Material mixing device for inorganic chemical experiment

A material mixing and inorganic chemistry technology, applied in chemical/physical processes, mixers, mixing methods, etc., can solve the problems of inability to grind and pulverize materials, increase labor intensity of laboratory personnel, etc., achieve simple structure, reduce labor intensity, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

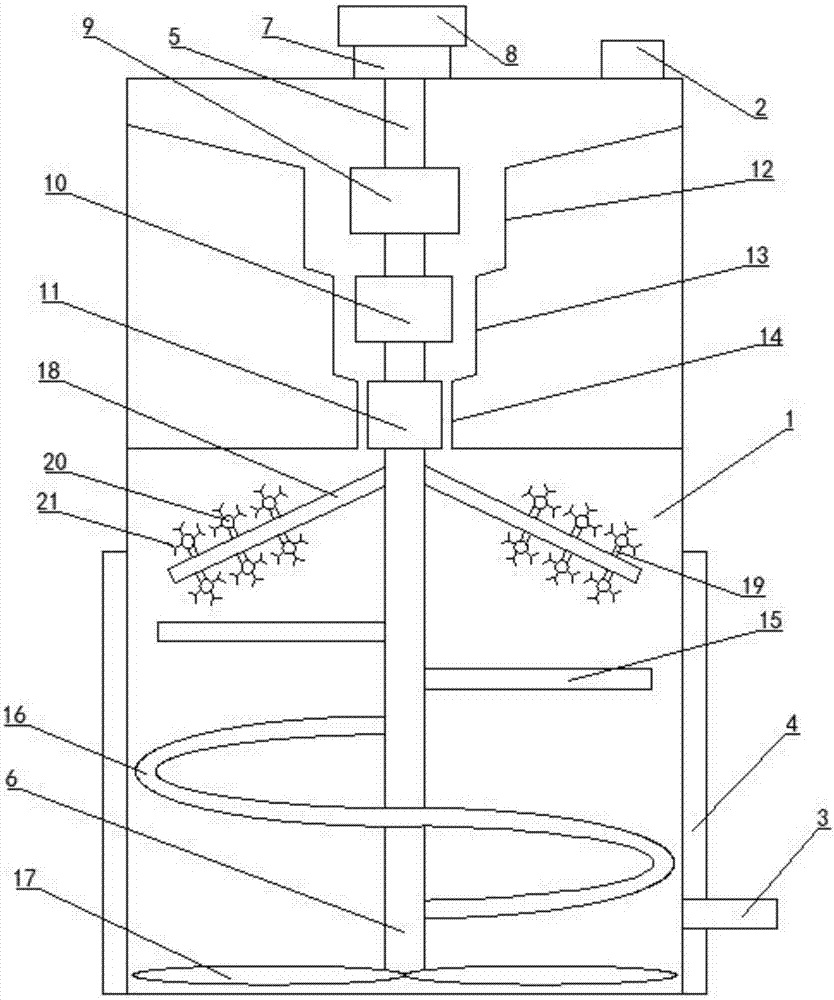

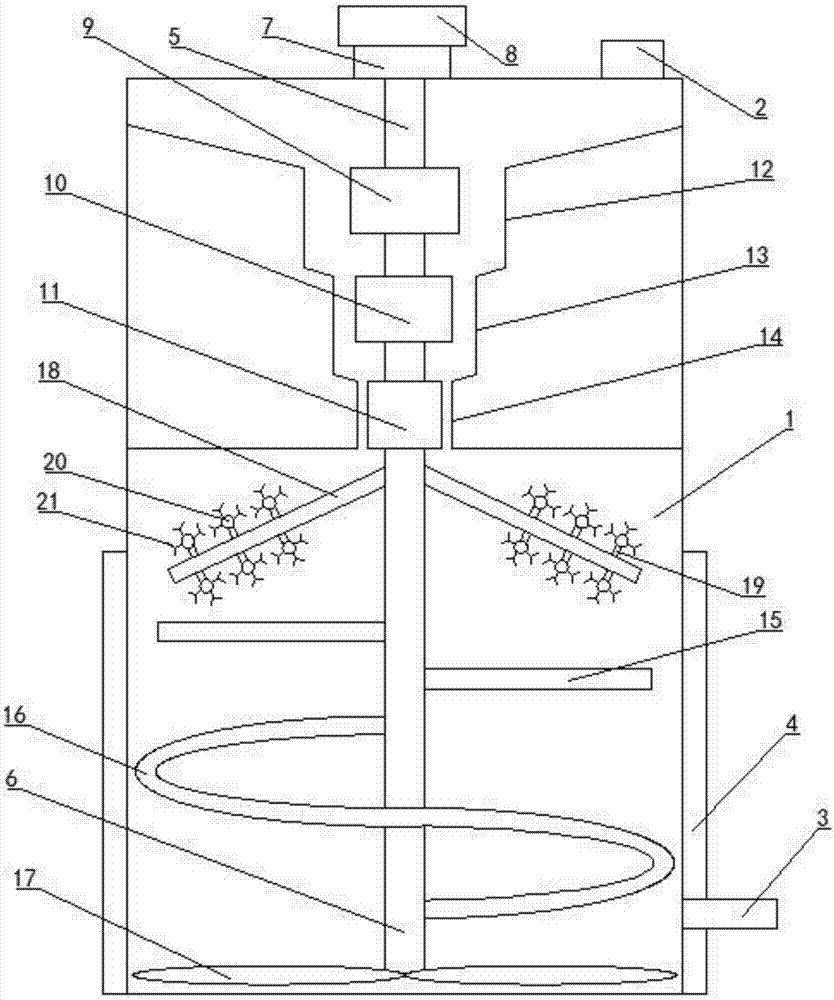

[0017] A material mixing device for inorganic chemistry experiments, such as figure 1 Shown, comprise mixing tank 1, be provided with stirring device in mixing tank 1, the top of mixing tank 1 is provided with feed inlet 2, the bottom of mixing tank 1 sidewall is provided with discharge port 3, mixing tank 1 is provided with a heating jacket 4 on the outer wall; the stirring device includes a first stirring shaft 5 on the upper part and a second stirring shaft 6 on the lower part, and the first stirring shaft 5 and the second stirring shaft 6 are of an integrated structure; the first stirring shaft The upper end of the shaft 5 runs through the top of the mixing tank 1, the upper end of the first stirring shaft 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com