mechanism provided at the corresponding interface between the material door 11 and the rotating drum 1 locks both; in this embodiment , the locking mechanism adopts the locking buckles 15 arranged on the two ends of one side of the rotating shaft 14 and the corresponding interface between the material door 11 and the rotating drum 1, and the locking pair 15 arranged on the side wall 12 of the rotating drum 1 and the material door 11. Locked locking snaps 16 . This design can enhance the bonding strength between the material gate 11 and the wall ...

Example Embodiment

[0041] Embodiment 2:

[0042] like Figure 1-2 , a pulverizing mill, including a hollow cylindrical rotating cylinder 1, a motor 21, a base 5 with a ground lock 51 at the bottom, and a material gate 11 on the rotating cylinder 1. The two ends of the material door 11 are flush with each other, and the material door 11 is extended to the outside relative to the rotating drum 1 around the rotating shaft 14. In the closed state, the locking mechanism provided at the corresponding interface between the material door 11 and the rotating drum 1 locks both; in this embodiment , the locking mechanism adopts the locking buckles 15 arranged on the two ends of one side of the rotating shaft 14 and the corresponding interface between the material door 11 and the rotating drum 1, and the locking pair 15 arranged on the side wall 12 of the rotating drum 1 and the material door 11. Locked locking snaps 16 . This design can enhance the bonding strength between the material gate 11 and the wa...

Example Embodiment

[0047] Embodiment three:

[0048] A method for preparing ceramics using a pulverizing mill, comprising the following processes:

[0049] Weigh the raw materials according to the specific gravity: 5-10 parts of clay, 85-88 parts of quartz, 1-5 parts of CaO and K2O, an appropriate amount of water and an appropriate amount of binder; mix them evenly, place them in a pulverizer and stir for 20-30 After hours, the frequency conversion control system controls the motor to drive the pulverizing mill, and sinters the mixed material after stirring to obtain the ceramic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com