Automatic extrusion device

An extruder, automatic technology, used in brackets or dispensers, household appliances, sanitary equipment, etc., can solve problems such as taking up space, leakage of toothpaste, facial cleanser, increasing search time, etc., to reduce wear and friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

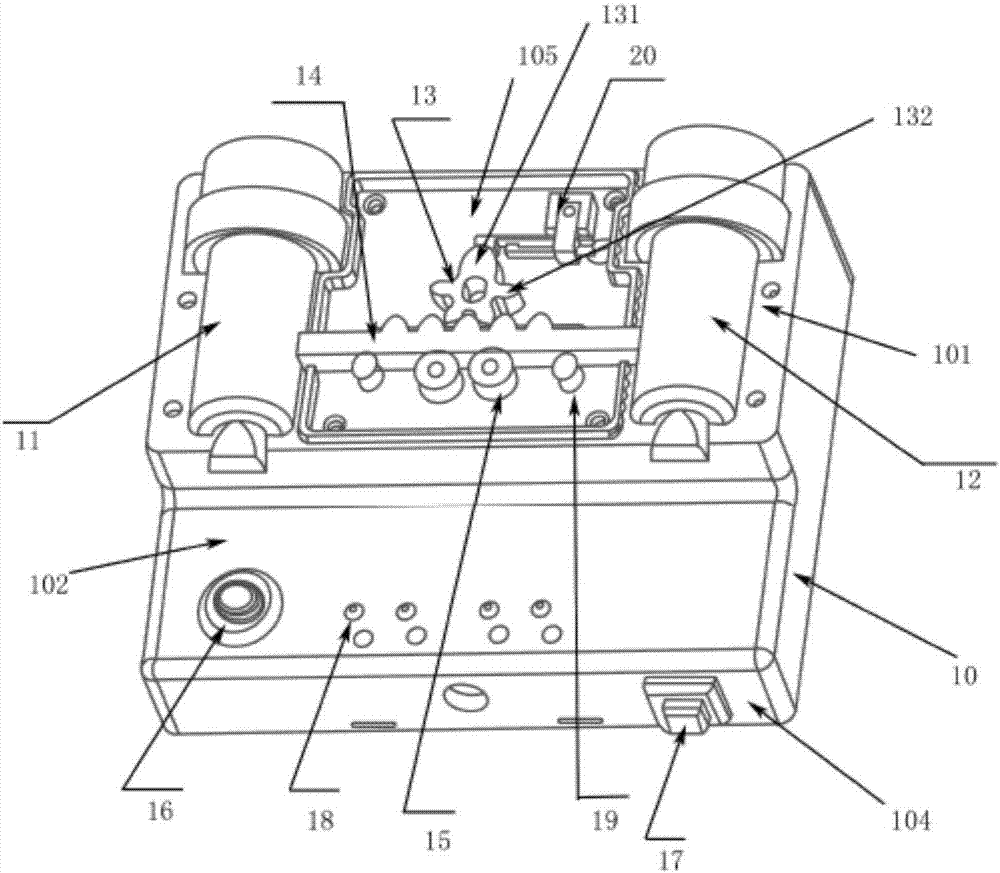

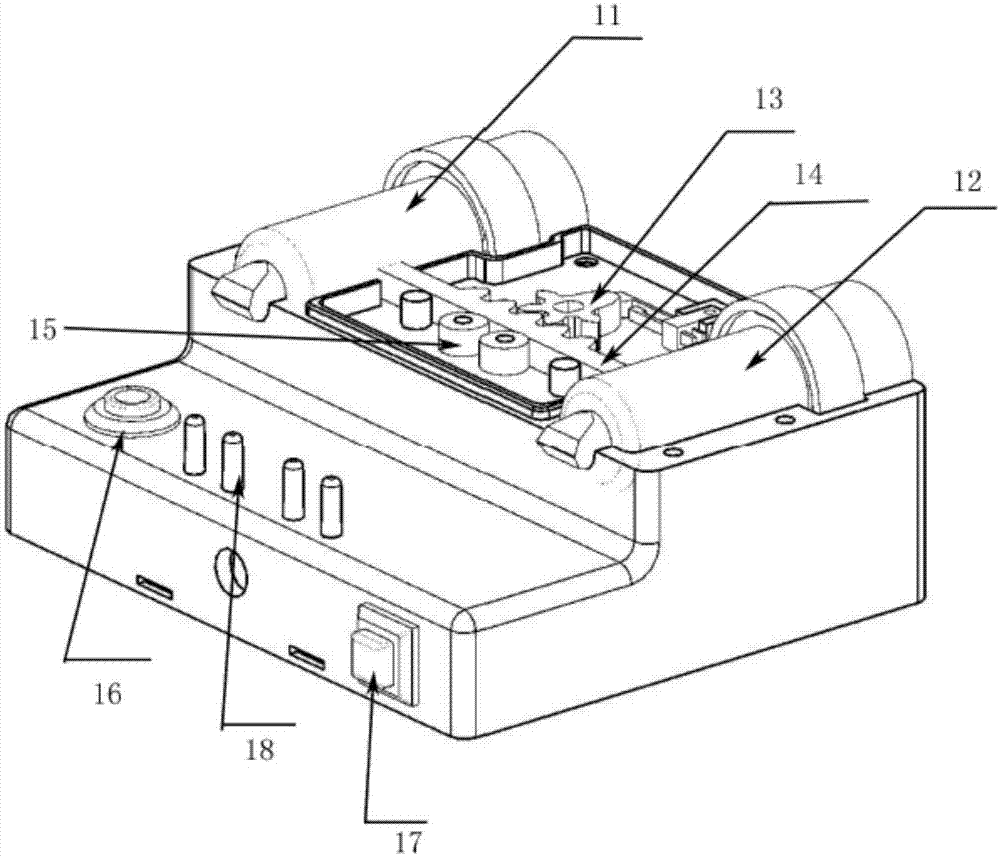

[0035] The automatic extruder provided in this embodiment, such as figure 1 with figure 2 As shown, it at least includes a motor 26 , a transmission gear 13 , a stressed rack 14 , a first silicone rubber tube 11 and a second silicone rubber tube 12 . Preferably, the stressed rack 14 is an elongated structure with gear teeth on one side and a plane on the other side. Preferably, the gears of the transmission gear 13 and the force-receiving rack 14 mesh with each other. Preferably, the gears of the transmission gear 13 and the force rack 14 are externally meshed. Preferably, the gear of the transmission gear 13 and the force-receiving rack 14 are arranged above the force-receiving rack 14 so as to mesh with each other. The upper side of the stressed rack refers to the side with gear teeth of the stressed rack. A guide bearing 15 and a support column 19 are arranged below the load rack 14 in contact with it. The lower side of the force-bearing rack 14 refers to the side of ...

Embodiment 2

[0042] The automatic extruder of the present embodiment is further improved on the basis of embodiment 1. This embodiment provides the circuit connection method of the automatic extruder of the present invention. The lower casing of the automatic extruder has a hollow structure inside. The circuit module and the motor are preferably arranged in the inner hollow of the lower housing.

