Mud discharging system for sedimentation tank

A technology of mud system and sedimentation tank, which is applied in the direction of sedimentation separation, feeding/discharging device of sedimentation tank, chemical instruments and methods, etc., can solve problems such as energy waste, reduce the blind area of mud discharge, and improve the effect of mud discharge , Improve the effect of mud discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

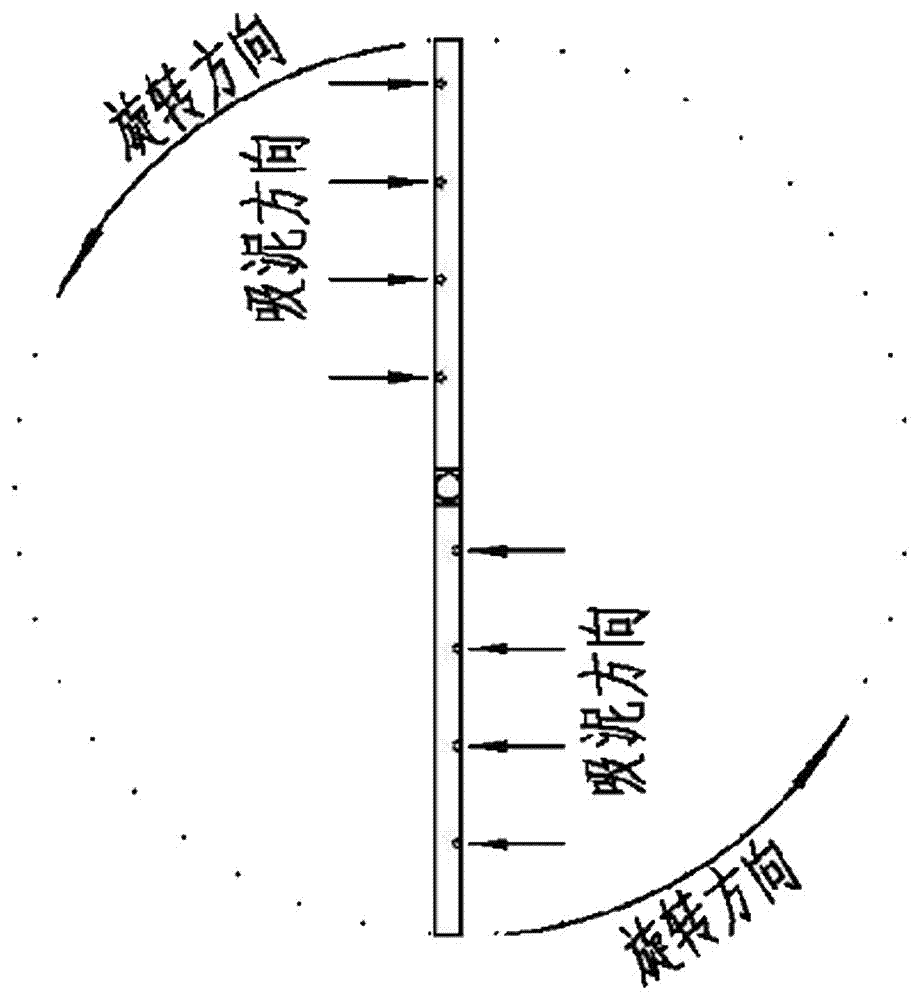

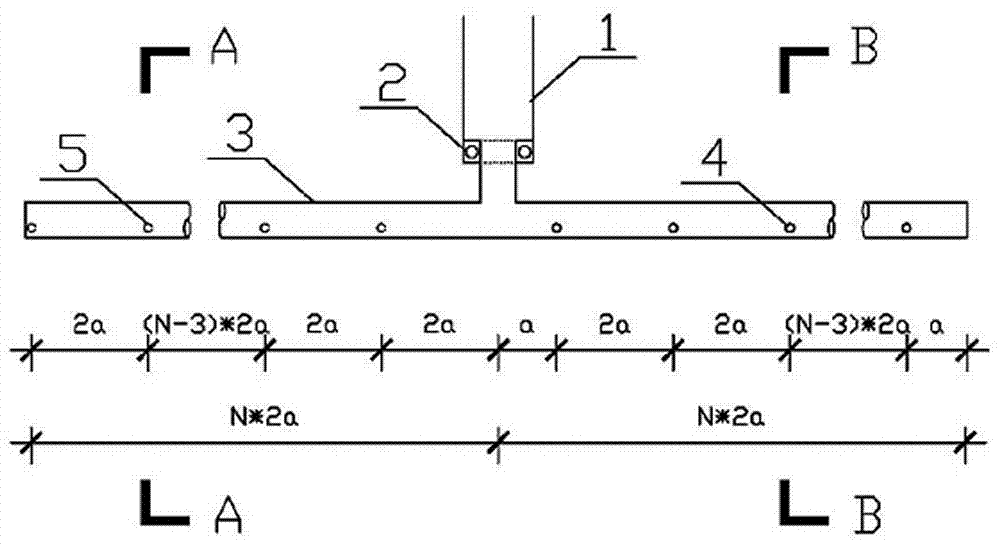

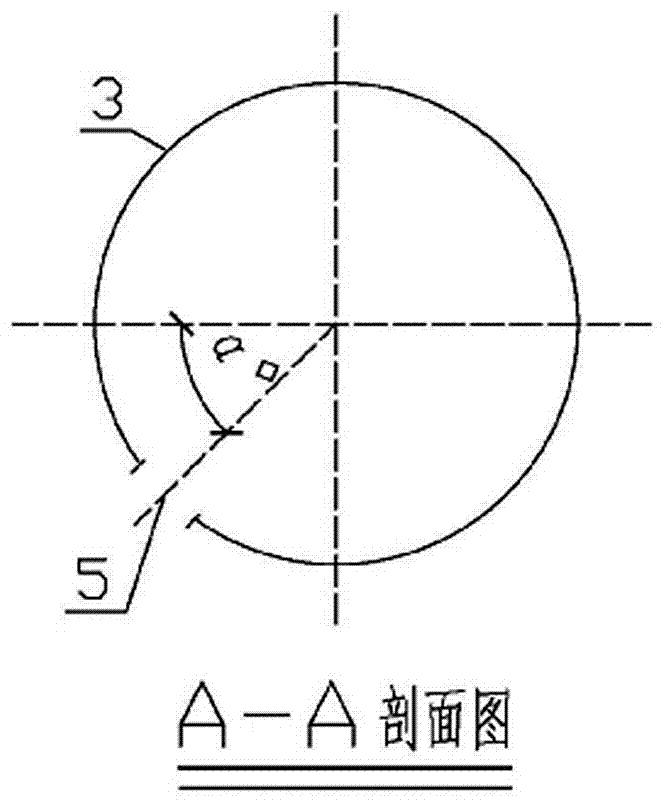

[0020] This embodiment of the present invention is a sludge discharge system for a sedimentation tank, which mainly includes a rotary sludge discharge device 3 with a self-rotating function, a sludge discharge main pipe 1 , a sludge discharge branch pipe 2 and a bearing 4 . Among them, the rotary mud discharge device 3 with self-rotation function includes a rotary tee, the middle section of which is opened upwards, and is connected with the branch pipe 2 through the bearing 4, so that the rotary mud discharge device 3 is located below the mud discharge branch pipe. Both sides of the rotating tee are respectively connected to the first perforated mud discharge pipe and the second perforated mud discharge pipe. The lengths of the first perforated mud discharge pipe and the second perforated mud discharge pipe are determined according to the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com