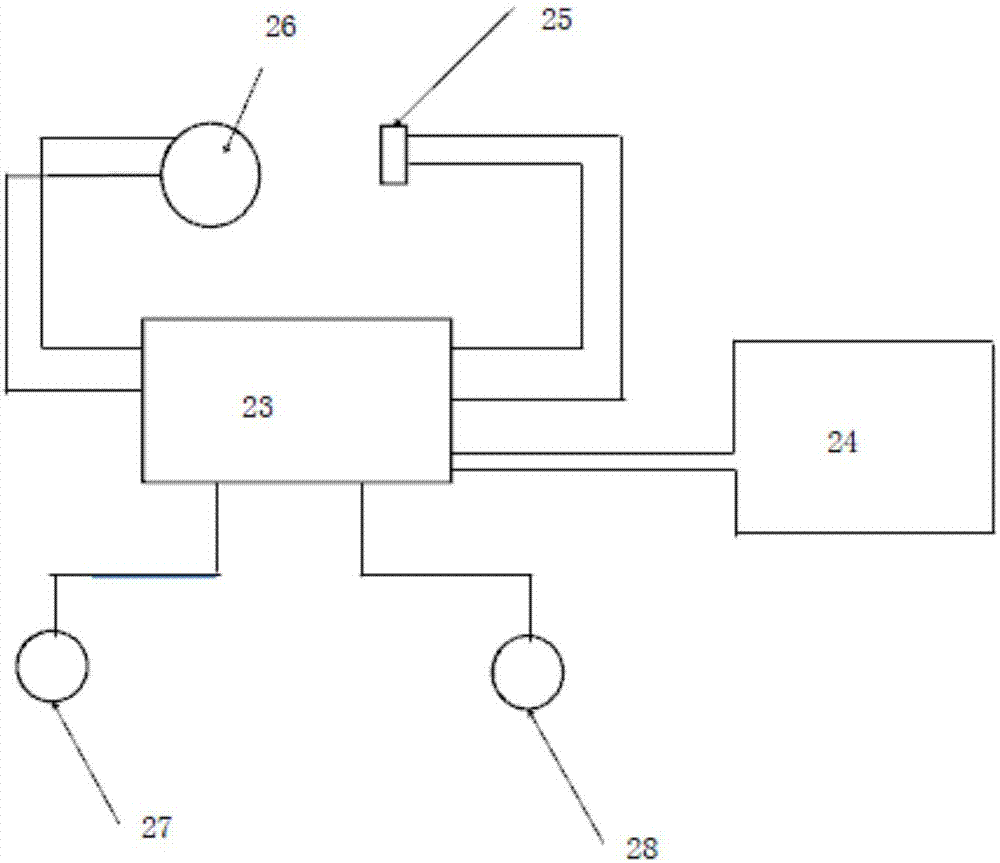

[0043] Such as image 3 with Figure 4 as shown, image 3 shows the connection diagram of the circuit module of the present invention; Figure 4 It is a bottom view of the circuit module of the present invention installed inside the lower casing of the automatic extruder. The circuit module includes a first reset switch 27 , a second reset switch 28 , a control module 23 , a motor 26 , a travel switch circuit 25 and a power supply 24 . A first button 16 and a second button 17 electrically connected to the first reset switch 27 and the second reset switch 28 are arranged on the second upper ...

Embodiment 3

[0047] This embodiment is a further improvement on the basis of Embodiment 1 and Embodiment 2. The first silicone rubber tube 11 and the second silicone rubber tube 12 are placed laterally in the first groove of the lower housing, preferably, the first silicone rubber tube 11 and the second silicone rubber tube 12 can be removed at any time, so that Replace anytime after using up the cosmetics inside the silicone tube.

[0048] refer to Figure 5 to Figure 7 , the first silicone rubber tube 11 and the second silicone rubber tube 12 include a feed rubber tube 113 and a discharge rubber tube 112 located at the lower part of the feed rubber tube 113 . Its material is food grade silicone rubber. The top end of the feeding rubber tube is open and a sealing gasket is reserved, so that the skin care product can be sealed after entering the feeding rubber tube. The bottom of the feeding rubber tube 113 has a first shoulder 115, and the feeding rubber tube 113 is provided with an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com